Modern stainless steel water bottle manufacturing facility showcasing advanced production lines

The stainless steel water bottle market is experiencing unprecedented growth, and I've witnessed firsthand how Chinese manufacturers are leading this revolution.

With over a decade of experience in this industry, I've seen the market evolve from simple containers to sophisticated hydration solutions.

Quick Reference: Top Manufacturers Comparison Table

| Manufacturer | MOQ | Lead Time | Specialty | Key Certifications |

|---|---|---|---|---|

| Haers | 3,000 pcs | 25-30 days | Smart Technology | ISO, FDA |

| GINT | 5,000 pcs | 20-25 days | High Volume | ISO |

| Everich | 1,000 pcs | 15-20 days | Sustainability | RCS, GRS |

| Sibottle | 1,000 pcs | 20-25 days | Large Volume & Competitive Price | ISO9001, BSCI |

| KingStar | 2,000 pcs | 25-30 days | Premium Design | Not specified |

| Koodee | 1,000 pcs | 20-25 days | Sports Bottles | SGS, CE |

| LaiKoe | 1,500 pcs | 20-25 days | One-Stop Solutions | Not specified |

| Diller | 1,000 pcs | 15-20 days | OEM/ODM Focus | Not specified |

| Auland | 2,000 pcs | 20-25 days | Automated Production | Not specified |

| Ecoway | 100-3,000 pcs | 15-20 days | Flexible MOQ | ISO, SGS |

Based on industry research and manufacturer specifications as of 2025

Why Smart Buyers Choose Chinese Manufacturers in 2025

China's dominance in stainless steel water bottle manufacturing isn't accidental. Through my extensive work with global brands, I've seen how Chinese manufacturers consistently deliver quality, innovation, and cost-effectiveness that's hard to match elsewhere.

