Think stainless steel is rust-proof? Exposure to water can still cause damage if you don't understand its limits.

Stainless steel is water-resistant, not completely waterproof, due to its protective chromium oxide layer that resists moisture and rust.

Learn the difference, how to maintain it, and which stainless steel grades perform best in wet conditions.

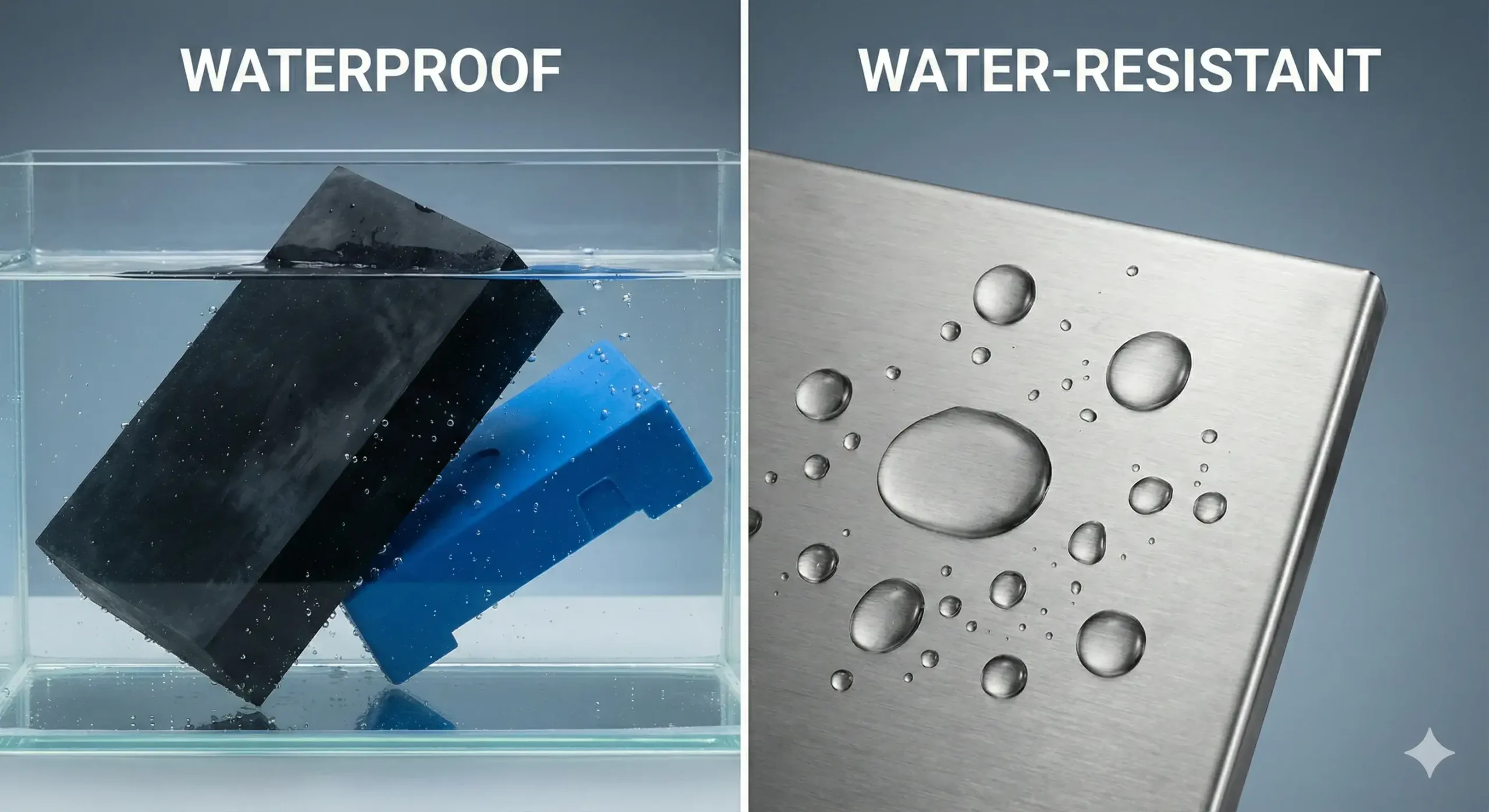

Understanding the Difference: Waterproof vs Water-Resistant?

