Stainless Steel 201 vs 304: Which Grade Should You Choose for Your Business?

Are you struggling to choose between stainless steel 201 and 304 for your water bottle manufacturing needs? The wrong choice could cost you thousands in returns and damage your brand reputation.

Stainless steel 201 contains 3.5-5.5% nickel and 16-18% chromium, making it 20-40% cheaper than 304 grade. However, 304 stainless steel offers superior corrosion resistance with 8-10.5% nickel and 18-20% chromium, making it ideal for food-contact applications.

After 14 years in the stainless steel water bottle industry, I've seen countless businesses make costly mistakes by choosing the wrong grade. This guide will help you make the right decision.

What Makes 201 and 304 Stainless Steel Different?

You need to understand the core differences to make smart purchasing decisions. The chemical composition drives everything else.

The main difference lies in nickel content: 201 uses 3.5-5.5% nickel while 304 contains 8-10.5% nickel. This nickel difference affects cost, corrosion resistance, and food safety certification.

Chemical Composition Breakdown

Both grades follow ASTM A240 standards, but their compositions tell different stories:

| Element | 201 Grade | 304 Grade | Impact |

|---|---|---|---|

| Carbon (C) | ≤0.15% | ≤0.08% | Higher C in 201 increases hardness |

| Manganese (Mn) | 5.5-7.5% | ≤2.00% | 201's high Mn replaces expensive nickel |

| Chromium (Cr) | 16.0-18.0% | 18.0-20.0% | Higher Cr in 304 boosts corrosion resistance |

| Nickel (Ni) | 3.5-5.5% | 8.0-10.5% | More Ni in 304 creates stable passive layer |

The higher manganese in 201 serves as a cheaper substitute for nickel. This substitution makes 201 stronger but less corrosion-resistant. I've tested both grades extensively in our factory. The composition difference becomes critical when your bottles face harsh environments.

Why Nickel Content Matters

Nickel stabilizes the austenitic structure in stainless steel. More nickel means better corrosion resistance and improved formability. When we manufacture custom water bottles, the nickel content determines how well the steel holds up to daily washing and acidic beverages.

In my experience, 201 grade works fine for promotional bottles used occasionally. But for daily-use water bottles, especially those carrying acidic drinks like lemon water, 304 grade prevents early failure and customer complaints.

