Two identical stainless steel water bottles side by side - one made from 304 grade and one from 316 grade steel

After 14+ years of manufacturing stainless steel water bottles and working with over 1000 different designs, I've seen firsthand how choosing the wrong steel grade can make or break a product line. The difference between 304 and 316 stainless steel might seem small on paper, but it can mean the difference between satisfied customers and costly returns.

Quick Decision Table

| Factor | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Cost | Standard pricing | 20-40% more expensive |

| Best For | General use, fresh water bottles | Marine environments, premium bottles |

| Corrosion Resistance | Excellent for most applications | Superior in saltwater/chemical exposure |

| Food Safety | FDA approved, LFGB certified | FDA approved, LFGB certified |

| Durability | Great for everyday use | Enhanced durability in harsh conditions |

| Market Position | Standard promotional bottles | Premium/specialized applications |

Introduction: Why This Choice Matters for Your Business

As the founder of Sibottle, I've manufactured millions of water bottles across 120+ countries. In my experience, the biggest mistake buyers make is treating all stainless steel as equal. The grade you choose directly impacts your brand reputation, customer satisfaction, and long-term profitability.

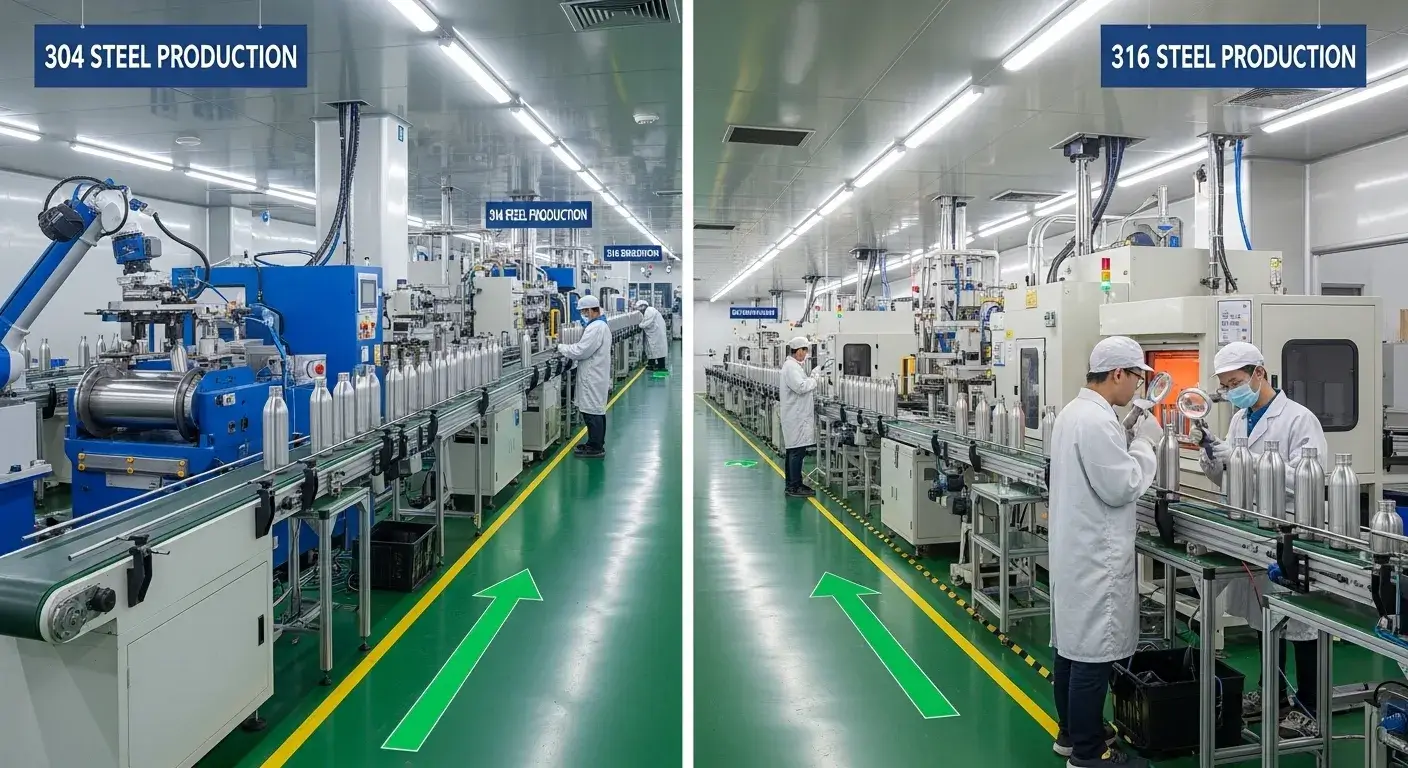

Manufacturing floor showing 304 and 316 stainless steel production lines at our 18,000 square meter facility

