Worried about water tank safety? Many are unsure if stainless steel is truly safe for long-term storage. Let's clear it up.

Stainless steel water tanks are safe for storing potable water when made from certified food-grade materials like SUS304 or SUS316 and manufactured to hygienic standards.

This article explores the materials, standards, and maintenance needed to ensure water stays safe in stainless steel tanks.

What Are Stainless Steel Water Tanks?

You see them everywhere, but how safe are they really?

Stainless steel water tanks are durable storage systems made from steel plates, used to store drinking water safely.

How They Work

These tanks are common in homes, factories, and cities. They resist corrosion1 and can last decades with proper care.

Types of Stainless Steel Used in Water Tanks (304 vs 316)?

Not all stainless steels are the same.

SUS304 and SUS316 are the most used grades in water tanks. 316 is more corrosion-resistant and ideal for saline or harsh environments.

Comparison Table

| Grade | Features | Best Use |

|---|---|---|

| 304 | Affordable, corrosion-resistant | Most residential & indoor tanks |

| 316 | Better corrosion resistance2 (molybdenum) | Industrial or coastal locations |

Choosing the right grade is crucial for long-term water safety and tank durability.

Material Standards and Certifications Ensuring Safety?

How do you know the tank is really safe?

Look for compliance with standards like GB/T3280 for stainless steel and NSF/ANSI 61 for potable water.

Key Certifications

- GB/T3280: Chinese national standard3 for stainless steel plates

- NSF/ANSI 61: U.S. standard4 ensuring materials don't leach harmful substances into water

- ASME / API 650: Design and pressure standards for larger or pressurized tanks

These labels mean the tank has passed safety tests.

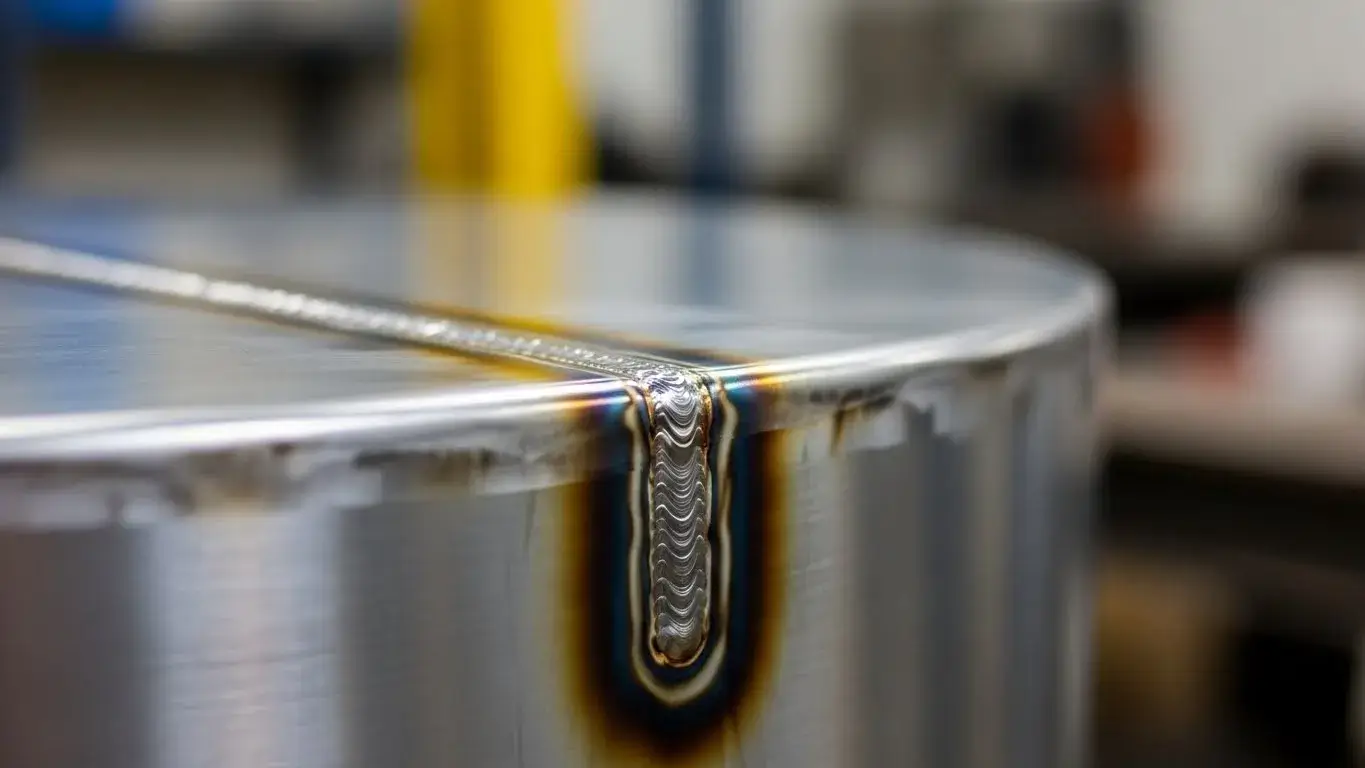

Manufacturing and Welding Quality: Impact on Water Safety?

How it's made matters.

High-quality welding using gas-shielded methods and polished seams prevents leaks and bacterial buildup.

Good Welding Matters

- Flat, polished seams: No spots for dirt or bacteria

- Gas-shielded methods5: Prevent contamination during construction

Poor welding can compromise tank integrity and water safety.

Hygiene and Corrosion Resistance of Stainless Steel Tanks?

Clean water starts with clean tanks.

Stainless steel is naturally hygienic and resists rust, making it a top material for water storage.

Why Stainless Steel?