Not all materials block water the same way. The terms matter.

Waterproof materials block all water under any condition, while water-resistant materials resist water to a significant extent but not fully.

Key Distinction

Stainless steel doesn’t allow water to easily penetrate or cause rust because of its chromium content. But if that surface is damaged or exposed to harsh conditions too long, water may eventually break through. It’s more accurate to call stainless steel water-resistant, not fully waterproof.

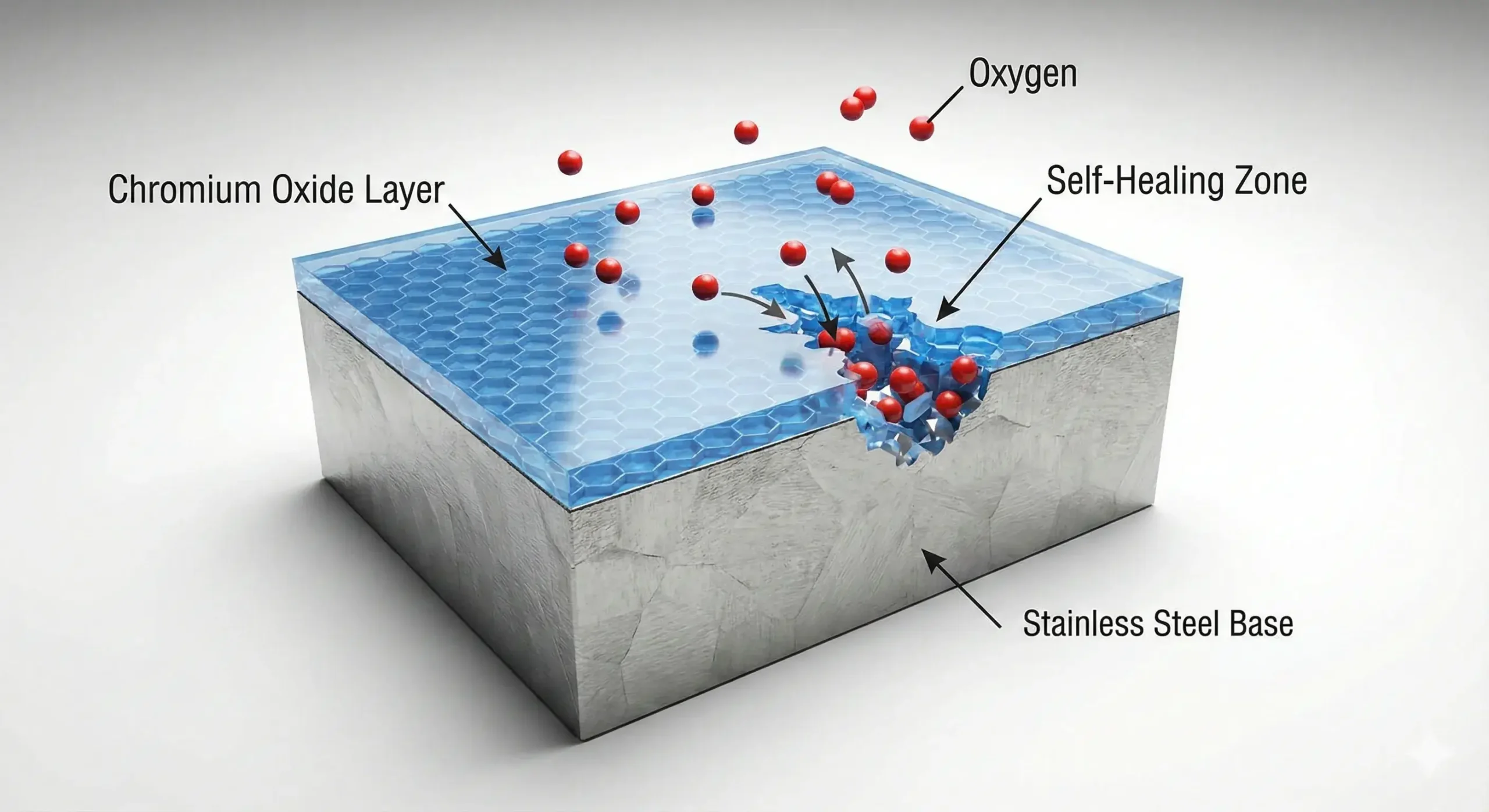

What Makes Stainless Steel Water-Resistant?

