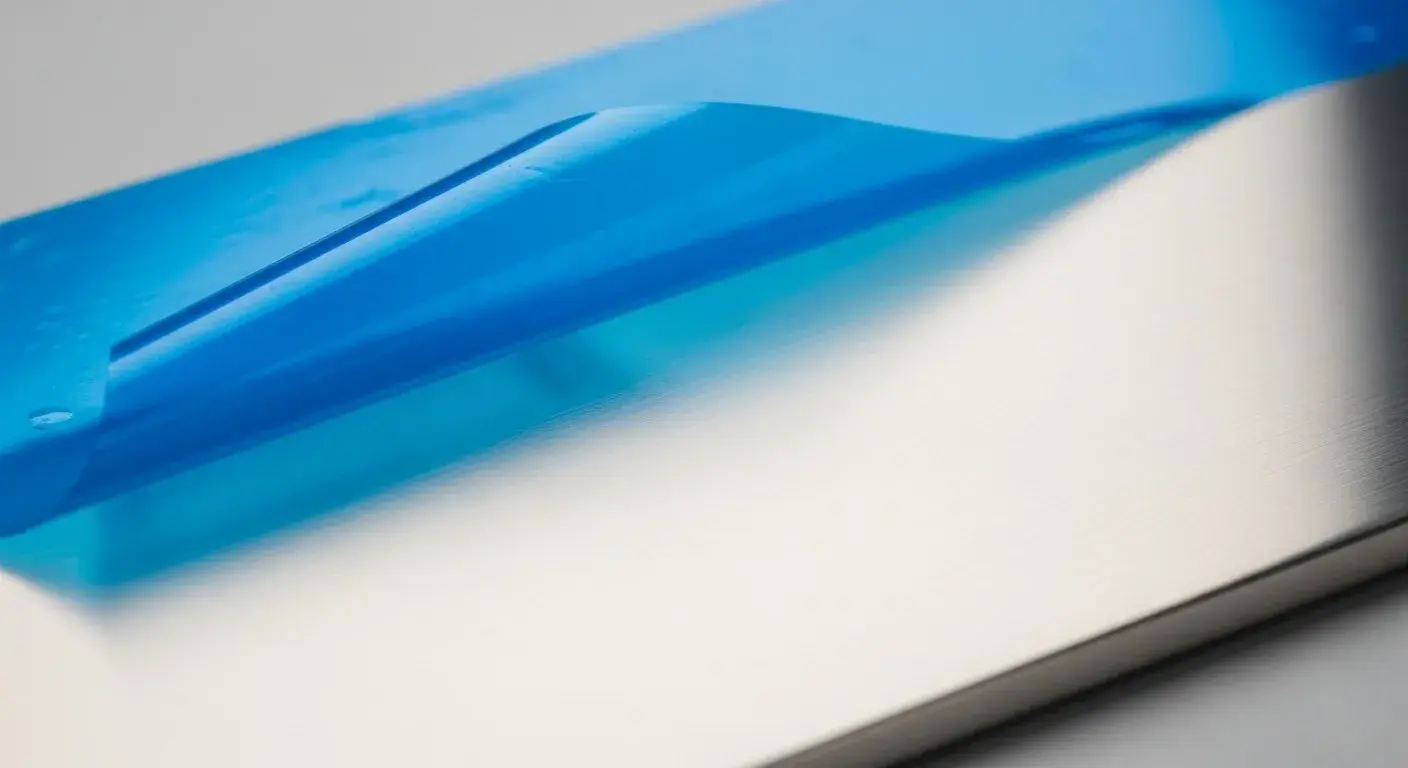

Stuck plastic film on metal is more than annoying—it damages aesthetics and slows production. Many solutions fail without the right prep.

Plastic coatings on metal can be removed using manual tools, heat, or solvents, depending on the material and coating age.

Removing plastic film requires care. Learn effective and safe methods from home hacks to industrial techniques.

Why is plastic coating applied to metal surfaces?

Plastic coatings protect metal during storage and transport. But they can be hard to remove if they age or overheat.

Plastic films shield metal from scratches, corrosion, and dirt1. However, they may harden or bond tightly over time.

Common Applications

- Stainless steel appliances

- Aluminum panels for construction

- Sheet metal during fabrication

Benefits and Issues

| Purpose | Benefit | Long-Term Issue |

|---|---|---|

| Transport | Scratch protection | Difficult peeling later |

| Storage | Corrosion resistance | Adhesive residue on removal |

| Manufacturing | Finish preservation | Bubbles or film tearing |

What challenges arise when removing plastic coatings from metal?