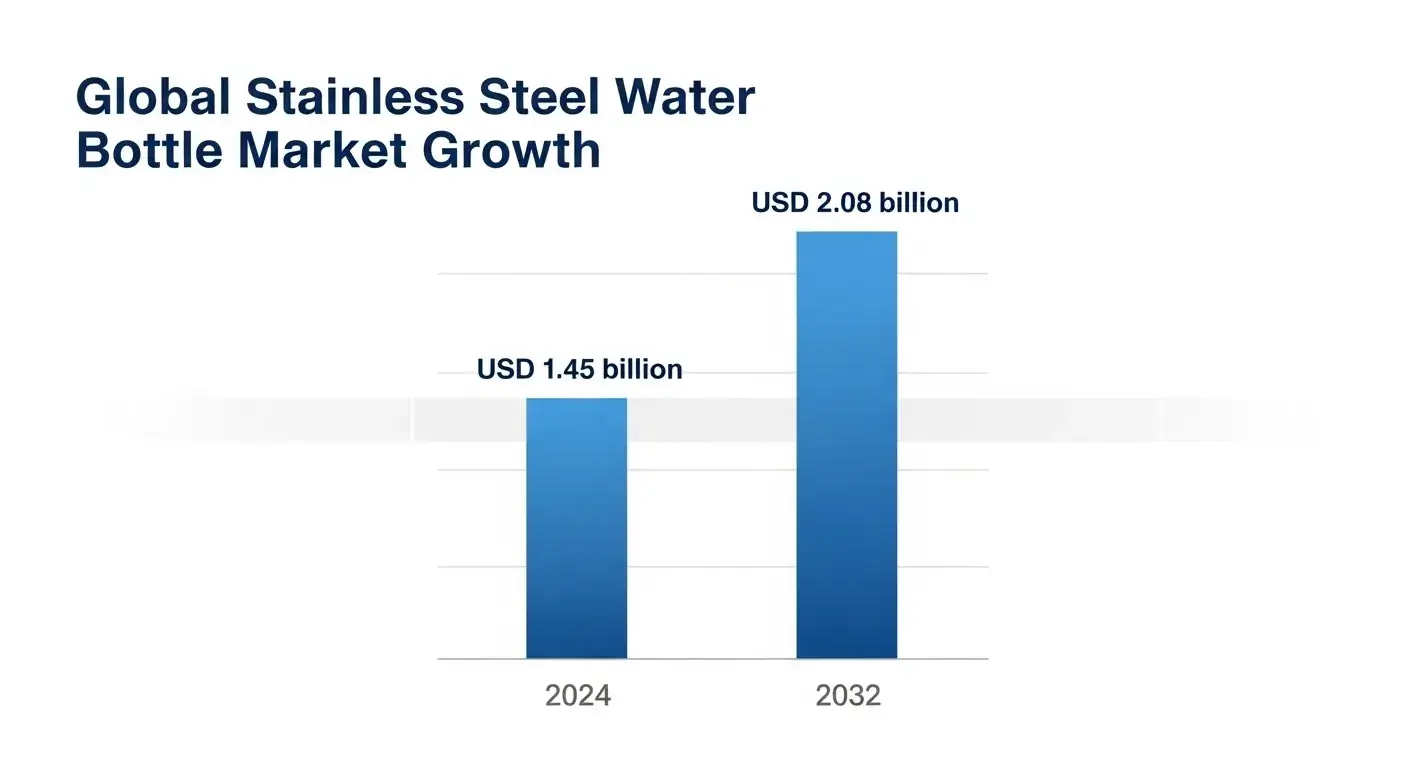

The numbers speak for themselves: the global stainless steel water bottle market reached USD 1.45 billion in 2024 and is projected to hit USD 2.08 billion by 2032, growing at a 4.6% CAGR according to Data Bridge Market Research. China controls approximately 56% of global stainless steel production, making it the natural hub for this industry.

Graph showing the growth trajectory of the global stainless steel water bottle market from 2024 to 2032

What makes Chinese manufacturers particularly attractive for 2025 is their adaptation to emerging trends. From my observations, successful buyers are those who understand these key advantages:

- Advanced Infrastructure: State-of-the-art production facilities with automated assembly lines

- Cost Efficiency: Competitive pricing without compromising quality standards

- Innovation Hub: Leading developments in smart bottles and sustainable materials

- Supply Chain Excellence: Robust logistics networks ensuring timely deliveries

- Customization Capabilities: Extensive design flexibility for brand differentiation

The Asia Pacific region, led by China, is expected to show the fastest growth due to increasing urbanization and rising demand for sustainable products, according to Spherical Insights.

Essential Criteria for Selecting Your Manufacturing Partner

After working with hundreds of buyers over the years, I've identified the critical factors that separate successful partnerships from disappointing experiences. Here's what truly matters when evaluating a stainless steel water bottle manufacturer:

Production Capacity Requirements

Your manufacturer must handle your current volume while scaling for future growth. I've seen too many businesses outgrow their suppliers, causing costly disruptions.

Certification Must-Haves

Never compromise on these essential certifications:

- FDA approval for US market entry

- LFGB certification for European compliance

- ISO 9001 for quality management systems

- BSCI audit for social compliance

MOQ Considerations for Different Business Sizes

- Small businesses: Look for 1,000-2,000 piece minimums

- Medium enterprises: 2,000-5,000 pieces offer better pricing

- Large corporations: 10,000+ pieces unlock maximum cost benefits

Lead Time Expectations

Standard lead times range from 15-30 days, but factors like customization complexity and seasonal demand affect scheduling. Always build buffer time into your planning.