When a promotional bottle starts showing rust spots after just three months at a coastal resort, or when a premium brand's products fail under normal use, the problem often traces back to steel grade selection. Through our comprehensive manufacturing guide, I've shared insights from producing over 800,000 bottles daily. This article will help you make the right choice every time.

What Are 304 and 316 Stainless Steel?

Both 304 and 316 stainless steel belong to the austenitic family, which means they're non-magnetic, highly formable, and excellent at resisting corrosion. In our factory, we work with both grades daily, and I can tell you the differences matter more than most buyers realize.

304 stainless steel, often called "18/8 stainless steel," contains 18% chromium and 8% nickel. It's the workhorse of our stainless steel water bottle manufacturing operations - reliable, cost-effective, and perfect for most applications.

316 stainless steel takes performance to the next level with 2-3% molybdenum added to the mix. This small addition transforms its corrosion resistance, especially in challenging environments where regular steel fails.

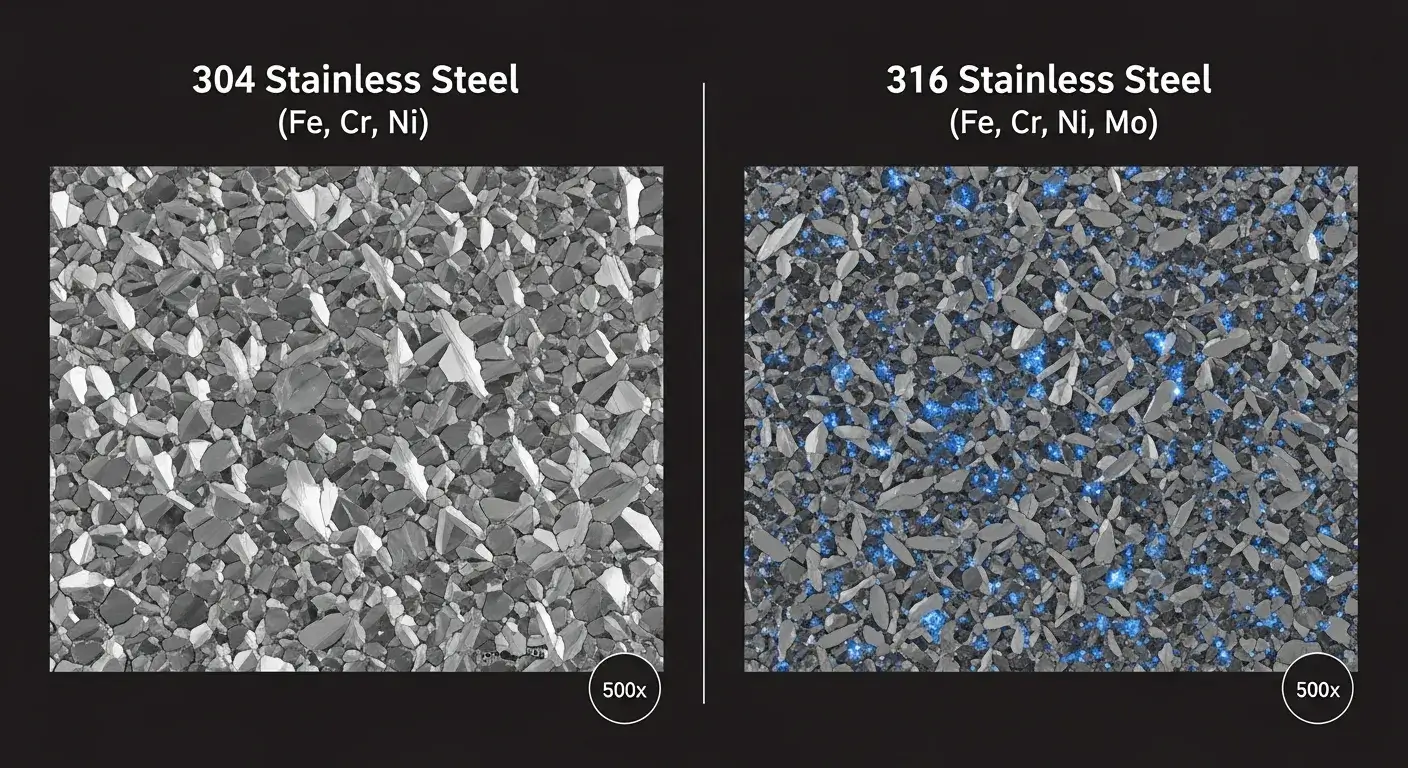

Close-up microscopic view showing the crystalline structure differences between 304 and 316 stainless steel

The One Key Difference That Changes Everything

In my years of testing different steel grades, I've discovered that molybdenum is the game-changer. This element creates a protective barrier against chloride attack, making 316 steel the preferred choice for marine applications according to maritime industry standards.