Old or heat-exposed coatings cling tightly. Tools can scratch surfaces, and adhesive residues often remain.

Challenges include strong adhesion, tearing films, adhesive residues, and potential surface damage2.

Common Removal Issues

- Film cracks or tears

- Sticky residue left behind

- Scratches from hard tools

Factors That Affect Difficulty

- Coating age

- Sunlight or heat exposure

- Type of adhesive used

What are the safest and most effective tools for peeling off plastic film from metal?

Use plastic razor blades, nylon trim tools, or putty knives to peel film without damaging metal.

Plastic tools gently lift coatings without scratching metal surfaces3, making them ideal for manual removal.

Tool Comparison Table

| Tool | Safe for Metal | Effectiveness | Notes |

|---|---|---|---|

| Plastic razor blade | ✅ | Moderate | Works well on smooth panels |

| Putty knife (plastic) | ✅ | High | Requires steady hand |

| Nylon trim tool | ✅ | Moderate | Used in auto body work |

| Metal scraper | ❌ | Very High | Risks surface scratches |

Can heat help in loosening plastic coatings on metal?

Yes. Heat guns or steam soften plastic and adhesives, making it easier to peel or roll off.

Controlled heat weakens film and adhesive4, easing removal without harming the metal.

Heat Application Tips

- Use low to medium settings (avoid warping)

- Hold 6–10 inches from surface

- Test on small areas first

Are there chemical solvents that can dissolve or weaken plastic coatings safely?

Yes, but they must be used cautiously. Acetone and adhesive removers work but can be harsh.

Solvents like acetone dissolve glue residues5. Always test first and use protective gear.

Common Solvents

| Solvent | Effectiveness | Safe on Stainless Steel | Notes |

|---|---|---|---|

| Acetone | High | ✅ | Fast-acting but flammable |

| Paint thinner | Moderate | ✅ | Good for adhesives |

| Goo Gone | Moderate | ✅ | Gentle but slower |

How do you remove stubborn adhesive residue after peeling off the plastic?

After film removal, scrub gently with solvent and cloth. Repeat as needed.

Use solvent-dampened cloth to wipe off glue6, then rinse with mild soap and water.

Step-by-Step

- Peel off main plastic layer

- Apply solvent to leftover adhesive

- Let sit 1–2 minutes

- Scrub with cloth or sponge

- Rinse thoroughly and dry

What precautions should be taken to avoid damaging the metal surface?

Avoid sharp tools. Test solvents on hidden spots. Always wear gloves and work in ventilated spaces.

To protect metal, use non-abrasive tools, control heat, and avoid harsh chemicals7.

