Worried about water safety in your building or business? Stainless steel pipes might be the clean, long-term answer you need.

Stainless steel pipes are widely recognized as a safe, hygienic, and corrosion-resistant option for transporting drinking water.

Keep reading to explore how stainless steel ensures safety, its comparison with other pipe materials, and industry standards that matter.

What Makes Stainless Steel Pipes Suitable for Drinking Water?

Safe plumbing starts with safe materials—and stainless steel fits the bill.

Stainless steel pipes are non-porous, resist bacterial growth, and offer high strength and corrosion resistance, making them ideal for drinking water.

Why They Work

- Non-reactive surface: No harmful chemicals leach into water.

- Smooth interior: Prevents biofilm or bacterial buildup1.

- Durability: Withstands pressure and daily use for decades.

Are Stainless Steel Pipes Chemically Safe and Lead-Free?

You shouldn't have to worry about lead or contamination every time you turn on the tap.

Stainless steel plumbing alloys are lead-free and resist corrosion, thanks to their chromium-rich composition that forms a passive oxide layer2.

Safety Explained

- No lead: Unlike some older metal pipes, stainless steel is free of toxic lead.

- No leaching: Properly manufactured stainless pipes won't release harmful metals.

- Passive protection: Chromium creates a natural protective barrier.

How Do Stainless Steel Pipes Compare to Copper and PVC for Drinking Water?

Wondering which pipe is better for your project?

Stainless steel outperforms copper and PVC3 in corrosion resistance, pressure tolerance, and long-term safety.

Comparison Table

| Feature | Stainless Steel | Copper | PVC |

|---|---|---|---|

| Lead Content | Lead-free | Possible in older pipes | Lead-free |

| Corrosion Resistance | Excellent | Moderate | Good (UV weak) |

| Durability | Very High | Moderate | Moderate |

| Bacterial Growth | Minimal | Moderate risk | Possible |

| Pressure Resistance | Up to 4000 kPa | Lower | Moderate |

| Recyclability | 100% recyclable | Recyclable | Not recyclable |

| Health Risk | None | Metal leaching possible | Chemical residues possible |

What Standards and Certifications Ensure Safety of Stainless Steel Pipes?

It's not just about the material—it's about proof.

Stainless steel pipes certified under standards like NSF/ANSI 614 and made from grades like 304 or 3165 are safe for potable water.

Common Certifications

- NSF/ANSI 61 (USA): Safe for drinking water contact

- EN/DIN/ISO 1124: European water standards

- MoH Italy (1973): Grade 304/316 approved for drinking use

Always confirm the pipe grade and request certification documents from suppliers.

What Are the Key Benefits of Using Stainless Steel Pipes in Water Systems?

Cost-effective? Yes. Safe and sustainable? Absolutely.

Stainless steel pipes offer durability, hygiene, safety, and environmental benefits unmatched by many traditional materials.

Top 5 Advantages

- Corrosion resistance: Prevents rust and contamination.

- Hygienic surface: Non-porous, no biofilm.

- Durable: Often lasts 50+ years.

- Lead-free: Peace of mind for your family or facility.

- Sustainable: 100% recyclable6, minimal waste.

Are There Any Concerns With Stainless Steel Pipes—and How to Address Them?

No system is perfect—but with proper planning, issues can be avoided.

Stainless steel is safe, but improper installation or wrong material pairings can introduce risk.

Watch for:

- Seal/joint materials: Use potable-grade seals to avoid contamination.

- Improper welding: Use clean tools and food-grade welding rods.

- Wrong grade: Use 304 or 316 for drinking water—other grades may corrode.