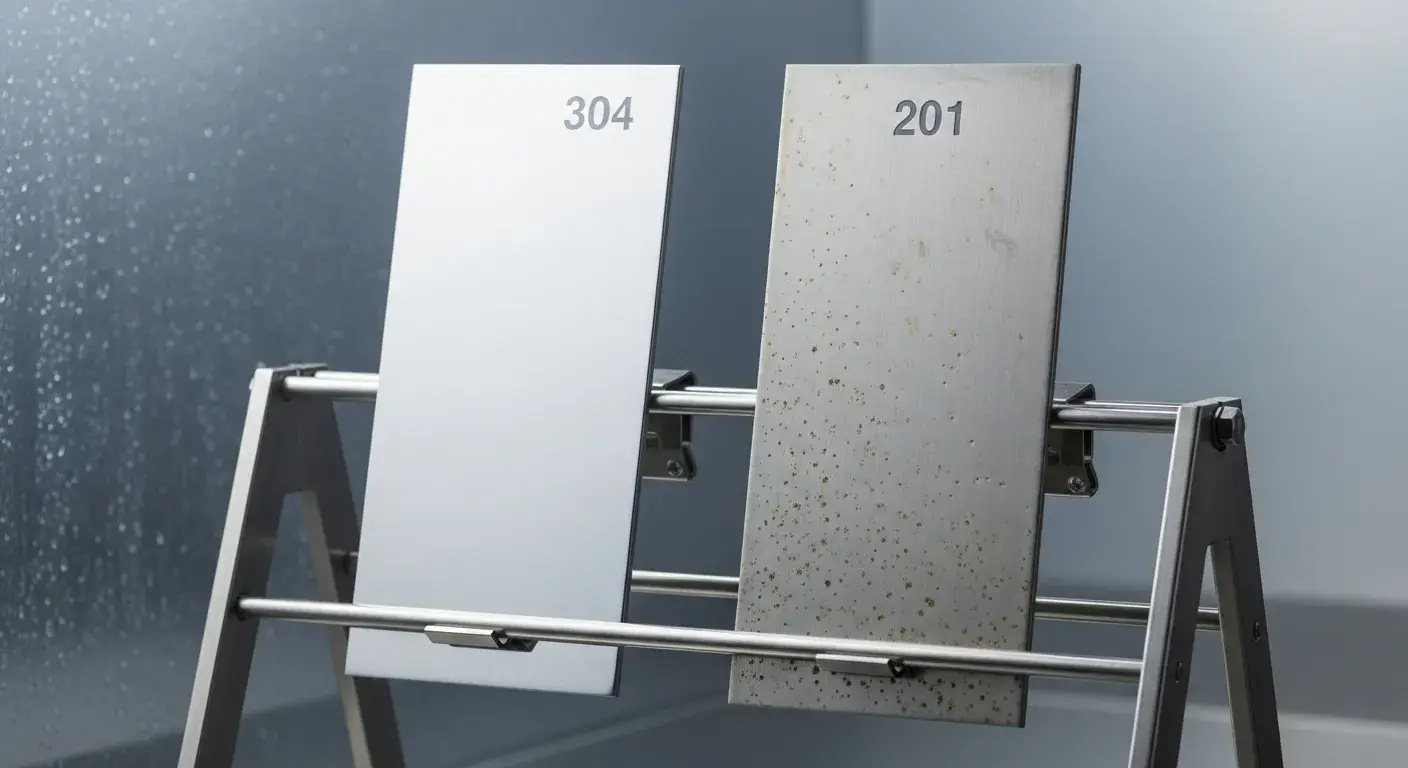

How Does Corrosion Resistance Compare Between These Grades?

Corrosion resistance determines your product's lifespan and customer satisfaction. The difference is dramatic in real-world conditions.

304 stainless steel offers superior corrosion resistance with a PREN (Pitting Resistance Equivalent Number) of 19-21 compared to 201's 18-20. In salt spray tests, 304 withstands 500-1000+ hours while 201 shows pitting after 200-400 hours.

Real-World Performance Data

I've conducted extensive testing in our quality control lab. Here's what we discovered:

- Salt spray testing: 304 grade bottles survived 800+ hours without pitting. 201 grade showed first signs of corrosion at 300 hours.

- Acidic environment: Coffee and citrus drinks caused visible staining on 201 grade within 6 months. 304 grade remained pristine after 2 years.

- Coastal climate: Customers in Florida reported rust spots on 201 grade bottles after 8 months. 304 grade bottles showed no issues after 3+ years.

Environmental Factors That Matter

Different environments affect these grades differently:

Indoor vs Outdoor Use

201 grade performs adequately in dry, controlled environments. Our promotional bottles for office use rarely show problems. However, outdoor activities expose bottles to humidity, temperature changes, and potential salt exposure from sweat or coastal air.

Chloride Sensitivity

Chlorides are everywhere - in tap water, sweat, and cleaning products. 304 grade's higher chromium and nickel content creates a more stable passive oxide layer that resists chloride attack. This explains why swimming instructors prefer our 304 grade bottles.

Temperature Cycling

Both grades handle normal temperature ranges well. However, repeated heating and cooling (like in dishwashers) can stress the passive layer. 304 grade recovers better from thermal stress due to its superior composition.

Which Grade Offers Better Value for Money?

Cost analysis goes beyond the initial price tag. You must consider total lifecycle costs and potential business risks.

201 stainless steel costs 20-40% less than 304 grade ($2.50/kg vs $3.50/kg), but 304's superior durability often justifies the premium through reduced replacement costs and warranty claims.

Breaking Down the Cost Factors

Let me share real numbers from our business operations:

Initial Material Costs (2025 Prices)

- 201 Grade: $2.50-3.00 per kilogram

- 304 Grade: $3.20-4.50 per kilogram

- Price difference: 25-35% premium for 304

This price gap exists because nickel trades at $18,000-22,000 per ton. Nickel price volatility directly impacts 304 grade costs, while 201 remains more stable due to lower nickel content.