Complete Manufacturer Profiles & Analysis

Tier 1 - Established Industry Leaders

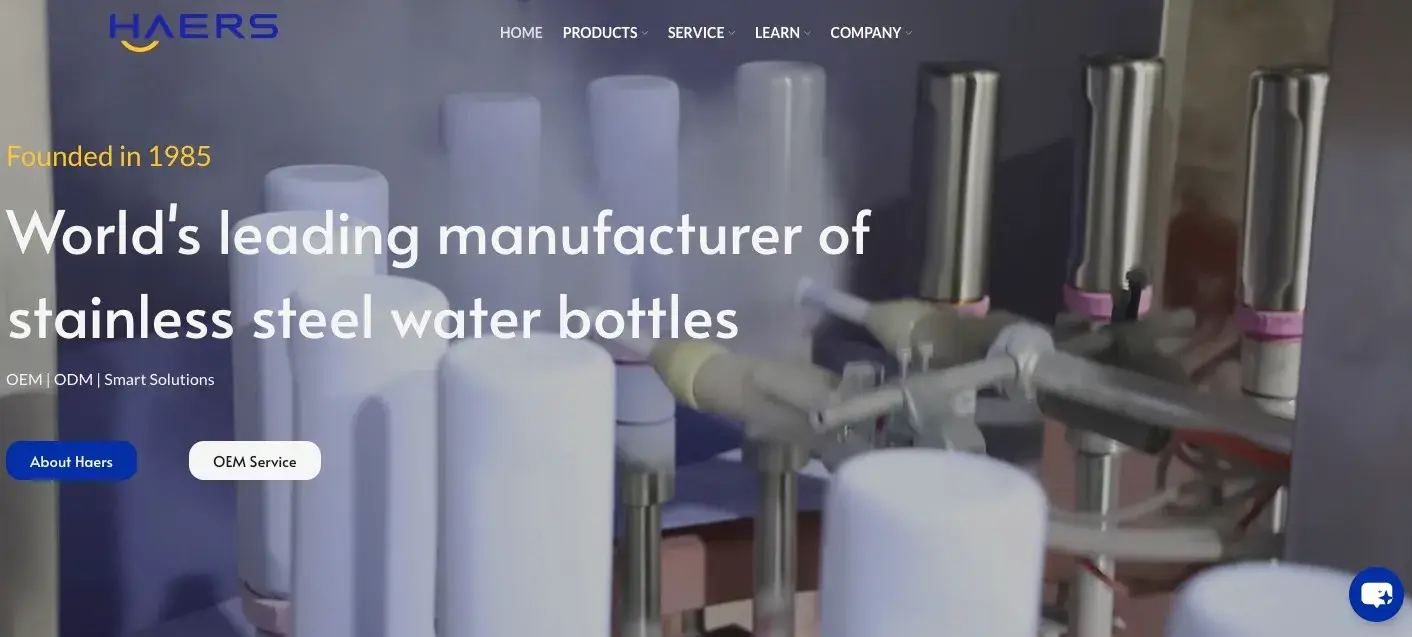

1. Haers - Smart Technology Pioneer

Haers smart water bottle with temperature display and hydration tracking features

Established: 1985 | Location: Yongkang, Zhejiang | Certifications: ISO, FDA

Haers stands out as the self-proclaimed world's largest stainless steel water bottle manufacturer, and from my industry observations, they have the credentials to back this claim. Their recent USD 300 million investment in Smart Manufacturing Park demonstrates serious commitment to innovation.

Key Strengths:

- Smart technology integration (hydration tracking, temperature displays)

- Lead-free materials across all product lines

- Sustainability focus with 2,048 solar panels

- Multiple production bases (China, Thailand, Switzerland)

Best For: Brands seeking cutting-edge smart bottle technology and premium positioning

Learn more about smart bottle trends in our complete guide to stainless steel water bottle manufacturing.

