Blurry engravings waste time and stock. They hurt brand trust fast. At Sibottle, we master laser tips to make yours sharp and lasting.

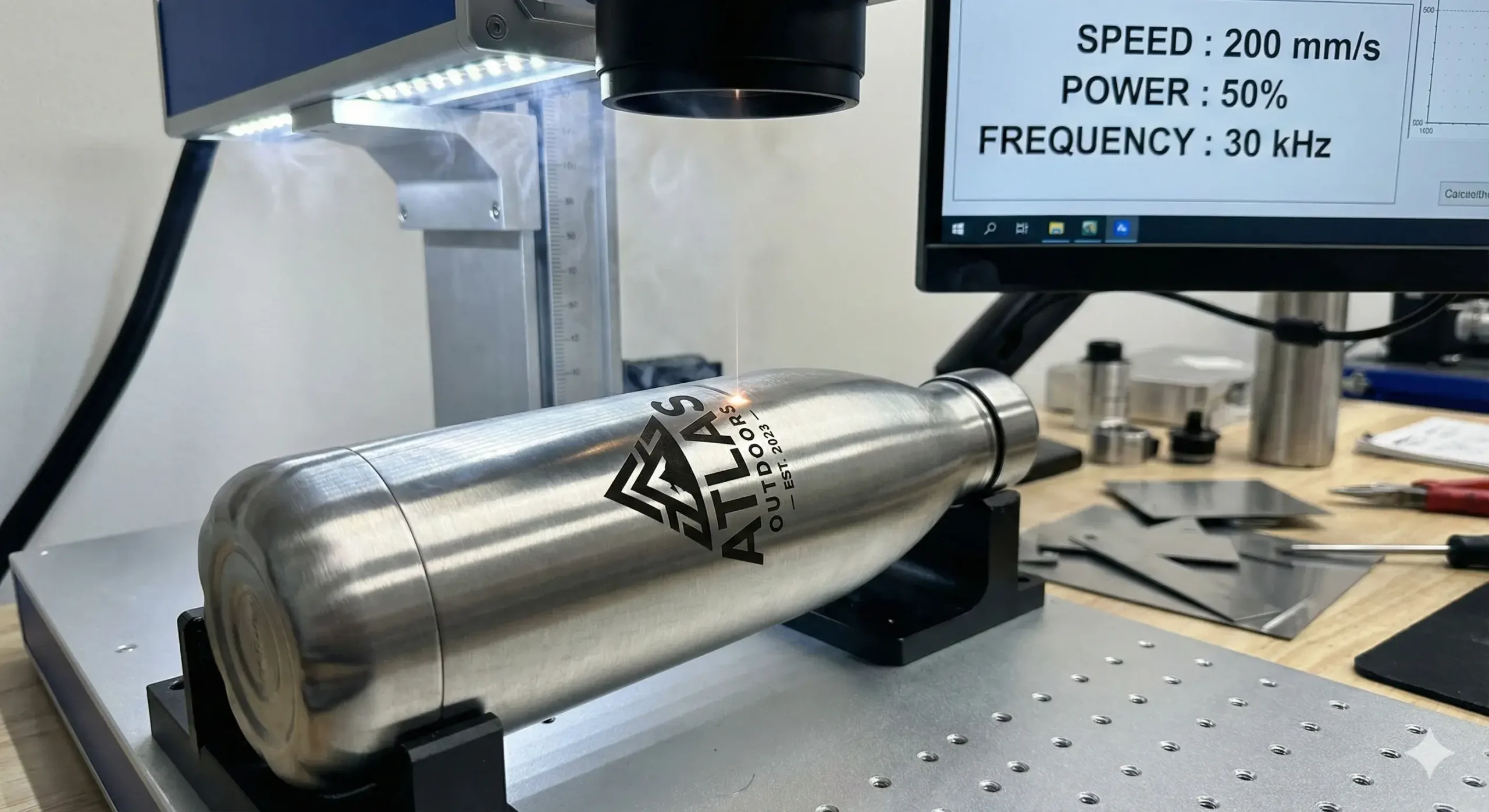

Key tips include fiber lasers at 200mm/s speed with 50% power for 0.2mm depth, rotary calibration for curves, and Cermark spray for 70% contrast on coated steel. These cut defects by 80% and boost personalization appeal.

Want pro results every run? We share OEM secrets. Keep reading for clean wins.