Ever wonder how stainless steel stays shiny and rust-free?

The chromium in stainless steel forms a thin, self-healing oxide layer that blocks moisture and oxygen from causing rust.

The Chromium Oxide Shield

- Chromium content ≥10.5%

- Reacts with oxygen to form a stable oxide barrier

- Prevents moisture from reaching the steel beneath

- Self-repairs minor scratches if oxygen is present

This barrier is why stainless steel survives in kitchens, bathrooms, and marine environments longer than many other metals.

Is Stainless Steel Truly Waterproof?

Don't let the shine fool you—it's not indestructible.

Stainless steel can corrode with long-term water or chemical exposure, especially in saltwater or acidic environments.

Real-World Performance

- Prolonged exposure to seawater can break down the oxide layer

- Grades like 316L resist better due to added molybdenum

- Welded or scratched areas are more prone to corrosion

In marine, medical, or chemical uses, higher-grade stainless steel is essential for performance under constant wet conditions.

Which Stainless Steel Grades Are Most Water-Resistant?

Choosing the wrong grade may lead to rust—even with stainless steel.

Grade 316L offers the highest water resistance thanks to its molybdenum content, while 304 performs well in most household uses.

Water Resistance Comparison

| Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Water Resistance Level | Common Use Cases |

|---|---|---|---|---|---|

| 304 | 18–20 | 8–10 | 0 | High | Sinks, cookware, appliances |

| 316 / 316L | 16–18 | 10–14 | 2–3 | Very High | Marine, medical, lab gear |

| 430 | 16–18 | 0 | 0 | Moderate | Automotive, interior décor |

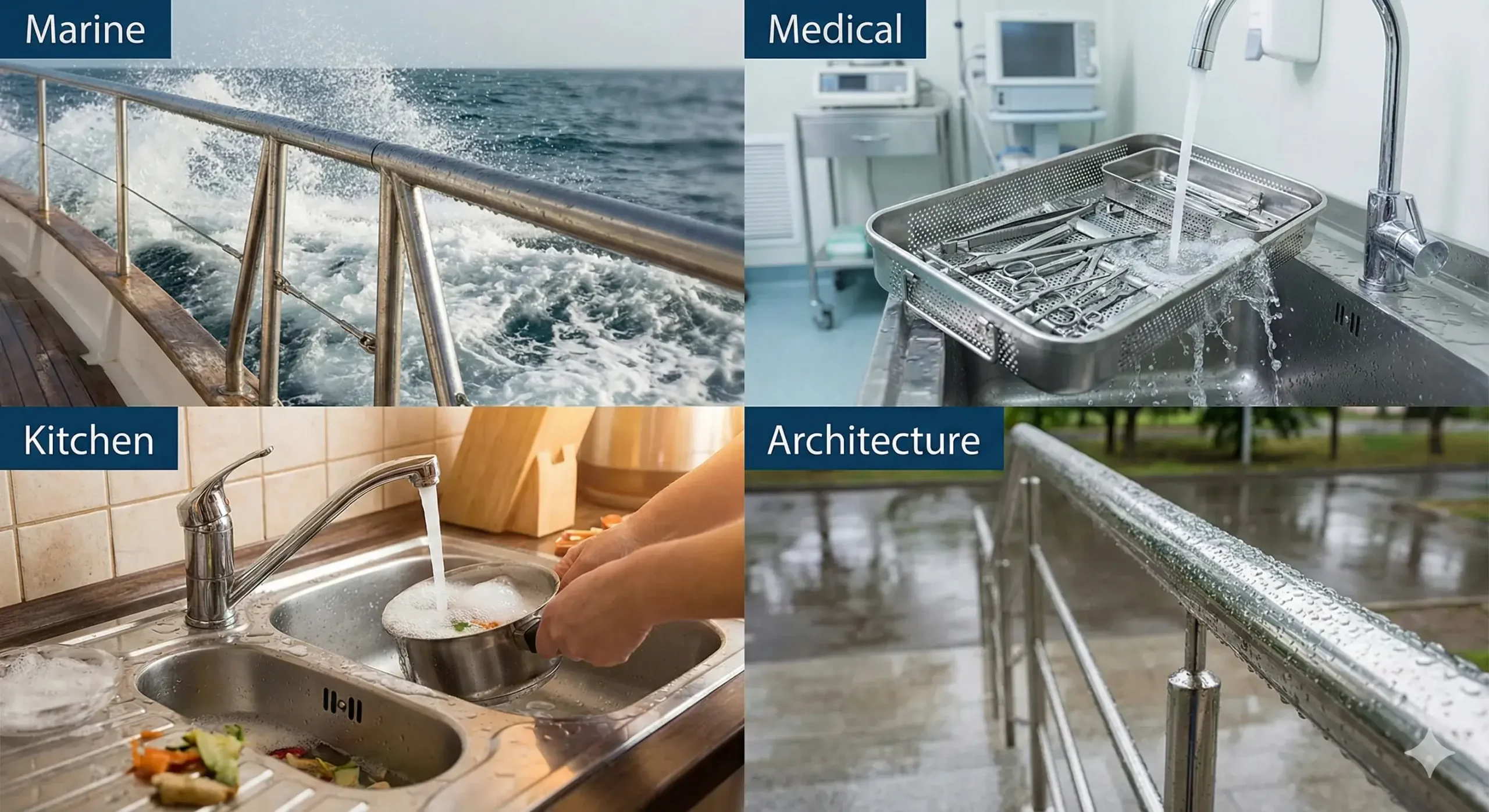

Where Does Stainless Steel’s Water Resistance Matter Most?

It’s not just kitchens—moisture challenges are everywhere.

Stainless steel’s water resistance is crucial in marine, food, architectural, and medical environments.

Real-Life Applications

- Marine Equipment – Boats, docks, and underwater structures

- Medical Tools – Surgical instruments, lab devices

- Architecture – Railings, outdoor fixtures

- Food & Beverage Processing – Pipes, tanks, countertops

- Jewelry and Watches – Daily water exposure, sweat, rain

Without this resistance, equipment would rust, weaken, or fail in wet conditions.