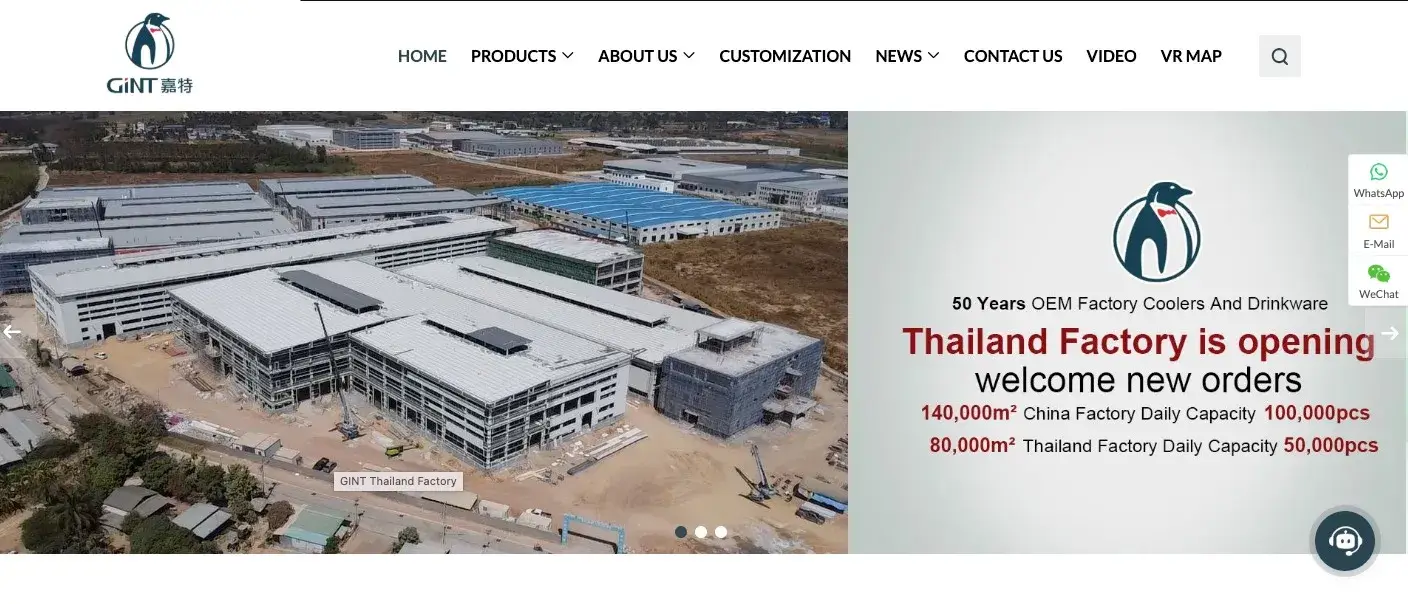

2. GINT - 50+ Years Experience

Established: 1973 | Factory Size: 140,000 sqm | Production: 15 million pieces/year

With over five decades in the business, GINT brings unmatched experience to the table. Their 200+ patents and export to 100+ countries showcase their innovation and global reach.

Key Strengths:

- Longest industry experience (50+ years)

- Robust R&D capabilities

- Sustainable practices (solar panels, waste treatment)