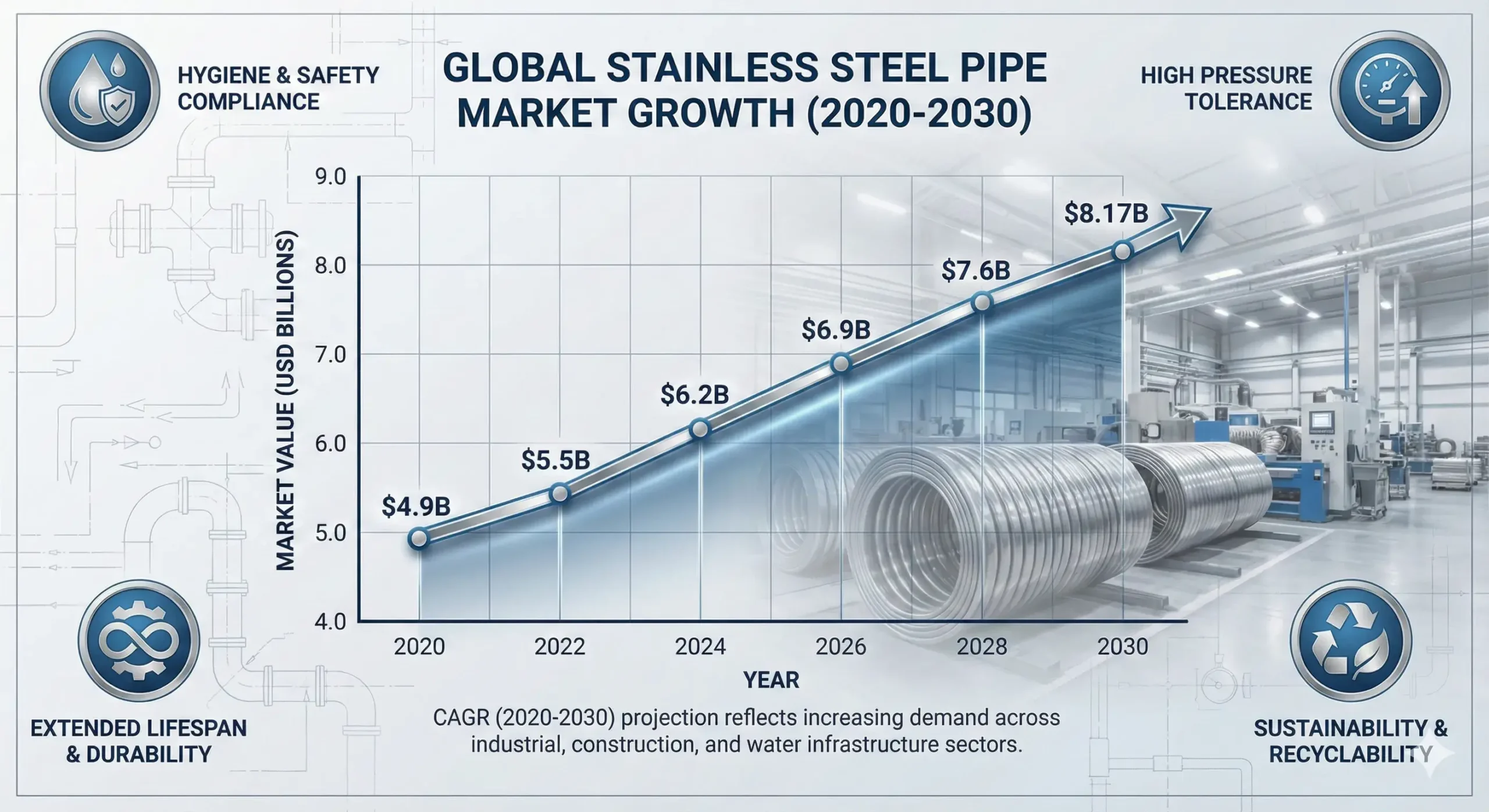

What Do Market Trends Say About Stainless Steel in Potable Water Systems?

Safe water isn't a trend—it's a growing demand.

Global market data shows rising adoption of stainless steel pipes for their hygiene, safety, and lifespan.

Industry Data

| Metric | Value | Year |

|---|---|---|

| Global market size7 | $4.9 billion | 2020 |

| Projected size | $8.17 billion | 2030 |

| CAGR | 4.8% annual growth | 2021–30 |

| Pipe pressure tolerance | Up to 4000 kPa | 2024 |

| Global stainless pipe production | 53 million metric tons | 2026 |

How Long Do Stainless Steel Pipes Last in Drinking Water Applications?

Installing once and not replacing for decades? That's the goal.

With minimal maintenance, stainless steel water pipes can last over 50 years8, reducing long-term costs.

Maintenance Tips

- Inspect joints and seals periodically.

- Clean internally if needed in high-mineral areas.

- Use qualified installers to avoid damage during setup.

Frequently Asked Questions About Stainless Steel Pipes and Drinking Water Safety

Are stainless steel pipes safe for drinking water?

Yes. They are lead-free, corrosion-resistant, and hygienic—making them a safe material for transporting drinking water.

Which stainless steel grade is best for potable water pipes?

Grades 304 and 316 are industry standards for drinking water due to their high corrosion resistance and safety.

Can stainless steel pipes leach metals into drinking water?

No, not when manufactured correctly. The protective oxide layer on stainless steel prevents leaching of harmful metals.

How does stainless steel compare to copper for drinking water?

Stainless steel is stronger, longer-lasting, and less likely to leach metal ions than copper, especially in old systems.

Do stainless steel pipes require special maintenance?

No special treatment is required. Just regular inspection and cleaning of seals or joints to ensure system hygiene.

Conclusion

Stainless steel pipes are one of the safest and most reliable materials for drinking water systems. Their corrosion resistance, durability, and hygienic surface help deliver clean water for decades with minimal maintenance. Backed by international safety standards and favored in both residential and industrial plumbing, they offer a future-proof investment in public health and sustainability. If you're designing or upgrading a water system, stainless steel isn't just a good option—it's the smart one.

-

Allmach explains how stainless steel does not promote biofilm growth, which is essential for bacterial development. The smooth, hard oxide layer makes it difficult for bacteria and microorganisms to colonize, unlike copper which can support biofilm formation in water systems. ↩

-

Industrial Metallurgists provides a scientific explanation of stainless steel's passive layer—a thin (30-50 nanometer) chromium oxide film that forms on the surface. This layer renders the steel electrochemically passive and prevents corrosion in drinking water environments. ↩

-

h2x Engineering cites European Commission research showing stainless steel outperforms copper in preventing emissions from leaching into drinking water. The study found that older copper pipes release higher concentrations of copper ions, which can cause health issues over time. ↩

-

NSF International is the authoritative source for the NSF/ANSI 61 standard, which establishes minimum health-effects requirements for materials in contact with drinking water. This certification is required across most U.S. states and Canadian provinces for potable water system components. ↩

-

Boshart's technical comparison explains that Grade 304 contains 18-20% chromium and 8-12% nickel for general potable water use, while Grade 316 adds 2-3% molybdenum for superior corrosion resistance in high-chloride or coastal water environments. ↩

-

Splitflask explains the environmental benefits of stainless steel, noting that it is fully recyclable without losing quality. Unlike plastic which degrades during recycling, stainless steel can be melted down and reused indefinitely, making it a sustainable choice for water infrastructure. ↩

-

Allied Market Research provides comprehensive industry data showing the global stainless steel plumbing pipes market was valued at $8.17 billion in 2020, with projected growth at 4.8% CAGR through 2030 driven by infrastructure development and renovation activities worldwide. ↩

-

TSINGCO's comprehensive guide on stainless steel pipe longevity explains that properly maintained pipes in water supply systems typically last 70-100 years. Grade 316 pipes can exceed this lifespan under standard conditions, with some installations remaining functional for over a century. ↩