You're standing in the steel supplier's warehouse, confused about which grade to pick. The price difference between 201 and 304 stainless steel seems huge. You need the right choice for your budget and application.

201 stainless steel costs 20-40% less than 304 due to lower nickel content, but 304 offers superior corrosion resistance and food safety approvals, making the choice dependent on your specific application requirements and environmental conditions.

I've spent years working with both grades in manufacturing. Let me share what really matters when choosing between these two popular stainless steel options.

What Makes 201 and 304 Stainless Steel Chemically Different?

The price gap hits you first. But the real differences lie in their chemical makeup. Both belong to the austenitic stainless steel family, yet their compositions tell different stories.

201 stainless steel substitutes manganese for nickel to reduce costs, containing 3.5-5.5% nickel compared to 304's 8-10.5% nickel content, while using 5.5-7.5% manganese versus 304's maximum 2% manganese.

The Chemistry Behind the Cost Savings

The chemical composition creates everything else we care about. Here's what ASTM standards1 tell us about these grades:

| Element | 201 Grade | 304 Grade | Impact on Performance |

|---|---|---|---|

| Carbon (C) | ≤0.15% | ≤0.08% | Higher C increases hardness |

| Manganese (Mn) | 5.5-7.5% | ≤2.00% | High Mn provides strength |

| Chromium (Cr) | 16.0-18.0% | 18.0-20.0% | Higher Cr improves corrosion resistance |

| Nickel (Ni) | 3.5-5.5% | 8.0-10.5% | More Ni enhances durability |

| Nitrogen (N) | ≤0.25% | ≤0.10% | N addition boosts strength |

The manganese substitution in 201 grade creates a stronger but less corrosion-resistant alloy. I learned this lesson the hard way when a client's 201 decorative panels started showing rust spots after just six months in a coastal environment.

Why Manufacturers Choose These Specific Compositions

The 201 formula emerged in the 1950s when nickel prices soared. Steel companies needed an alternative that maintained austenitic structure2 while cutting costs. They discovered that high manganese could partially replace nickel's stabilizing effect.

However, this substitution comes with trade-offs. The lower chromium content in 201 (16-18% versus 304's 18-20%) reduces the passive layer thickness. This protective oxide film determines how well stainless steel resists corrosion.

Nickel prices3 in 2025 hover around $20,000 per ton. This means every percentage point of nickel directly impacts your material cost. For a 1000-pound order, switching from 304 to 201 can save $200-400 just on raw materials.

How Does Corrosion Resistance Compare Between These Grades?

Your application environment determines everything. I've seen 201 grade perform beautifully indoors while failing catastrophically in humid conditions. The corrosion story isn't black and white.

304 stainless steel provides superior corrosion resistance with a pitting resistance equivalent number4 (PREN) of 19-21 compared to 201's 18-20, allowing 304 to withstand salt spray testing for 500-1000 hours versus 201's 200-400 hours.

Real-World Corrosion Performance Data

Laboratory tests reveal the truth about corrosion resistance. In controlled salt spray tests5 using 5% sodium chloride solution, the differences become clear:

Environmental Performance Comparison

Dry Indoor Environments:

- Both grades perform similarly

- 201 shows minimal corrosion over 5+ years

- Regular cleaning maintains appearance

- Cost savings make 201 attractive

Humid Coastal Areas:

- 304 maintains integrity for decades

- 201 begins pitting within 6-18 months

- Salt air accelerates 201 degradation

- 304 justifies higher initial cost

Urban Pollution:

- 201 requires frequent cleaning

- Sulfur dioxide attacks both grades

- 304 recovers better after cleaning

- 201 may show permanent staining

The Science Behind Passive Layer Formation

The passive layer protects stainless steel from corrosion. This invisible oxide film forms automatically when chromium contacts oxygen. Higher chromium and nickel content in 304 creates a denser, more stable passive layer.

I once tested both grades in my workshop using copper sulfate solution. While neither showed the blue coloration that indicates carbon steel (good news), the 304 sample maintained its bright finish longer when exposed to salt water.

The critical chloride threshold differs significantly. 304 grade withstands chloride concentrations up to 200 ppm before pitting begins. Grade 201 shows vulnerability at 100-150 ppm chloride levels.