- Extensive product range including cooler boxes

Best For: Buyers prioritizing proven track record and high-volume production

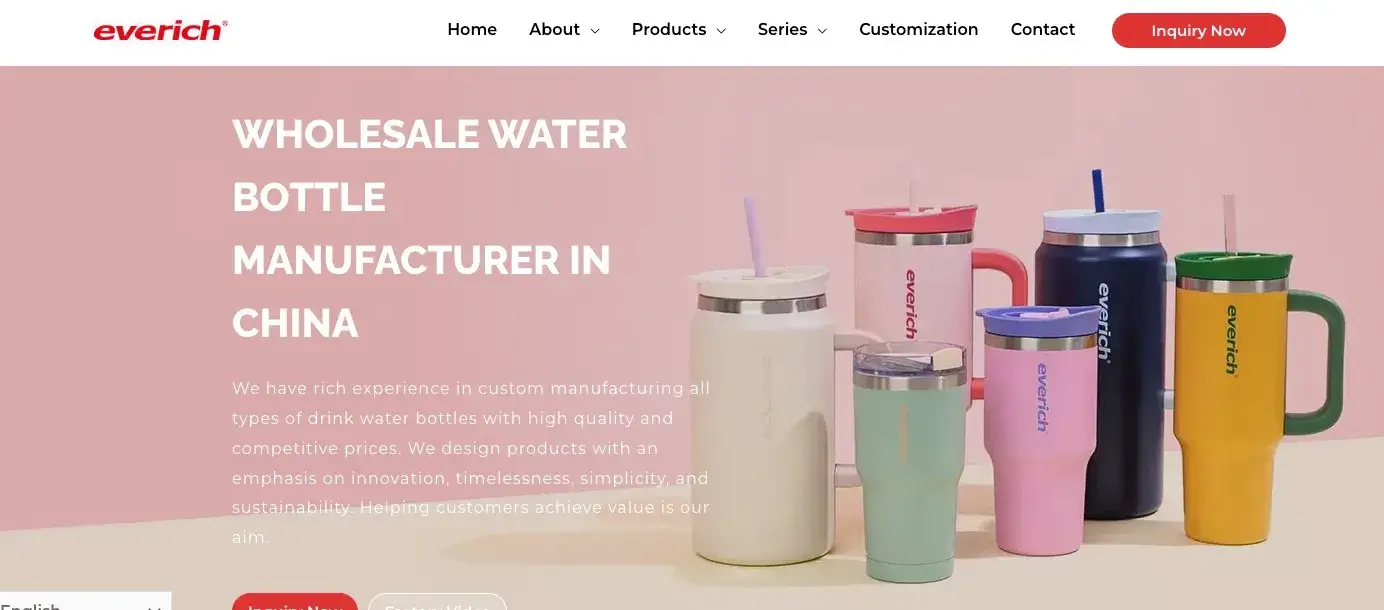

3. Everich - Sustainability Leader

Everich eco-friendly water bottles made from 90% recycled stainless steel materials

Established: 2000 | Production: 20 million pieces annually | Certifications: RCS, GRS, GLF, ISCC

Everich has positioned itself as the sustainability champion, achieving 90% recycling rates in their materials. Their focus on eco-friendly design resonates with environmentally conscious brands.

Key Strengths:

- Industry-leading sustainability certifications

- Strong OEM/ODM services for e-commerce

- Design innovation focus

- Competitive pricing for eco-friendly products

Best For: Brands emphasizing environmental responsibility and circular economy principles