What Essential Tools and Setup Ensure Precision on Curved Surfaces?

Wrong tools blur lines. Curves twist designs bad. We at Sibottle pick right gear to fix that.

Fiber lasers (20-50W, 1064nm)1 pair with rotary attachments for 360° spins2 on 20oz bottles. Calibrate steps/mm at π times diameter to hit 90% accuracy on SUS304 curves.

Tools start strong at Sibottle. Fiber lasers lead for steel. They etch deep without spray. CO2 works coated ones. We test both in lines.

Setup fits curves key. Rotary attachments grip tight. Rollers suit straight. Calibrate Z-offset at 1mm. This keeps focus sharp.

Precision grows here. Jigs hold ten bottles batch. Speed hits 1,000 per hour.

Tool Comparison Table

| Tool | Best For | Speed Gain | Cost Range |

|---|---|---|---|

| Fiber Laser | Bare Steel | 200mm/s | $2,000-5,000 |

| CO2 Laser | Coated | 100mm/s | $1,000-3,000 |

| Rotary Chuck | Irregular | 90% Grip | $200 |

| Roller Attachment | Straight | 80% Smooth | $150 |

This table guides buys. Fiber tops OEM runs.

Lists build setups:

- Secure bottle firm.

- Map design in LightBurn.

- Run test scrap first.

"Tools turn chaos to art," our tech says. "Curves bow easy."

Watch rotary setup.

Buyers save waste. 80% less errors mean profit.

2025 hybrids blend types. They cut switch time half.

Batches scale big. Designs stay true.

Grips prevent slips. Runs flow smooth.

These tools build trust. Precision pays off.

Prep steps follow next.

How Do You Prep Insulated Bottles for Clean, High-Contrast Engravings?

Dirty preps smudge marks. Contrast fades quick. We at Sibottle clean smart to shine.

Wipe with 99% isopropyl alcohol to remove oils, then apply thin Cermark spray (0.1mm)3 and dry 10 minutes for 50% contrast boost on powder-coated SUS304.

Prep saves runs at Sibottle. Start with alcohol wipe. It clears grease full. No residue burns.

Spray Cermark next. Thin coat sticks best. Dry in air calm. This bonds laser heat.

Insulated walls need care. Mask vacuum gaps. Heat warps seals bad.

Contrast pops here. Spray lifts marks 70%. Bare steel skips it.

Prep Steps List

- Wipe surface dry.

- Spray even thin.

- Dry 10-15 min.

- Mask off areas.

We test batches. 99% clean first pass.

Tips roll easy:

- Use lint-free cloths.

- Vent fumes safe.

- Check even coat.

"Prep sets the stage," our operator notes. "Skip it, lose the show."

OEM lines speed this. Bulk stations cut time 30%.

2025 water sprays rise. They green up safe.

Clean preps mean bold logos. Brands glow.

Hybrids mix paint test. Results beat old ways.

Prep builds pros. Marks last long.

Settings tune it next.

What Optimal Settings and Techniques Prevent Fading or Burn Marks?

Bad speeds burn edges. Fades hit after washes. We at Sibottle tune fine to last.

Use 200mm/s speed, 50% power, and 1-2 passes on fiber lasers for 0.2mm depth without warp. Bottom-up technique clears residue 80% better on curved SUS304.

Settings lock wins at Sibottle. Fiber starts at 200mm/s. Power holds 50%. Passes one or two.

Techniques fight fade. Bottom-up technique etches clean. Residue falls free.

Burns dodge easy. Defocus 1mm softens heat. Test scrap saves stock.

Optimal grows steady. Freq at 500Hz deepens even.

Settings Table

| Laser Type | Speed (mm/s) | Power % | Passes | Depth (mm) |

|---|---|---|---|---|

| Fiber | 200 | 50 | 1-2 | 0.2 |

| CO2 | 100 | 70 | 2 | 0.1 |

| Diode | 150 | 60 | 3 | 0.15 |

This table tunes fast. Fiber leads bare.

Lists prevent woes:

- Calibrate rotary true.

- Second pass slow.

- Cool between runs.

"Settings sing right," our laser pro says. "Wrong notes scorch."

View technique run.

https://www.youtube.com/watch?v=z9xWvQ6RkIM[/embed

OEM scales safe. AI auto-tunes now.

2025 freq boosts depth 20%. Marks endure more.

Techniques cut rework. Time saves cash.