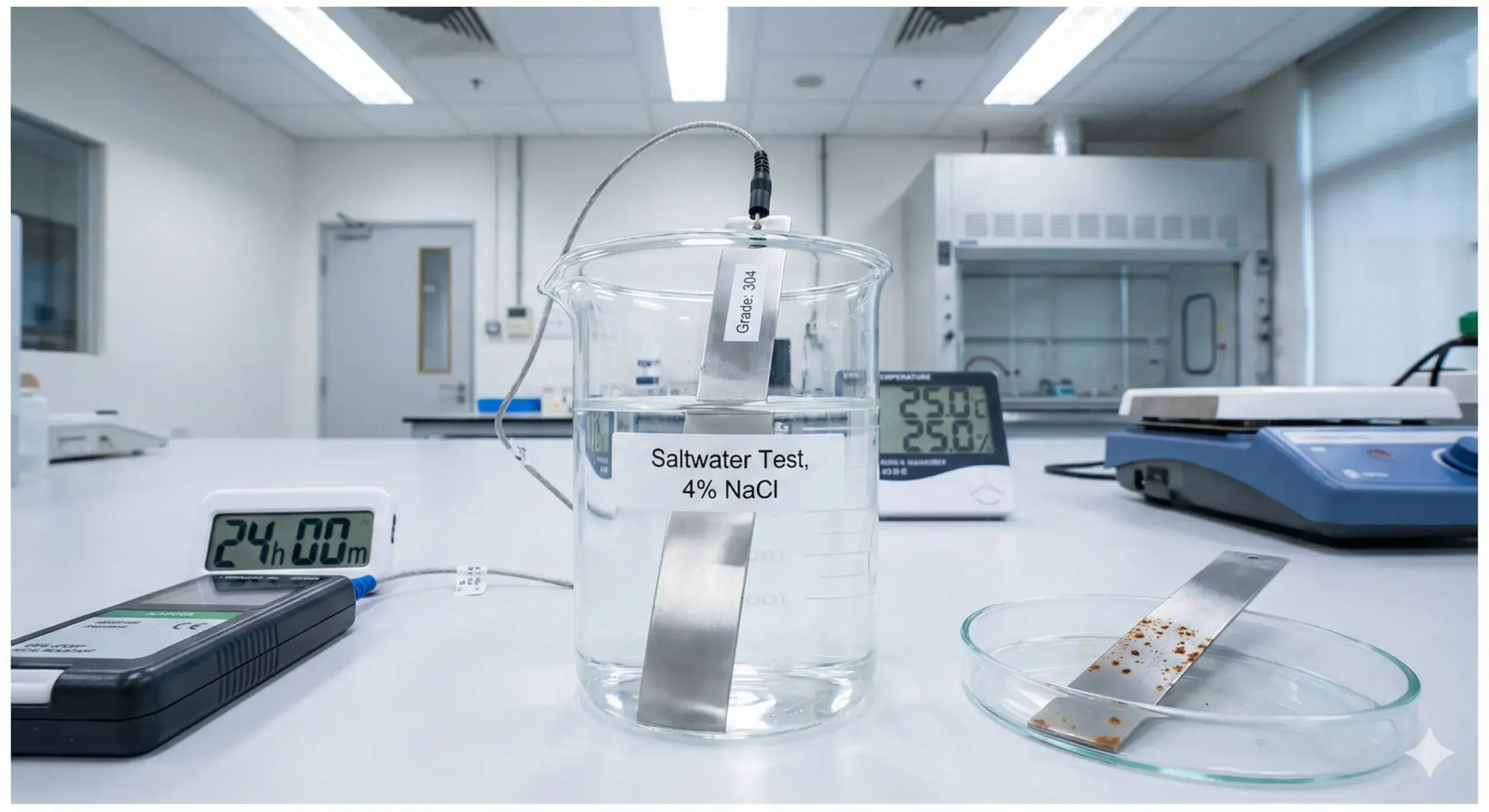

How Is Stainless Steel Tested for Water Resistance?

Lab tests simulate the worst-case scenarios to ensure quality.

Immersion testing places stainless steel in corrosive water or saltwater for days or weeks to observe pitting, rust, or surface breakdown.

Common Testing Conditions

- Submersion in 4% saline or acetic acid

- Exposure to varying temperatures

- Observing changes over time (24h–30 days)

- Evaluation of pitting, discoloration, rust

Results help manufacturers choose the right grade and ensure quality for each application.

How Do You Maintain Stainless Steel’s Water Resistance?

Even stainless steel needs care to stay rust-free.

Clean regularly, rinse after saltwater exposure, and avoid chemicals that strip the protective oxide layer.

Maintenance Checklist

- ✅ Wash with mild detergent and soft cloths

- ✅ Dry thoroughly after rinsing

- ✅ Avoid bleach and strong acids

- ✅ Use the right grade for your environment

- ✅ Polish lightly if discoloration occurs

With care, stainless steel can last decades—even in wet environments.