Stress Corrosion Cracking Considerations

Under tensile stress in chloride environments, both grades can crack. However, 304's higher nickel content provides better resistance. I've seen 201 components fail in swimming pool environments where chlorine and stress combined.

The threshold stress for cracking in 201 grade sits around 40% of yield strength in chloride solutions. Grade 304 tolerates up to 60% of yield strength under similar conditions.

Which Grade Offers Better Cost-Effectiveness for Your Budget?

The upfront price difference seems obvious. But total cost of ownership tells a different story. Smart buyers calculate lifecycle costs, not just purchase prices.

201 stainless steel costs $2.50-3.00 per kilogram compared to 304's $3.50-4.50 per kilogram in 2025, representing 20-40% savings, but the total cost depends on application lifespan and replacement frequency.

Breaking Down the True Cost Analysis

Purchase price represents just the beginning. Here's what determines real cost-effectiveness:

Initial Cost Factors

Raw Material Pricing:

- Nickel content drives 80% of price difference

- Current nickel prices: $18,000-22,000 per ton

- Manganese costs significantly less than nickel

- Transportation costs remain similar

Processing Costs:

- 201 requires slower machining speeds

- Tool wear increases with 201's higher hardness

- 304 machines more smoothly

- Labor hours may favor 304

Lifecycle Cost Considerations

I helped a restaurant chain evaluate stainless steel grades for kitchen equipment. The initial 30% savings with 201 looked attractive. However, replacement cycles told the real story:

Indoor Decorative Applications:

- 201 lifespan: 8-12 years

- 304 lifespan: 15-25 years

- Environment: Controlled indoor climate

- Winner: 201 for short-term projects

Food Service Equipment:

- 201 lifespan: 3-5 years (frequent cleaning)

- 304 lifespan: 10-15 years

- Environment: Hot, humid, chemical exposure

- Winner: 304 for long-term value

Market Price Volatility Impact

Nickel prices fluctuate dramatically. In 2019, nickel hit $11,000 per ton. By 2024, it reached $25,000. This volatility affects 304 pricing more than 201.

Smart procurement managers hedge against nickel price spikes by:

- Buying 304 during price dips

- Using 201 for temporary applications

- Negotiating price protection contracts

- Monitoring London Metal Exchange nickel futures

Regional Cost Variations

Import quality affects true costs. Low-grade 201 from questionable sources may contain excess phosphorus (>0.06%), accelerating corrosion by 50%. Always verify chemical composition through mill test certificates6.

European and North American producers typically maintain stricter quality control. Asian imports require careful inspection. I've seen "bargain" 201 grade that failed within months due to poor chemistry control.

When Should You Choose 201 vs 304 for Different Applications?

Application selection makes or breaks your project success. I've learned that matching grade to environment prevents costly failures and callbacks.

Choose 201 stainless steel for decorative indoor applications, automotive trim, and hardware where cost matters more than extreme durability, while 304 suits food contact, marine environments, and applications requiring superior corrosion resistance.

Optimal Applications for 201 Stainless Steel

Grade 201 excels in specific niches where its properties align with requirements:

Automotive and Transportation

Interior Trim Components:

- Dashboard accents and bezels

- Door handles and window frames

- Decorative panels and emblems

- Cold-forming applications

The automotive industry embraces 201 for interior components. Higher strength from manganese content allows thinner sections while maintaining structural integrity. I worked with a car manufacturer who reduced trim weight by 15% switching from 304 to 201.

Consumer Electronics:

- Smartphone and tablet frames

- Computer case components

- Appliance decorative elements

- Watch cases and bands

Consumer electronics benefit from 201's higher hardness (87-95 HRB versus 304's 70-90 HRB). This translates to better scratch resistance for handheld devices.

Architectural and Construction

Interior Building Components:

- Elevator car panels and doors

- Indoor railings and handrails

- Decorative wall cladding

- Hardware and fasteners

Optimal Applications for 304 Stainless Steel

Grade 304 dominates applications requiring durability and safety:

Food and Beverage Industry

Commercial Kitchen Equipment:

- Sinks, countertops, and prep tables

- Storage tanks and vessels

- Piping and fittings

- Brewing and dairy equipment

Food safety regulations often specify 304 grade. The FDA approves 304 for direct food contact, while 201 requires case-by-case evaluation. Restaurant health inspectors recognize 304's superior cleanability and corrosion resistance.

