When it comes to finding a reliable Chinese insulated steel water tumbler manufacturer, the options can feel endless. With the growing demand for high-quality drinkware, China has become a global hub for tumbler production. However, not all manufacturers are created equal, and choosing the right partner is crucial to ensure product quality, affordability, and a seamless supply chain.

To choose the best Chinese insulated steel water tumbler manufacturer, focus on their production quality, certifications, manufacturing capacity, communication transparency, and customer service. Evaluating these factors can save you time and guarantee that you’re partnering with a dependable supplier.

In this guide, we’ll walk through key questions and considerations that will help you assess potential manufacturers and select a trusted partner in the Chinese market.

Why Should You Choose a Chinese Manufacturer for Insulated Steel Water Tumblers?

China dominates the insulated tumbler market, offering competitive prices, advanced manufacturing technology, and extensive experience in drinkware production. But beyond affordability, what are the key benefits of partnering with a Chinese manufacturer?

Choosing a Chinese manufacturer provides cost savings, a wide range of customization options, and access to advanced manufacturing techniques.

Chinese manufacturers have mastered insulated tumbler technology, including vacuum sealing and double-wall insulation, which are essential for maintaining temperature in high-quality tumblers. Their facilities often use advanced machinery, allowing for precision manufacturing at scale. Additionally, Chinese factories can offer unique customization options for branding, color, and design, which are crucial for companies looking to stand out. Check out our guide on the Benefits of Vacuum Insulation Technology for more details on how this feature enhances product quality.

Claims:

Up to 50% cost savings compared to Western manufacturers.

Access to advanced production methods such as laser etching and custom insulation materials.

Variety of materials and customization for unique branding needs.

What Certifications Should a Reputable Manufacturer Have?

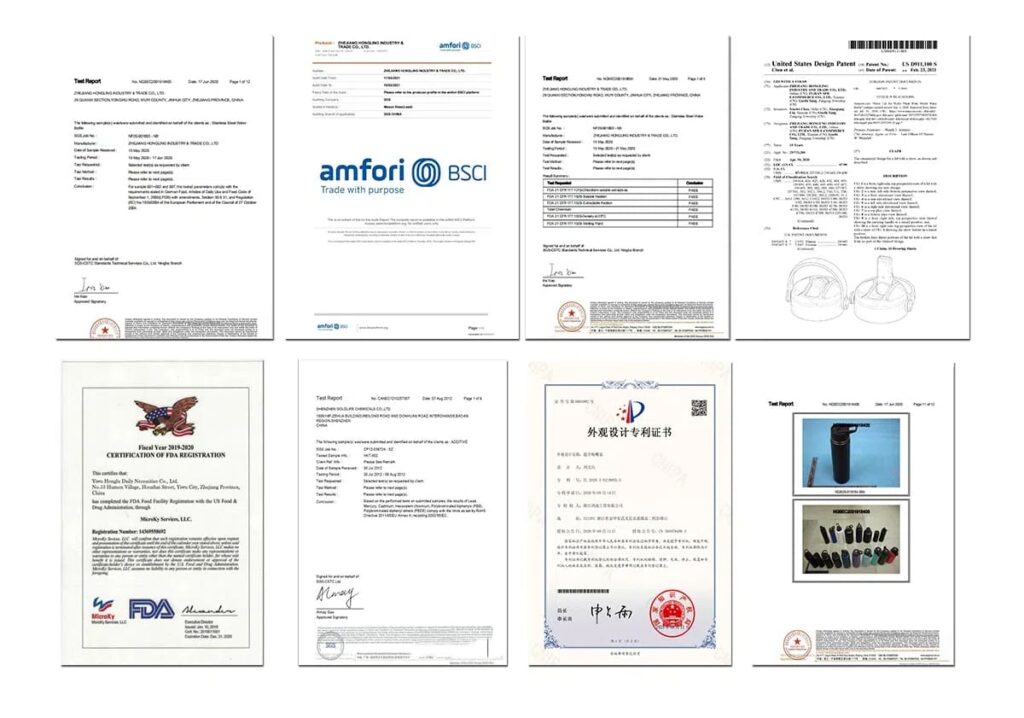

Certifications are an essential criterion when evaluating any manufacturing partner, especially in a regulated industry like drinkware. Certifications indicate adherence to safety, quality, and ethical standards, ensuring that products meet international requirements.