Safety Checklist

- ✅ Wear gloves and mask

- ✅ Use plastic or soft tools

- ✅ Work in open or ventilated area

- ❌ Don’t use sandpaper or steel wool

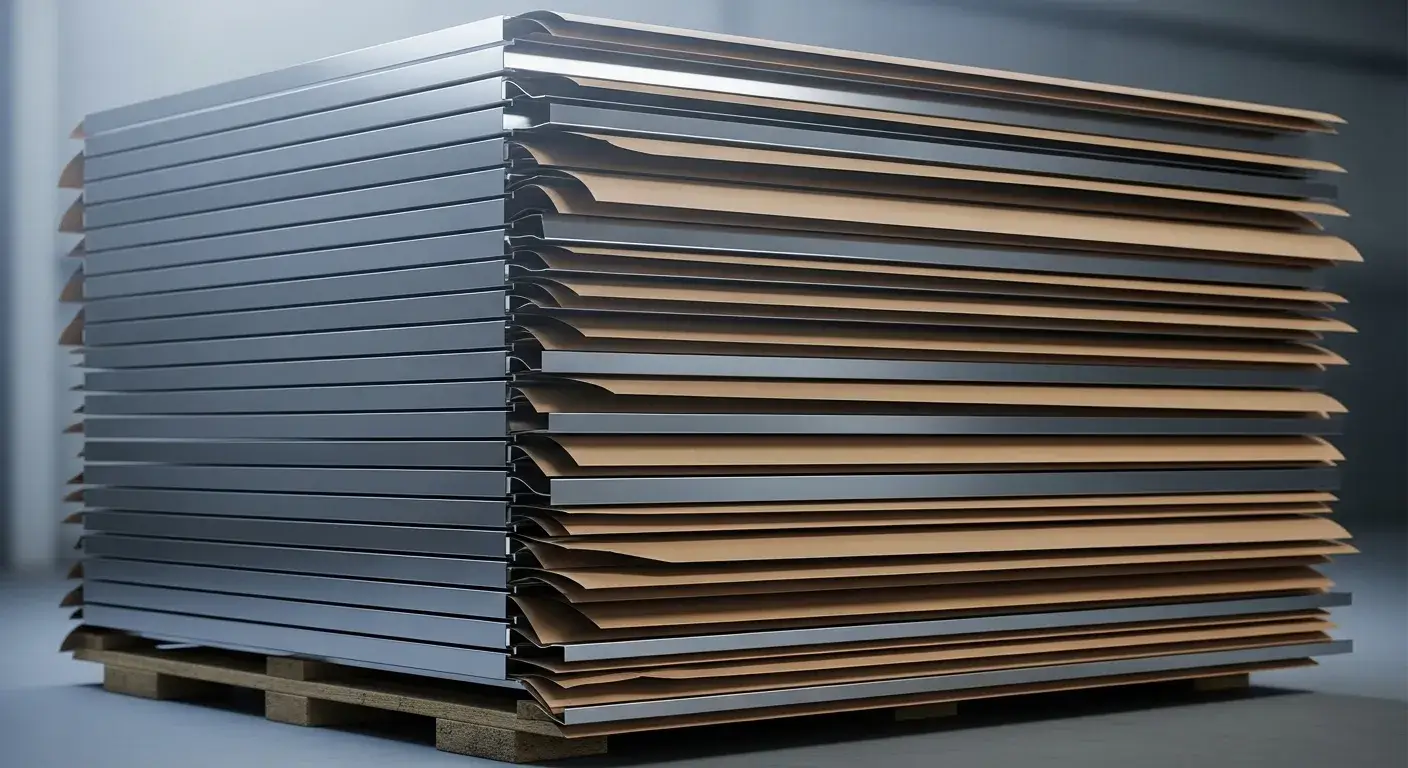

Are there industrial or large-scale methods for removing plastic coating efficiently?

Yes. Use rolling methods or request alternative coatings during production.

Industrial methods include mechanical film rolling and using paper interleaves8 to avoid plastic film.

Large-Scale Solutions

- Use rollers to wind off film efficiently

- Apply controlled steam stripping

- Specify “paper interleave” instead of film for future orders

How can you prevent plastic coatings from sticking too strongly during manufacturing?

Choose easy-peel films or paper coatings during sourcing. Avoid storing coated metal in high heat.

Prevent problems by specifying removable films9 and avoiding heat buildup in storage.

Preventive Tips

- Request “easy peel” film

- Store in cool, dry areas

- Use paper interleaves for stainless steel

What are some DIY tips for removing plastic coatings from small metal parts?

Use heat from hair dryers, ice for melted plastic, or petroleum jelly for gentle removal.

DIY methods like heat or cold soften the film10. Plastic scrapers and oils help lift stuck areas.

DIY Methods

- Apply petroleum jelly overnight

- Use ice cubes to harden melted plastic, then chip off

- Rub gently with baking soda paste

Conclusion

To remove plastic from metal safely, use plastic tools, heat, and solvents. Avoid scratching and test methods carefully.

FAQs

Can I use acetone on stainless steel?

Yes, but test first. Use with caution and wipe dry immediately.

What is the best way to remove melted plastic?

Use ice to harden, then peel or scrape gently with plastic tools.

Is there a way to prevent film sticking during production?

Yes. Request paper interleaves or easy-peel films from your supplier.

Does Goo Gone work on plastic adhesive?

Yes, it works well on most glues but may need repeated applications.

Footnotes:

-

Explains the purpose and benefits of plastic coatings on metal surfaces ↩

-

Highlights why plastic coatings can be difficult to remove once aged or sun-exposed ↩

-

Overview of non-scratch tools ideal for safe film removal ↩

-

Details how heat helps loosen plastic films for safer peeling ↩

-

Lists effective solvents for breaking down plastic adhesives ↩

-

Step-by-step adhesive removal using common safe methods ↩

-

Covers safety measures to avoid damaging metal finishes ↩

-

Describes professional-scale options for bulk or industrial removal ↩

-

Preventative sourcing tips to avoid film bonding issues in future production ↩

-

DIY techniques for small-scale or home-based plastic film removal ↩