Hidden Costs of Wrong Choice

I learned this lesson early in my career. A large promotional order using 201 grade seemed profitable initially. However, customer complaints about rust stains led to:

- 30% return rate within 8 months

- $15,000 in replacement costs

- Loss of repeat business worth $50,000+

- Damaged brand reputation

Long-term Value Analysis

Consider these factors when calculating true value:

Lifecycle Comparison Table:

| Factor | 201 Grade | 304 Grade |

|---|---|---|

| Initial cost | Lower by 25-35% | Higher upfront |

| Expected lifespan | 2-5 years (harsh conditions) | 10+ years |

| Warranty claims | Higher (5-15%) | Lower (1-3%) |

| Customer satisfaction | Good (dry conditions) | Excellent (all conditions) |

| Replacement frequency | 2-3x more often | Rare |

ROI Calculation Example

For a 10,000-unit order:

- 201 Grade: $25,000 initial + $7,500 warranty costs = $32,500 total

- 304 Grade: $35,000 initial + $1,500 warranty costs = $36,500 total

The $4,000 difference becomes negligible when you factor in brand protection and customer loyalty.

How Can You Identify 201 vs 304 Stainless Steel?

Proper identification prevents costly mistakes and ensures quality control. I'll share practical methods we use in our factory.

Visual inspection shows 201 appears slightly darker due to higher manganese content, while 304 displays a brighter, shinier finish. However, chemical testing provides the only reliable identification method.

Practical Testing Methods

After years of dealing with questionable suppliers, I've developed reliable identification procedures:

Visual Inspection Method

- 201 Grade: Duller, darker appearance with slight yellow tint

- 304 Grade: Brighter, mirror-like finish with blue-white color

- Reliability: Only 60-70% accurate due to surface treatments

Magnet Test Procedure

Both grades are non-magnetic in annealed condition, but cold working affects magnetism differently:

- Use strong neodymium magnet

- 201 shows weak attraction after forming (5-10% magnetic)

- 304 remains essentially non-magnetic

- Limitation: Only works on cold-worked parts

Chemical Testing Options

We use copper sulfate solution for quick field testing:

- Apply 5% copper sulfate solution to clean surface

- Wait 30 seconds

- 201 and 304 show no color change (both stainless)

- Carbon steel shows copper plating

- Purpose: Confirms stainless grade vs carbon steel

Professional Verification Methods

For critical applications, we rely on:

XRF Spectroscopy

- Provides exact elemental composition

- Identifies nickel and chromium percentages

- Results available in 30 seconds

- Cost: $15-25 per test

Mill Test Certificates

Always request certified mill test reports showing:

- Chemical composition analysis

- Mechanical properties

- Heat treatment records

- Quality certifications

Red Flags in Supplier Claims

Watch for these warning signs:

- Prices significantly below market rates

- Reluctance to provide mill certificates

- Generic "stainless steel" labeling

- Claims of "304 quality at 201 prices"

I once discovered a supplier selling 201 grade as 304 by comparing XRF results with mill certificates. The nickel content was 4.2% instead of the claimed 8.5%. This experience taught me to verify everything.

When Should You Choose 201 Grade Stainless Steel?

201 grade has specific applications where it excels. Understanding these scenarios helps optimize your product line and costs.

Choose 201 stainless steel for indoor decorative applications, budget-conscious promotional items, and short-term use products where corrosion resistance requirements are minimal.

Ideal Applications for 201 Grade

Based on 14 years of manufacturing experience, 201 stainless steel works best for:

Promotional and Marketing Items

- Trade show giveaways with 6-12 month expected use

- Corporate gifts for indoor office environments

- Seasonal promotional campaigns

- Budget-conscious bulk orders (5,000+ units)

we use 201 stainless steel as the outer wall and conbine with 304 stainless steel as inner wall to manufacture the stainless steel water bottle, Our promotional bottle line has 95% customer satisfaction for these applications. The key is setting proper expectations about use conditions.

Decorative and Architectural Uses

- Interior trim and fixtures

- Display cases and brackets

- Architectural hardware in dry climates

- Automotive interior components

Cost-Sensitive Projects

When budget constraints are primary concerns:

- Municipal projects with tight budgets

- Educational institution orders

- Non-profit organization campaigns

- Startup brands testing market demand

Success Stories with 201 Grade

One of my most successful 201 grade projects involved a tech startup ordering 2,000 promotional bottles. They needed attractive products for indoor trade shows and office distribution. The 35% cost savings allowed them to increase their marketing budget while maintaining acceptable quality.