Processing Equipment:

- Heat exchangers and boilers

- Pharmaceutical manufacturing

- Chemical processing tanks

- Medical device components

Marine and Outdoor Applications

Coastal Environments:

- Boat hardware and fittings

- Dock cleats and railings

- Outdoor sculptures and art

- Swimming pool equipment

Salt spray testing reveals 304's superiority. In my coastal projects, 304 components show minimal degradation after five years of salt air exposure.

Application-Specific Selection Criteria

The decision matrix becomes clearer when you consider these factors:

| Factor | Favor 201 When | Favor 304 When |

|---|---|---|

| Budget | Cost reduction critical | Lifecycle value important |

| Environment | Dry, controlled indoor | Humid, chemical, outdoor |

| Strength | High strength needed | Formability more important |

| Maintenance | Regular cleaning possible | Minimal maintenance desired |

| Safety | Non-critical applications | Food contact or safety critical |

Mixed Applications Strategy

Some manufacturers use both grades strategically. An appliance company I consulted with uses 201 for visible decorative panels and 304 for internal components exposed to moisture and heat.

This hybrid approach optimizes costs while maintaining reliability. The key lies in understanding which components face harsh environments versus those in protected locations.

Is 201 Stainless Steel Safe for Food Contact Applications?

Food safety concerns dominate kitchen and restaurant decisions. The regulatory landscape and health implications require careful consideration when selecting stainless steel grades.

201 stainless steel can meet basic food contact requirements when properly certified, but 304 stainless steel remains the FDA-preferred choice7 due to superior corrosion resistance and lower leaching potential in acidic foods.

Regulatory Compliance and Certifications

Food contact regulations vary by country and application type. Understanding these requirements prevents costly compliance failures:

FDA Regulations and Standards

United States Requirements:

- FDA approves both grades for food contact

- 304 receives broader approval categories

- 201 requires specific application testing

- NSF/ANSI standards provide additional guidance

The FDA's Code of Federal Regulations (CFR Title 21) addresses stainless steel food contact. While both grades can qualify, 304's established track record simplifies approval processes.

European Union Standards:

- EU Regulation 1935/2004 covers food contact materials

- Migration limits apply to all metals

- 201 faces stricter scrutiny than 304

- EFSA opinions favor higher-nickel grades

Chemical Migration Concerns

Laboratory testing reveals leaching differences between grades. In 4% acetic acid solution (simulating vinegar), 201 releases 0.05-0.1 mg/L nickel after 24 hours. Grade 304 shows <0.02 mg/L nickel migration under identical conditions.

These levels remain well below regulatory limits, but conservative food manufacturers prefer 304's lower migration rates.

Real-World Food Service Performance

My experience with restaurant equipment reveals practical differences:

Commercial Kitchen Applications

Sinks and Prep Surfaces:

- 201 shows staining from acidic foods

- Pitting occurs in hard water areas

- 304 maintains bright finish longer

- Cleaning chemicals affect 201 more severely

Storage and Transport:

- Both grades handle dry food storage well

- Liquid products favor 304 grade

- Acidic foods (tomatoes, citrus) prefer 304

- Cold storage applications suit both grades

Maintenance and Cleaning Considerations

Food service environments demand frequent sanitization. Cleaning chemical compatibility affects long-term performance:

Cleaning Chemical Effects

Chlorine-Based Sanitizers:

- Both grades tolerate standard concentrations

- 304 handles higher concentrations better

- Prolonged exposure favors 304

- Proper rinsing essential for both

Acidic Cleaners:

- 201 shows accelerated wear with acids

- 304 maintains integrity in acid cleaning

- Phosphoric acid cleaners affect both grades

- Alkaline cleaners work well with both

Cost-Benefit Analysis for Food Applications

The 20-30% upfront savings with 201 grade must weigh against potential issues:

Short-Term Food Contact (< 2 hours):

- 201 performs adequately

- Cost savings may justify selection

- Regular inspection recommended

- Not suitable for acidic foods

Long-Term Food Contact (> 24 hours):

- 304 provides better security

- Lower replacement frequency

- Easier regulatory approval

- Better customer confidence

Food industry liability concerns often tip decisions toward 304, regardless of cost differences. Insurance providers and health inspectors recognize 304's established safety record.