While both grades look identical to the naked eye, their performance in harsh environments tells a completely different story. The molybdenum in 316 steel forms a secondary protective layer that 304 simply cannot match.

The Chemistry Behind the Performance

The Molybdenum Factor: Why 2-3% Makes All the Difference

| Element | 304 Content (%) | 316 Content (%) |

|---|---|---|

| Chromium | 18-20 | 16-18 |

| Nickel | 8-10.5 | 10-14 |

| Molybdenum | 0 | 2-3 |

| Carbon | ≤0.08 | ≤0.08 |

This chemical difference translates to real-world performance that your customers will notice. The American Society for Testing and Materials (ASTM) has established strict standards for both grades, ensuring consistent performance across manufacturers.

Laboratory setting showing chemical composition analysis of different stainless steel samples

Real-World Impact on Your Products

Through our quality control testing, I've seen how these chemical differences affect bottle performance. The molybdenum in 316 steel creates pitting resistance that's crucial for bottles exposed to chlorinated water, saltwater, or acidic beverages over extended periods.

Corrosion Resistance: Where Your Profits Live or Die

304 Performance: When It Works Perfectly (and When It Fails)

From my manufacturing experience, 304 stainless steel excels in most everyday situations:

- Fresh water applications perform flawlessly

- Coffee, tea, and acidic beverages cause no issues

- Standard cleaning chemicals are handled easily

- Indoor and moderate outdoor environments show excellent durability

However, I've witnessed 304 bottles fail dramatically when exposed to saltwater environments. Even small amounts of chlorides (as little as 25 ppm) can cause pitting corrosion over time, leading to customer complaints and warranty claims.