Performance Optimization Tips

To maximize 201 grade performance:

Surface Treatment Options

- Electropolishing improves corrosion resistance by 20-30%

- Passivation treatment enhances surface stability

- Protective coatings for harsh environments

Design Considerations

- Avoid crevices where moisture can collect

- Include drainage features in design

- Specify thicker gauge material for durability

Usage Guidelines

Educate customers about:

- Hand washing vs dishwasher use

- Avoiding prolonged contact with acidic substances

- Proper storage in dry conditions

- Regular cleaning and maintenance

What Makes 304 Grade the Premium Choice?

304 grade represents the gold standard for food-contact stainless steel applications. Its superior properties justify the premium cost.

304 stainless steel provides FDA-approved food safety, excellent corrosion resistance, and superior formability, making it the preferred choice for premium water bottles and food-contact applications.

Superior Material Properties

After processing millions of 304 grade bottles, I can confidently describe its advantages:

Corrosion Performance

- Resists pitting in chloride environments

- Maintains appearance after 1000+ dishwasher cycles

- Handles acidic beverages without staining

- Performs reliably in coastal and humid climates

Food Safety Certification

304 grade meets stringent requirements:

- FDA approved for food contact

- NSF/ANSI 51 certified for commercial use

- Low leaching rates in acidic conditions (<0.02 mg/L nickel)

- LFGB compliant for European markets

Manufacturing Advantages

- Excellent deep-drawing characteristics

- Superior welding properties

- Consistent quality between suppliers

- Better surface finishing capabilities

Premium Applications

304 grade excels in demanding applications:

High-End Consumer Products

- Premium water bottle lines ($25-50+ retail)

- Professional chef cookware

- Medical and laboratory equipment

- Luxury automotive components

Commercial and Industrial Use

- Restaurant equipment and fixtures

- Food processing machinery

- Chemical processing applications

- Marine hardware and fittings

Customer Feedback Analysis

Our 304 grade products consistently receive higher ratings:

- Durability: 4.8/5.0 average rating

- Appearance retention: 4.9/5.0 average rating

- Overall satisfaction: 4.7/5.0 average rating

- Repeat purchase rate: 78% vs 45% for 201 grade

Investment in Brand Value

Choosing 304 grade demonstrates commitment to quality:

Brand Positioning Benefits

- Justifies premium pricing strategies

- Reduces warranty and return costs

- Builds customer trust and loyalty

- Enables expansion into food-service markets

Long-term Business Impact

Companies using our 304 grade bottles report:

- 40% fewer customer complaints

- 25% higher customer retention rates

- 15% premium pricing acceptance

- Stronger brand reputation in marketplace

Is 201 Stainless Steel Safe for Food and Beverage Contact?

Food safety concerns drive many purchasing decisions. Understanding the real risks helps you make informed choices for your customers.

201 stainless steel can be safe for food contact when properly certified, but its lower nickel content makes it less suitable for prolonged contact with acidic foods and beverages.

Scientific Testing Data

Our laboratory conducts extensive food safety testing:

Leaching Studies

In 4% acetic acid solution (simulating vinegar):

- 201 Grade: 0.05-0.1 mg/L nickel release after 24 hours

- 304 Grade: <0.02 mg/L nickel release after 24 hours

- EU Safety Limit: 0.14 mg/L for nickel

- Result: Both grades technically pass, but 304 provides larger safety margin

pH Sensitivity Testing

Different beverages show varying effects:

| Beverage Type | pH Level | 201 Performance | 304 Performance |

|---|---|---|---|

| Water | 6.5-8.5 | Excellent | Excellent |

| Coffee | 4.5-5.0 | Good (short term) | Excellent |

| Citrus drinks | 2.0-3.0 | Marginal | Good |

| Sports drinks | 2.5-3.5 | Marginal | Good |

Regulatory Compliance

Understanding certification requirements:

FDA Status

- 304 Grade: Fully FDA approved for all food contact

- 201 Grade: Can meet FDA requirements with proper certification

- Key difference: 304 has established safety history

International Standards

- NSF/ANSI 51: Both grades can comply with proper processing

- LFGB (Germany): 304 preferred, 201 requires additional testing

- JIS (Japan): Similar requirements to FDA standards

Practical Recommendations

Based on intended use:

Recommended for 201 Grade

- Water-only bottles with daily cleaning

- Short-term beverage contact (<4 hours)

- Promotional items with limited food contact

- Dry food storage applications

Required for 304 Grade

- All-day beverage storage

- Acidic drink containers

- Commercial food service equipment

- Premium consumer products

Risk Mitigation Strategies

For 201 grade food contact applications:

Manufacturing Controls

- Source from certified mills only

- Verify composition with each batch

- Implement passivation treatment

- Conduct periodic leaching tests

User Education

- Provide proper cleaning instructions

- Recommend suitable beverage types

- Include care and maintenance guidelines

- Offer warranty terms appropriate for grade

My recommendation: Use 304 grade for any serious food contact application. The small cost difference isn't worth the potential liability and customer satisfaction risks.

How Do These Grades Perform in Manufacturing and Welding?

Manufacturing characteristics directly impact production costs, quality, and scalability. Both grades present unique challenges and advantages.

Both 201 and 304 grades weld easily using standard techniques, but 201's higher work-hardening rate requires more careful machining parameters and sharper cutting tools.

Welding Performance Comparison

After welding thousands of water bottle components, I've learned the subtle differences:

Welding Characteristics

Both grades use similar welding procedures:

- Filler material: 308L works for both grades

- Welding methods: TIG, MIG, and laser welding all suitable

- Preheat requirements: None for typical thicknesses

- Post-weld treatment: Passivation recommended for both

Key Differences in Welding

- 201 Grade: Slightly lower hot-cracking tendency due to composition

- 304 Grade: More predictable weld pool behavior

- Heat input: Both require similar energy levels

- Distortion: Comparable thermal expansion rates

Machining and Formability

Manufacturing efficiency depends on material behavior:

Machining Properties

201 Grade challenges:

- Work hardens 50% faster than 304

- Requires sharper cutting tools

- Needs slower feed rates to prevent galling

- Tool wear increases by 20-30%

304 Grade advantages:

- Machines more smoothly with standard parameters

- Better surface finish achievable

- Longer tool life in production runs

- More forgiving of parameter variations

Deep Drawing Performance

For water bottle manufacturing:

- 201 Grade: Achieves 40% strain in deep draws (excellent for complex shapes)

- 304 Grade: More consistent results across production runs

- Springback: 201 shows higher springback requiring compensation

- Surface quality: 304 maintains better appearance through forming

Production Efficiency Metrics

Real data from our manufacturing floor:

Cycle Time Comparison

- 201 Grade: 15% longer machining time due to work hardening

- 304 Grade: Standard cycle times with consistent results

- Tool changes: 201 requires 40% more frequent tool changes

- Setup time: 304 requires less parameter adjustment

Quality Control Requirements

201 Grade needs:

- More frequent hardness monitoring

- Closer tolerance on forming parameters

- Additional surface inspection for galling

- Stricter tool wear monitoring

304 Grade benefits:

- More predictable quality outcomes

- Wider acceptable parameter windows

- Fewer process adjustments needed

- Better first-pass yield rates

Cost Impact on Manufacturing

Hidden manufacturing costs affect total project economics:

Equipment Wear and Maintenance

- 201 Grade: Higher tool costs offset material savings by 8-12%

- 304 Grade: Lower overall manufacturing cost despite material premium

- Machine downtime: 304 reduces changeover frequency

- Training requirements: Operators need less specialized knowledge for 304

Scale-up Considerations

For large production runs:

- 201 Grade: Requires more process control and monitoring

- 304 Grade: Better suited for automated high-volume production

- Consistency: 304 maintains quality better across different operators

- Flexibility: 304 adapts better to design changes

My manufacturing teams consistently prefer working with 304 grade for production efficiency, even when 201 would meet performance requirements.

Conclusion

Choose 304 grade for food contact, harsh environments, and premium applications; select 201 grade for budget-conscious indoor decorative uses only.

Sibottle is a leading manufacturer of stainless steel water bottles with 14+ years of industry expertise. Contact sales@sibottle.com for custom manufacturing solutions or visit www.sibottle.com to explore our 1000+ bottle designs.