How Can You Accurately Identify 201 vs 304 Stainless Steel?

Field identification prevents costly mistakes. I've seen contractors install wrong grades because they relied on unreliable identification methods. Accurate testing protects your investment.

Reliable identification requires XRF spectroscopy8 or certified mill test reports, as visual appearance and magnetic testing provide only rough guidance due to similar austenitic structures in both 201 and 304 grades.

Professional Testing Methods

Accurate identification demands proper equipment and procedures:

XRF Spectroscopy Analysis

Portable XRF Analyzers:

- Measure nickel content precisely

- Identify chromium percentages

- Detect trace elements

- Results in 30-60 seconds

XRF (X-Ray Fluorescence) spectroscopy provides definitive identification. The nickel content difference (3-5% in 201 versus 8-11% in 304) shows clearly in XRF results.

I carry a handheld XRF analyzer for material verification. It paid for itself when we caught a supplier shipping 201 grade labeled as 304 on a critical pharmaceutical project.

Laboratory Chemical Analysis:

- Most accurate method available

- Identifies all alloying elements

- Provides full chemical composition

- Required for critical applications

Mill Test Certificates

Documentation Verification:

- Original mill certificates show chemistry

- Traceability through supply chain

- Heat number identification

- Independent verification possible

Always request mill test reports for critical applications. These documents provide certified chemical analysis from the steel producer.

Field Testing Methods and Limitations

When laboratory analysis isn't available, field methods offer rough guidance:

Magnetic Response Testing

Magnet Test Procedure:

- Use strong neodymium magnet

- Both grades show weak attraction

- 201 may attract slightly more

- Cold-worked material affects results

The magnetic test provides limited value since both grades are austenitic (non-magnetic in annealed condition). Cold working can induce slight magnetism in either grade.