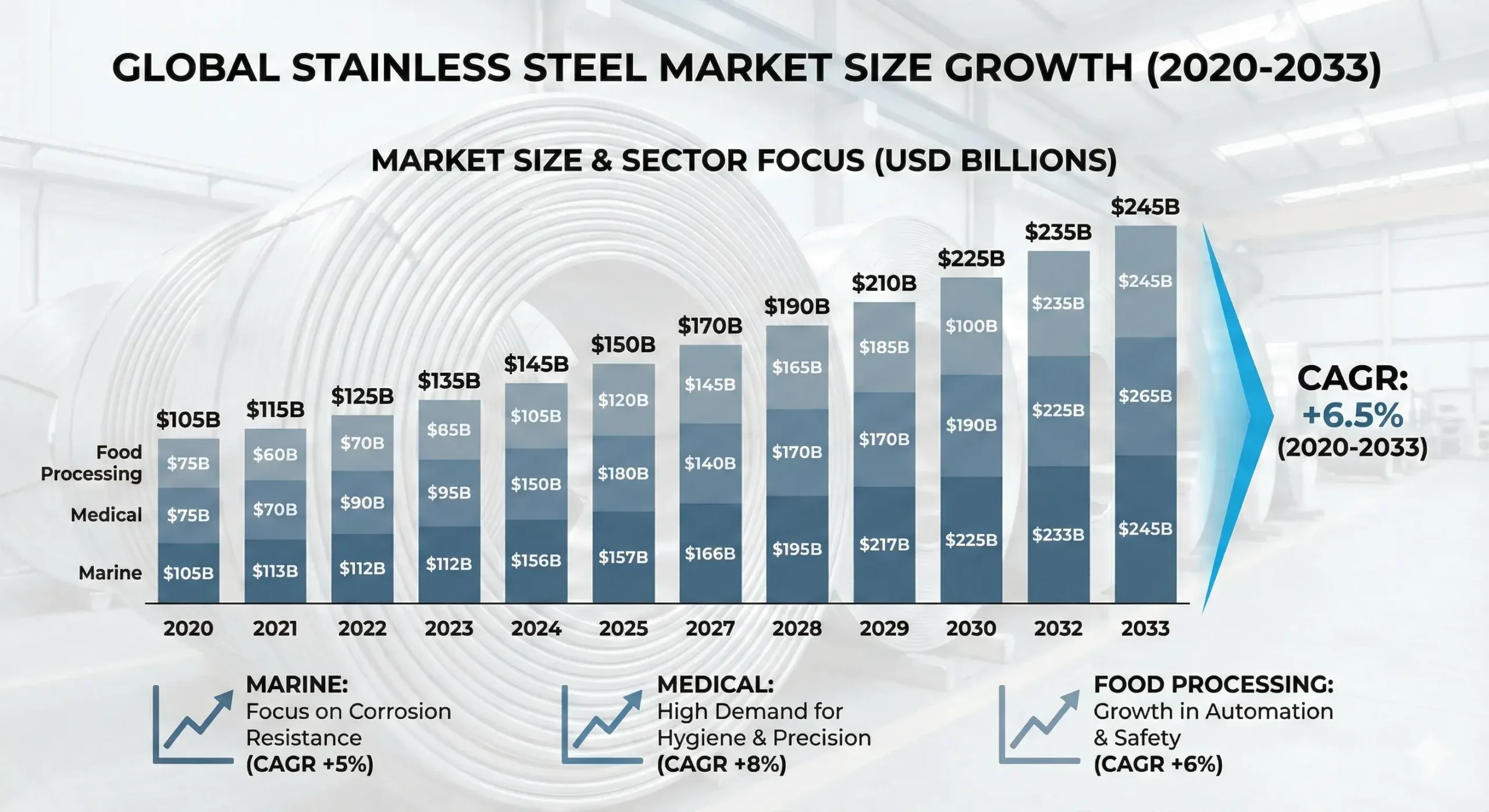

Market Trends: Stainless Steel in Wet Environments

The world is getting wetter—and smarter about materials.

Demand for corrosion-resistant stainless steel is growing, especially in marine, chemical, and food industries.

Key Stats

| Statistic / Trend | Data / Insight | Year |

|---|---|---|

| Global stainless steel market value | Approx. USD 12.5 billion | 2024 |

| Projected CAGR (2024–2033) | 5.7% growth | 2024–2033 |

| Global stainless steel output | 53+ million metric tons | 2026 |

| Top growth sectors | Marine, chemical, architectural use | 2024 |

Companies are investing more in high-grade stainless steel to extend product life and lower maintenance costs.

Conclusion

Stainless steel is water-resistant, not fully waterproof. But with the right grade and care, it can handle tough wet conditions safely and effectively.

FAQs

Is stainless steel waterproof or just water-resistant?

Stainless steel is water-resistant. It can handle moisture well but may corrode over time in harsh conditions.

Can stainless steel rust if exposed to water?

Yes. If the chromium oxide layer is damaged or the steel is exposed to salt or acids for too long, it can rust.

Which stainless steel grade is best for water exposure?

316 or 316L is best. They contain molybdenum for better corrosion resistance in wet or marine environments.

Can I wear stainless steel jewelry in the shower or pool?

Yes. Most stainless steel jewelry is safe for showering or swimming, but over time, salt and chlorine can cause wear.

How do you maintain stainless steel’s water resistance?

Clean regularly, rinse after salt exposure, avoid harsh cleaners, and fix surface scratches to keep the oxide layer intact.