- Non-porous surface6: No place for bacteria to grow

- No coatings: No risk of chemical leaching

- Self-healing oxide layer: Prevents rust7

SUS316 is especially useful in tough water conditions like saltwater.

Compliance with Health and Environmental Regulations?

Following rules keeps water safe and the environment clean.

Certified tanks meet building codes and environmental regulations, protecting both health and ecosystems.

Compliance Requirements

- ASME Section VIII: For pressure tanks

- API 650: For large field-erected tanks

- Local codes8: Define safety for installation, material, and inspection

These rules help avoid pollution and health risks.

Installation Best Practices for Safe Water Storage?

Even the best tank fails if poorly installed.

Secure anchoring, leak-proof piping, and professional setup protect your tank and your water.

Installation Tips

- Avoid sharp tools that may damage the surface

- Ensure ground is level and load-bearing

- Use certified installers9 for large tanks

This step is often overlooked but essential for long-term safety.

Maintenance and Inspection to Prevent Contamination?

Even stainless steel needs upkeep.

Annual inspections and cleaning keep your water safe and your tank strong.

Inspection Tools

- Ultrasonic Testing (UT)10: Detects internal corrosion

- Radiographic Testing: Finds weld flaws

- Visual Checks: Look for stains, leaks, or sediment

Cleaning every 6–12 months prevents bacterial growth and sediment buildup.

Comparing Stainless Steel Tanks with Other Materials?

Is stainless steel really better?

Compared to plastic and concrete, stainless steel is more durable, hygienic, and environmentally friendly.

Comparison Table

| Material | Lifespan | Hygiene | Maintenance |

|---|---|---|---|

| Stainless Steel | 20–50 years | Excellent | Low |

| Plastic | 10–20 years | Moderate | Medium |

| Concrete | 30–50 years | Variable | High (can crack or leach) |

In the long run, stainless steel often offers the best total value11.

Common Concerns and Myths About Stainless Steel Water Tanks?

Are the fears real?

Fears of rust or leaching are myths—when proper grades and standards are followed, stainless steel is one of the safest materials available.

Debunked Myths

- "Steel will rust!" Not if it's 304/316 stainless.

- "Tanks leach metal!" Certified stainless steel is non-leaching12.

- "Too expensive!" Costs more upfront, but lasts longer13.

Buy certified tanks from trusted manufacturers to avoid risks.

Conclusion

Stainless steel water tanks are safe when made from food-grade materials and installed correctly, offering a durable and hygienic solution.

Frequently Asked Questions

Are stainless steel water tanks safe for drinking water?

Yes. When made from 304 or 316 stainless steel and certified, they are safe for potable water.

What grade of stainless steel is used for water tanks?

304 is standard; 316 is used in more corrosive environments.

How long do stainless steel water tanks last?

20 to 50 years, depending on environment and maintenance.

Do stainless steel water tanks rust or corrode?

Rarely. They resist corrosion, especially if 316 grade is used.

What certifications ensure tank safety?

NSF/ANSI 61, ASME Section VIII, API 650, and GB9684.

How should stainless steel tanks be maintained?

Regular inspection and cleaning every 6–12 months.

Are they better than plastic or concrete?

Yes. They're more hygienic, durable, and eco-friendly.

Can stainless steel tanks contaminate water?

Not if made with certified food-grade material and maintained well.

What installation practices ensure safety?

Level base, certified materials, professional welding and sealing.

How often should they be inspected?

At least once a year, or as required by local regulations.

Footnotes:

-

Stainless steel forms a protective passive layer through chromium and oxygen interaction, providing excellent corrosion resistance even in saltwater environments. Source: Ulbrich Stainless Steel Technical Guide ↩

-

Grade 316 stainless steel contains 2-3% molybdenum, which significantly enhances resistance to chlorides and pitting corrosion compared to 304. Source: Reliance Foundry Industry Reference ↩

-

GB/T3280 is China's national standard specifying requirements for cold-rolled stainless steel plates, sheets, and strips used in corrosion-resistant applications. Source: Code of China Standards ↩

-

NSF/ANSI 61 establishes minimum health effects requirements for materials in contact with drinking water systems, preventing harmful chemical leaching. Source: NSF International Standards Library ↩

-

Gas-shielded welding (TIG/MIG) protects the weld pool from atmospheric contamination, preventing oxidation and ensuring corrosion-resistant weld integrity. Source: Alleima Welding Technical Center ↩

-

Stainless steel's smooth, non-porous surface prevents bacterial adhesion and makes sanitization more effective than porous materials. Source: Clickmetal Industry Reference ↩

-

The chromium oxide passive layer on stainless steel is self-healing—when scratched, it naturally reforms when exposed to oxygen. Source: Team Stainless Association ↩

-

Plumbing codes vary by jurisdiction but typically require licensed professionals for water system installations to ensure safety compliance. Source: ServiceTitan Industry Guide ↩

-

Licensed plumbers must meet state certification requirements including apprenticeship completion and examination to perform water system installations. Source: Washington State Department of Labor & Industries ↩

-

Ultrasonic testing uses high-frequency sound waves to measure material thickness and detect internal corrosion without damaging the tank structure. Source: American Society for Nondestructive Testing ↩

-

Stainless steel tanks provide superior long-term value through 50+ year lifespans, lower maintenance costs, and full recyclability compared to plastic or concrete alternatives. Source: Beltecno Global Industry Analysis ↩

-

Food-grade stainless steel (304/316) does not leach harmful chemicals into beverages under normal use conditions, unlike some plastics. Source: Splitflask Product Safety Guide ↩

-

Over a 45-50 year lifespan, stainless steel water tanks cost significantly less than concrete tanks when factoring installation, repairs, and removal costs. Source: ModuTank Cost Comparison Analysis ↩