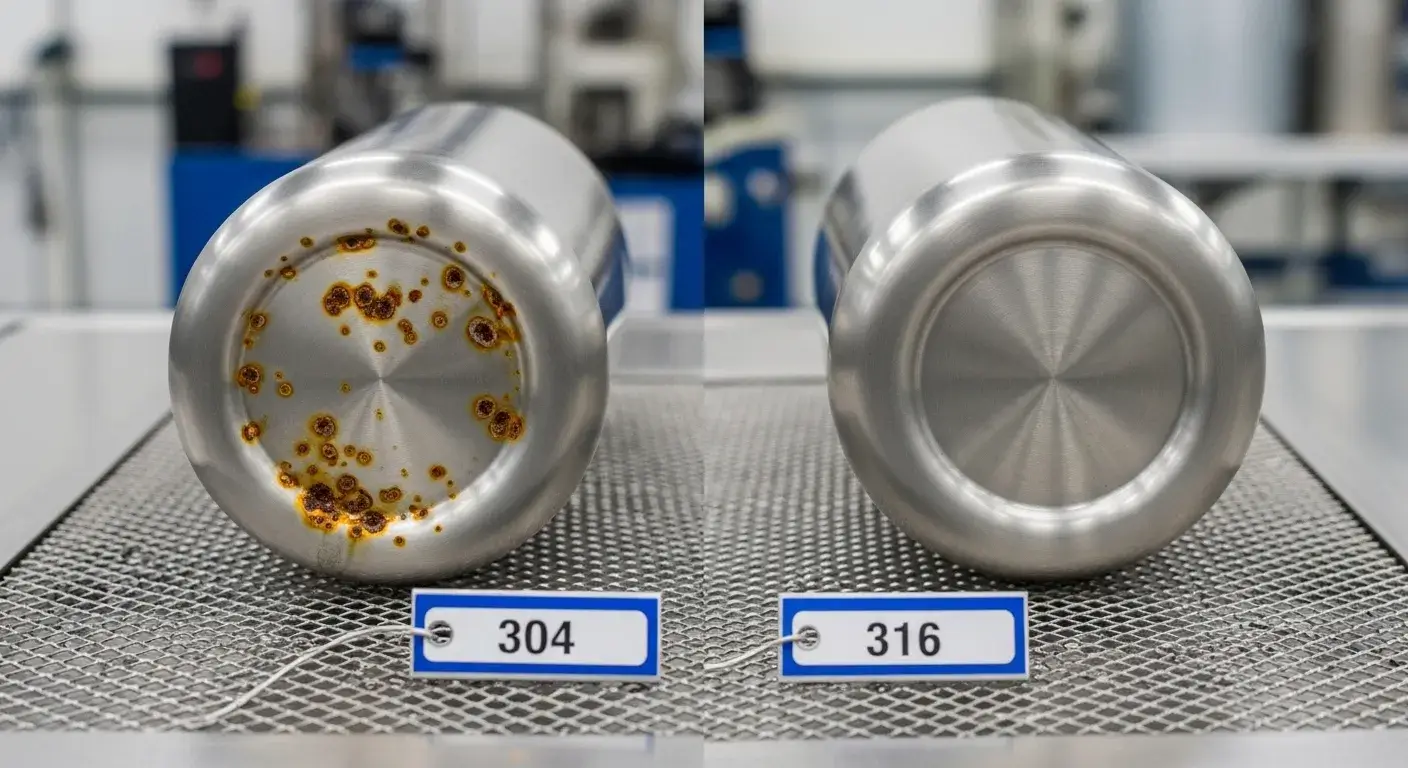

Side-by-side comparison showing corrosion test results of 304 vs 316 steel after saltwater exposure

316 Superiority: The Saltwater Test Every Manufacturer Should Know

316 stainless steel shines where 304 struggles. According to NACE International corrosion studies, the molybdenum content makes it incredibly resistant to:

- Saltwater exposure - perfect for marine applications

- Chloride-rich environments - swimming pools, coastal areas

- Industrial chemicals - pharmaceutical and chemical processing

- Harsh cleaning agents - commercial kitchen environments

Case Study: Why Coastal Customers Need 316

I once had a client who ordered 10,000 promotional bottles in 304 steel for a beachside hotel chain. Within six months, guests were complaining about rust spots and discoloration. We replaced the entire order with 316 steel, and those bottles are still performing perfectly three years later. The lesson? Environment matters more than initial cost savings.

Cost Analysis: Is 316 Worth the Extra Investment?

The price difference between 304 and 316 stainless steel varies significantly based on market conditions. From our purchasing data over the past five years, the premium typically ranges from 20-40%, with commodity price fluctuations affecting both grades.

Real Price Differences (20-40% Premium)

Current market analysis shows:

- 304 bottles: Standard manufacturing costs allow competitive pricing

- 316 bottles: Premium pricing structure justified by enhanced performance

- Volume discounts: Our 1000-piece minimum order quantities help offset some premium costs

Cost comparison chart showing 5-year price trends for stainless steel raw materials

When Cheaper Becomes More Expensive Long-Term

Despite higher upfront costs, 316 stainless steel often provides better value when you factor in:

- Reduced warranty claims in harsh environments

- Enhanced brand reputation for durability

- Access to premium market segments

- Lower long-term replacement costs

My Recommendation for Different Market Segments

Based on our client success stories:

- Budget-conscious promotional campaigns: 304 steel provides excellent value

- Premium brand positioning: 316 steel justifies higher retail prices

- Marine/outdoor markets: 316 steel is essentially mandatory

- Corporate gifting: Grade choice depends on recipient environment

Applications: Matching Steel Grade to Your Market

304 Stainless Steel Applications

In our steel water bottle manufacturing division, we primarily use 304 stainless steel for:

Standard Promotional Bottles

- Office environments with controlled conditions

- Indoor events and conferences

- General consumer market applications

- Cost-sensitive promotional campaigns

Indoor Corporate Gifting

Corporate clients love 304 steel for internal use because it provides professional appearance and durability at reasonable pricing. Our corporate clients typically order 1000-5000 pieces for employee appreciation programs.