Look for ISO 9001, FDA approval, LFGB certification, and BSCI compliance when choosing a manufacturer.

ISO 9001 certification indicates a strong quality management system, while FDA and LFGB certifications show that the materials are safe for food contact. BSCI compliance is also important, especially for companies prioritizing ethical and responsible manufacturing practices. These certifications not only ensure safety but also reflect the manufacturer’s commitment to high standards. Visit our Product Safety and Certification Guide to understand how each certification impacts product quality and customer trust.

Claims:

ISO 9001: Ensures quality management processes.

FDA and LFGB: Certify food-safe materials.

BSCI: Verifies ethical, responsible production practices.

How Can You Assess Manufacturing Capacity and Lead Times?

One critical aspect of a successful partnership is understanding your manufacturer’s capacity and typical lead times. A mismatch here could lead to production delays, impacting your delivery schedules and, ultimately, your business.

Request production capacity details and standard lead times to match your business needs and prevent delays.

Ask manufacturers about their maximum production capacity per month, seasonal demand variations, and lead times for initial and repeat orders. This will give you insight into their ability to scale with your business. It’s also important to discuss any surge capacities and backup plans to ensure timely deliveries, even during peak seasons. Read our article on Managing Production Lead Times to learn more about planning for seasonal fluctuations and mitigating delays.

Claims:

Manufacturers should provide a clear production schedule based on your demands.

Clear communication on lead times reduces unexpected delays.

How Important Is Quality Control and Product Testing?

Quality control is a non-negotiable factor in manufacturing insulated tumblers. Poor quality can not only lead to product returns but can also damage your brand reputation. So how can you be sure that a manufacturer maintains high quality?

Ensure the manufacturer has strict quality control processes, including batch testing, visual inspections, and vacuum sealing tests.

Request to review their quality control checklist, which should include inspections for leakage, insulation performance, and visual flaws. Quality control at the factory reduces the risk of defective products reaching customers. Many reliable manufacturers will also provide sample testing and third-party inspections to guarantee top-tier quality. Explore our Quality Control Checklist for Drinkware Manufacturers for a detailed list of what to look for in a quality control process.

Claims:

Batch testing and inspections ensure every unit meets your standards.

Quality assurance checks minimize defect rates and maintain brand integrity.

What Is the Importance of Communication and Transparency?

Clear and consistent communication is the foundation of a successful manufacturing partnership. Working with a responsive and transparent manufacturer can help avoid misunderstandings and streamline the production process.

Choose a manufacturer that prioritizes open communication, provides regular updates, and shares clear documentation on every stage of production.

A responsive manufacturer should be available to answer questions promptly, update you on production milestones, and provide solutions if issues arise. Transparency in areas like pricing, material sourcing, and order tracking is essential, especially for international partnerships where miscommunication can lead to costly mistakes. If transparency is a priority, our Guide to Building Strong Supplier Relationships outlines key practices to establish open and effective communication with manufacturers.

Claims:

Regular updates help maintain production transparency.

Clear communication channels reduce the risk of errors and delays.

Conclusion: How Do You Make the Final Choice?

In choosing a Chinese insulated steel water tumbler manufacturer, focus on quality standards, production capacity, clear communication, and customization options. Take time to vet manufacturers thoroughly, asking detailed questions and requesting samples when possible. By prioritizing these factors, you can confidently select a manufacturing partner that meets your quality, timeline, and budget needs.

Recommended External Links

ISO 9001 Certification Information