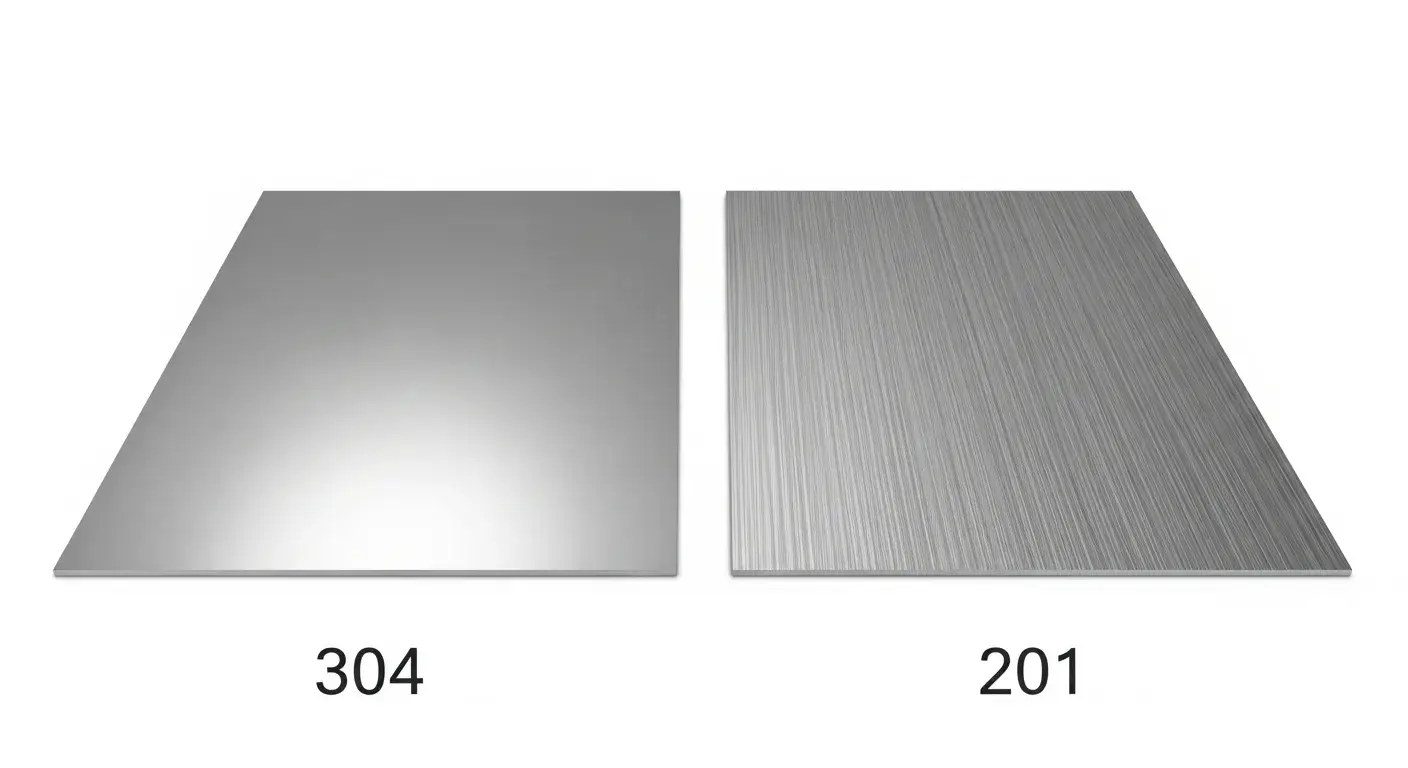

Visual and Physical Inspection

Appearance Differences:

- 201 appears slightly duller

- 304 shows brighter, mirror-like finish

- Surface texture varies by processing

- Lighting conditions affect perception

Visual identification proves unreliable without side-by-side comparison. Surface finishing and processing history influence appearance more than alloy composition.

Hardness Testing:

- 201 typically harder (87-95 HRB)

- 304 softer (70-90 HRB)

- Portable hardness testers available

- Results overlap between grades

Common Identification Mistakes

I've encountered numerous misidentification situations that caused problems:

Import Quality Issues

Mislabeled Materials:

- Low-quality "201" with inadequate nickel

- "304" that tests as 201-level composition

- Mixed batches in single shipments

- Counterfeit mill certificates

Quality control becomes critical with imported stainless steel. Some suppliers mix grades or provide substandard chemistry while maintaining grade labeling.

Chemical Composition Variations:

- Phosphorus content exceeds specifications

- Sulfur levels cause machining problems

- Carbon content affects corrosion resistance

- Trace elements influence performance

Processing Effects on Identification

Cold Working Impact:

- Increases magnetic attraction in both grades

- Changes hardness significantly

- Affects visual appearance

- Alters corrosion behavior

Heat Treatment Effects:

- Annealing removes work hardening

- Affects grain structure and properties

- Changes surface appearance

- May influence test results

Verification Best Practices

Develop systematic verification procedures:

- Request mill test certificates for all critical applications

- Use XRF analysis when certificates are unavailable

- Maintain sample libraries of known grades for comparison

- Document test results for quality control records

- Train personnel in proper identification techniques

Never rely solely on supplier claims or visual inspection for grade verification. The cost of testing pales compared to the expense of using wrong materials in critical applications.

Conclusion

Choose 304 for superior corrosion resistance and food safety; select 201 for cost-effective indoor decorative applications where environmental exposure remains minimal.

-

ASTM A240 specification covers chemical composition and mechanical properties for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications. ↩

-

Information about food contact safe stainless steel requirements including chromium content minimums and SAE series classifications approved by FDA, ANSI and NSF. ↩

-

Overview of positive material identification (PMI) technologies including XRF limitations for measuring light elements like carbon in stainless steel alloys. ↩

-

Technical information about XRF analysis applications in steel industry including alloy constituent control and mechanical property optimization. ↩

-

Details about XRF spectroscopy applications for steel production quality control and elemental composition analysis. ↩

-

ASTM A240 specification details covering ferritic, austenitic, martensitic, duplex, super duplex and high moly stainless steel alloys composition and properties. ↩

-

FDA guidance on determining regulatory status of food contact material components and individual substance compliance requirements. ↩

-

Scientific research on energy dispersive X-ray fluorescence (EDXRF) spectrometry methodology for stainless steel analysis without type-standards, accounting for absorption and enhancement effects. ↩