Tier 2 - Specialized & Innovative Manufacturers

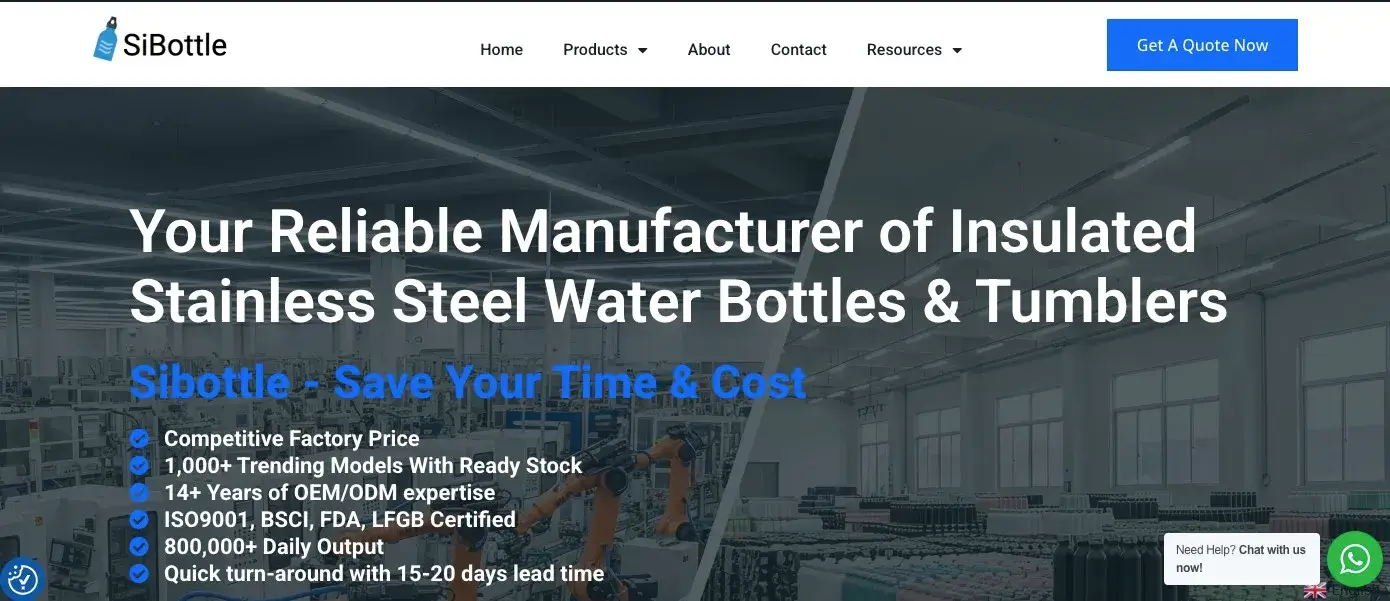

4. Sibottle - Competitive Price & Large Volume Expert

Sibottle's large-scale production facility showcasing high-volume manufacturing capabilities

Location: Yongkang | Factory Size: 18,000 sqm | Monthly Production: 800,000+ products | Certifications: ISO9001, BSCI, SEDEX

Having worked closely with Sibottle, I can attest to their commitment to delivering exceptional value through competitive pricing and large-volume production capabilities. Their 800,000+ monthly production capacity combined with industry-leading pricing makes them ideal for businesses requiring substantial quantities.

Key Strengths:

- Large-volume production capacity (800,000+ pieces monthly)

- Competitive MOQ starting from 1,000 pieces

- 14+ years of specialized expertise

- 5 automated production lines with robotic assembly

- 3D printing equipment for rapid prototyping

- 12-hour response guarantee

- 1000+ design options available

- 20-25 day lead time

Unique Advantages:

- Highly Competitive Pricing: Excellent supply chain management and large-scale production deliver market-winning prices

- Quality Guaranteed: Food-safe materials meeting FDA and LFGB standards

- Professional Factory: BSCI audited with ISO9001 certification

- Global Reach: Serving North America, Europe, Vietnam, Korea, South America

Best For: Medium to large businesses requiring high volumes, competitive pricing, and reliable quality delivery

Visit Sibottle's website to explore their full range of capabilities and contact their team for personalized consultation.