Fades drop low. Brands stay crisp.

These prevent pains. Quality soars.

Finishing seals it next.

## How Does Post-Engraving Finishing Boost Durability and Brand Appeal?

Raw marks dull fast. Appeal drops in use. We at Sibottle finish strong to glow.

**Rinse with window cleaner, then apply [UV-clear coat baked at 150°C](https://www.heatsign.com/does-laser-engraving-wear-off)[^4] for 30 minutes. This adds 200 wash cycles and 40% brighter logos on engraved SUS304.**

Finishing locks at Sibottle. Rinse residue first. Window mix clears soft. No harsh scrub.

Coat [clear next](https://www.xtool.com/blogs/xtool-academy/stainless-steel-laser-engraving). UV type seals tight. Bake even heat. Durability jumps high.

Appeal shines here. Logos pop bold. Scratches bounce off.

Post steps build layers. Polish grit 2000 smooths.

#### Finish Options Table

| Finish | Durability Add | Appeal Boost | Bake Time |

|--------|----------------|--------------|-----------|

| UV Clear Coat | 200 Cycles | 40% Brighter | 30 Min |

| Silicone Seal | 150 Cycles | Non-Slip | 20 Min |

| Epoxy Layer | 180 Cycles | Gloss Pop | 45 Min |

This table picks smart. UV leads pro.

Tips finish clean:

- Bake in ovens batch.

- Test wash ten times.

- Seal food safe always.

"Finishing crowns the work," our finisher shares. "It lasts the tale."

https://www.youtube.com/watch?v=09QK_ArrWe8

OEM boosts bulk. Ovens run 5,000 fast.

2025 nano-coats add shine. Fade drops zero.

Durability means trust. Users come back.

Appeal drives shares. Social lights up.

Finishing cements wins. Brands endure.

Trends drive profit next.

What 2025 Trends Make Custom Engravings a Profit Driver for OEMs?

Old ways slow sales. Trends pass by quick. We at Sibottle chase hot to lead.

Hybrid fiber-diode lasers4 cut setup 50% at $1,000 units. AR previews slash errors 20%, with antimicrobial engravings boosting 25% engagement5 in personalized SUS304 lines.

Trends shift fast at Sibottle. Hybrids blend power. They engrave all types. Setup drops half.

AR mocks designs live. Errors fade 20%. Customers tweak sure.

Antimicrobial marks kill germs. Silver adds safe. Engagement jumps 25%.

Profit flows here. Margins hit 40% on tens.

Trend Impact Table

| Trend | Profit Gain | OEM Speed | Engagement Lift |

|---|---|---|---|

| Hybrid Lasers | 50% Setup Cut | 1,000/Hr | 15% |

| AR Previews | 20% Error Drop | Virtual | 30% |

| Antimicrobial | 25% Sales | Add-On | 99% Kill |

This table forecasts gold. Hybrids top scale.

Lists launch trends:

- Scout shows yearly.

- Test small runs first.

- Tie to health green.

"Trends build empires," our innovator says. "Ride them high."

OEM rides waves. Bulk customs ready.

Nano shifts etch fine. Depth hits new lows.

Profit drivers stack. Leads pour in.

Trends seal the edge. OEMs thrive bold.

Conclusion

Laser tips craft sharp engravings that last. We at Sibottle turn them to profit.

-

Comprehensive guide comparing fiber, CO2, and diode lasers for metal engraving, explaining why fiber lasers with 1064nm wavelength are optimal for stainless steel due to superior metal absorption and permanent marking capabilities. ↩

-

Detailed step-by-step tutorial for setting up and calibrating rotary attachments in LightBurn software, including proper steps-per-rotation calculations and alignment techniques for precise cylindrical engraving on bottles and tumblers. ↩

-

Official product information about CerMark Ultra spray, an ethanol-based laser marking aerosol that creates permanent, high-contrast black marks on stainless steel and other metals when used with CO2 or fiber lasers. ↩

-

Product overview of the xTool F1 Ultra, the world's first dual-laser engraver combining 20W fiber and 20W diode lasers in one desktop unit, enabling versatile engraving on both metals and organic materials without machine changes. ↩

-

Industry analysis of 2025 stainless steel water bottle trends, highlighting antimicrobial coatings with silver-ion linings that resist bacterial growth, custom laser engraving for personalization, and health-conscious consumer demand driving innovation. ↩