General Consumer Market

- Everyday hydration bottles

- School and sports applications

- Basic insulated tumblers

- General food service equipment

Collection of 304 stainless steel water bottles in corporate office setting

316 Stainless Steel Applications

316 stainless steel becomes essential for specialized applications where performance matters more than cost:

Marine Industry Bottles

As detailed in marine industry publications, 316 steel is the standard for:

- Boat accessories and marine hardware

- Coastal resort promotional items

- Surfing and water sports brands

- Beach club merchandise

Premium Outdoor Brands

High-end outdoor companies choose 316 steel because their customers expect maximum durability. These bottles often retail for 40-60% more than standard products, making the material premium worthwhile.

Medical/Pharmaceutical Industries

Our pharmaceutical clients require 316 steel for bottles used in clinical settings where chemical resistance is crucial. The FDA guidelines for medical devices specifically recommend 316L steel for many applications.

316 stainless steel water bottles being used in marine environment with sailing boats in background

Quality Standards and Certifications

Both 304 and 316 stainless steel grades meet identical food safety standards that matter to your customers:

- FDA compliance for food contact surfaces

- LFGB certification for European markets

- Food-grade safety standards worldwide

- BSCI audit compliance through our certified facility

The difference lies not in safety, but in durability and performance longevity. Our quality control processes ensure both grades meet the highest standards regardless of price point.

What Certifications Your Customers Actually Care About

Through customer surveys, I've learned that buyers prioritize:

- Food safety certifications (FDA/LFGB) - Universal requirement

- Durability testing results - Increasingly important for premium brands

- Environmental compliance - Growing concern for corporate buyers

- Manufacturing certifications - ISO9001 provides customer confidence

Manufacturing Insights: What 14 Years Has Taught Me

Production Considerations for Each Grade

Working with both grades across our five automated production lines, I've learned important differences:

304 Stainless Steel:

- Easier machining reduces tool wear

- Faster forming speeds increase production efficiency

- Standard welding techniques work perfectly

- Consistent quality across all thickness ranges

316 Stainless Steel:

- Requires specialized tooling for optimal results

- Slightly slower production speeds due to material hardness

- Enhanced welding procedures ensure joint integrity

- Additional quality control steps verify molybdenum content

Production line comparison showing 304 and 316 steel bottle manufacturing processes

Quality Control Differences

Both grades undergo rigorous testing, but 316 stainless steel requires additional verification steps:

- Chemical composition analysis confirms molybdenum content

- Corrosion resistance testing validates performance claims

- Stress testing ensures enhanced mechanical properties

- Surface finish inspection maintains premium appearance standards

Lead Time Impacts

Our standard 20-25 day lead times apply to both grades when properly planned. However, 316 steel occasionally requires additional processing time during peak demand periods due to specialized handling requirements.

How to Choose: My Decision Framework

After helping thousands of clients select the right grade through our contact process, I use this proven framework:

Choose 304 Stainless Steel When:

- Budget constraints are primary concern

- End-use involves controlled indoor environments

- Volume requirements exceed 5000 pieces

- Market positioning targets cost-conscious consumers

- Application involves minimal environmental stress

Choose 316 Stainless Steel When:

- Product faces marine or coastal environments

- Brand positioning emphasizes premium quality

- Customers value maximum durability over cost

- Application involves chemical or saltwater exposure

- Long-term cost benefits outweigh initial investment

Budget Considerations

Based on current pricing, here's how the grades affect your budget:

- 304 steel: Allows competitive retail pricing for mass market appeal

- 316 steel: Supports premium pricing strategy with enhanced margins

- Mixed orders: Some clients order 80% 304 and 20% 316 for market testing

Target Market Analysis

Your target market directly influences grade selection:

- Corporate buyers: Often prefer 304 for cost control

- Outdoor enthusiasts: Expect 316 performance and pay accordingly

- Promotional companies: Usually choose 304 unless client specifies otherwise

- Premium brands: Require 316 for brand consistency

Environmental Factors

Environmental exposure determines appropriate grade selection:

- Indoor use: 304 steel provides excellent performance

- Outdoor activities: 316 steel ensures customer satisfaction

- Marine environments: 316 steel is essentially mandatory

- Industrial settings: Grade depends on specific chemical exposure

Brand Positioning Strategy

Your brand positioning affects customer expectations:

- Value brands: 304 steel maintains competitive pricing

- Premium brands: 316 steel reinforces quality messaging

- Luxury brands: 316 steel is expected standard

- Niche markets: Grade selection varies by specific application

Common Mistakes I See Buyers Make

Choosing Based on Price Alone

The biggest mistake in my experience is focusing solely on initial cost. I've seen companies lose customers and damage reputations by choosing cheaper grades for inappropriate applications. The total cost of ownership includes warranty claims, replacement costs, and brand reputation impact.

Ignoring End-Use Environment

A bottle that performs perfectly in an office environment might fail catastrophically at a beach resort. Always consider where customers will actually use your products, not just where they'll buy them.

Overlooking Customer Expectations

Premium brands require premium materials. Your steel grade choice communicates your values before customers even touch the product. Misaligned grade selection can undermine years of brand building.

Frequently Asked Questions

Which is better for promotional bottles?

For most promotional applications, 304 stainless steel provides the perfect balance of quality and cost-effectiveness. However, if your promotional campaign targets outdoor or marine markets, 316 steel offers superior performance that justifies the premium pricing.

Will my customers notice the difference?

Customers won't see visual differences initially, but they'll absolutely notice performance differences in challenging environments. 316 stainless steel maintains appearance and function longer under stress, leading to higher customer satisfaction scores.

How does this affect customization options?

Both grades accept identical customization techniques through our insulated steel tumbler manufacturing processes:

- Laser engraving works equally well on both grades

- Color coating adhesion is comparable

- Screen printing results are identical

- Custom packaging options remain the same

What about lead times and MOQ?

Our standard specifications apply to both grades:

- Lead time: 20-25 days for both 304 and 316 steel

- Minimum order: 1000 pieces regardless of grade selection

- Mixed orders: You can combine grades in single orders

- Rush orders: Available for both grades with advance planning

How does this affect the environment?

Both steel grades are 100% recyclable according to the Steel Recycling Institute, making them environmentally responsible choices. The longevity of 316 steel can actually reduce environmental impact by extending product life cycles.

Infographic showing environmental benefits and recycling process of stainless steel water bottles

Conclusion: Making the Right Choice for Your Business

The decision between 304 and 316 stainless steel ultimately comes down to matching your product requirements with customer expectations and environmental conditions. Throughout my 14+ years in manufacturing, I've learned that the right grade choice today prevents expensive problems tomorrow.

For most water bottle applications, 304 steel provides exceptional performance at competitive pricing. It's food-safe, durable, and meets the expectations of general consumers while supporting healthy profit margins.

For specialized applications - marine environments, premium brands, or harsh-use conditions - 316 stainless steel offers superior protection that differentiates your brand and justifies premium pricing.

The key is understanding your specific application requirements and choosing accordingly. Both grades offer excellent value when properly matched to their intended use.

Ready to Make Your Decision?

At Sibottle, we've helped thousands of companies choose the right stainless steel grade for their applications. Our team responds to all inquiries within 12 hours, and we're always happy to discuss which grade best fits your specific needs.

Whether you need 1000 pieces for market testing or 100,000 pieces for a major launch, our five automated production lines and 120+ staff members ensure consistent quality and on-time delivery. Visit our comprehensive manufacturing guide for additional technical information, or contact our team to discuss your project requirements.

Don't let the wrong steel grade choice compromise your brand reputation. The difference between satisfied customers and costly returns often comes down to this single decision. Let our 14+ years of experience guide you to the right choice for your business success.