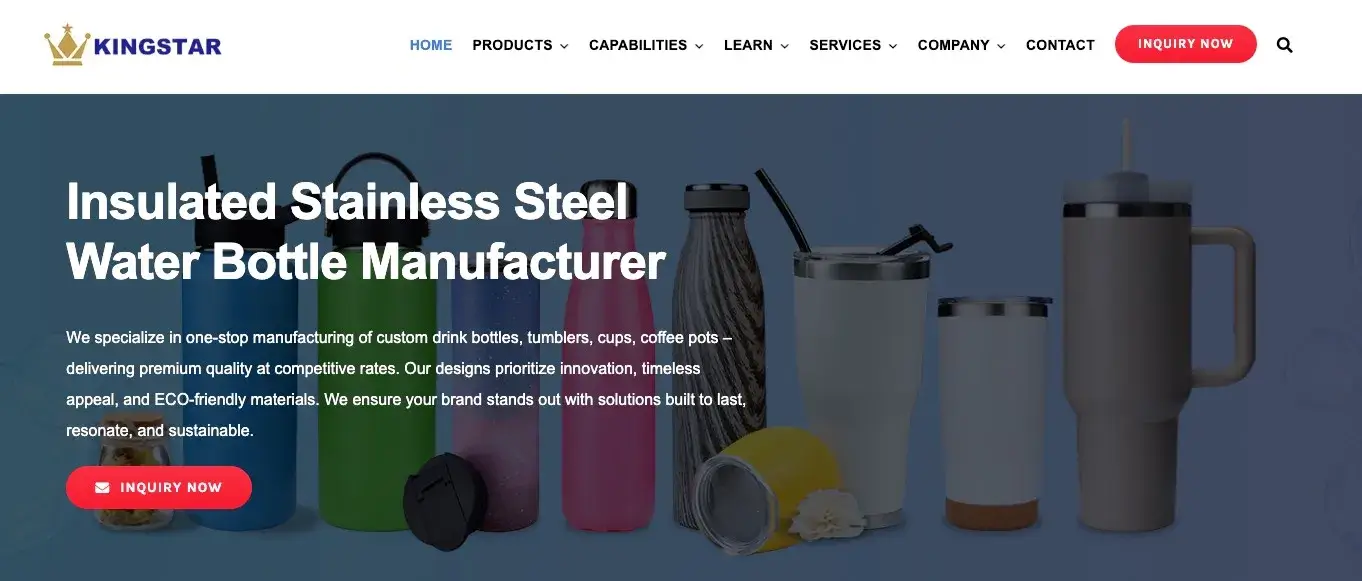

5. KingStar - High-End Design Focus

Established: 2002 | Location: Shanghai | Factory Size: 30,000 sqm | Team: 900+ employees

KingStar targets the premium market segment with sophisticated design capabilities and advanced R&D facilities.

Key Strengths:

- Large skilled workforce (900+ employees)

- Premium product positioning

- Advanced R&D for innovative designs

- Shanghai location advantage

Best For: Luxury brands and premium market positioning

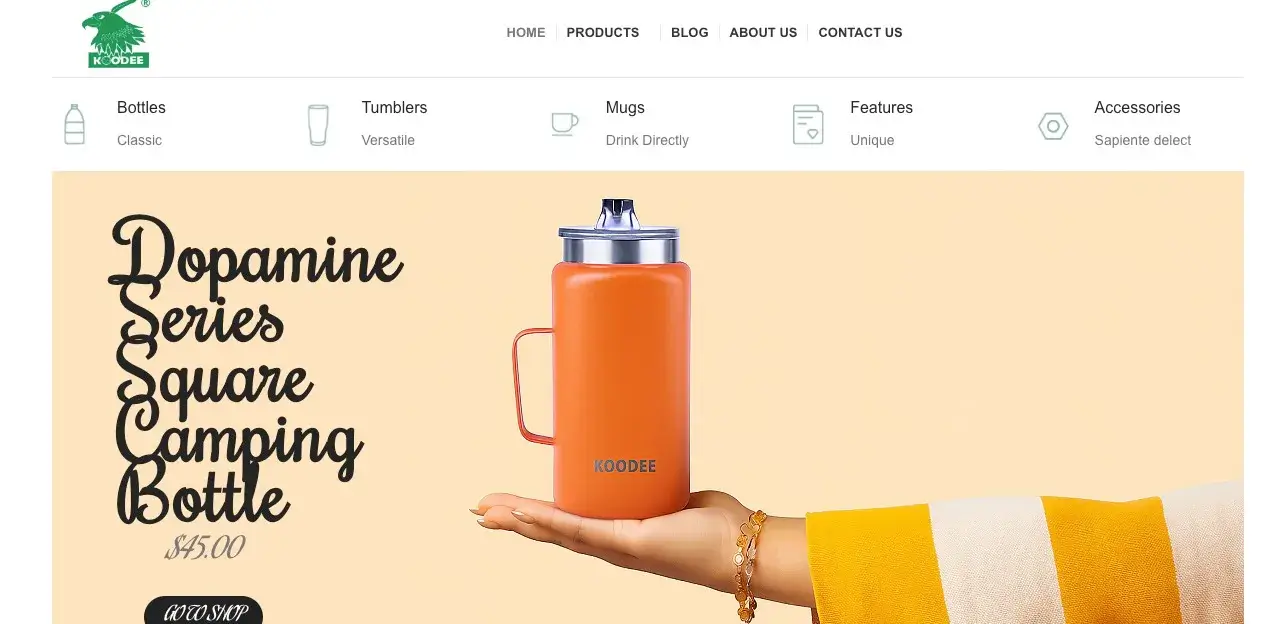

6. Koodee - High-Volume Production

Established: 2000 | Location: Guangzhou | Production: 600,000+ pcs/month | Certifications: SGS, CE, EN71

Koodee excels in sports bottle manufacturing with impressive monthly production capacity and strong safety certifications.

Key Strengths:

- High monthly production capacity

- Sports bottle specialization

- International safety compliance

- Pyrex glass bottle options

Best For: Sports brands and high-volume requirements

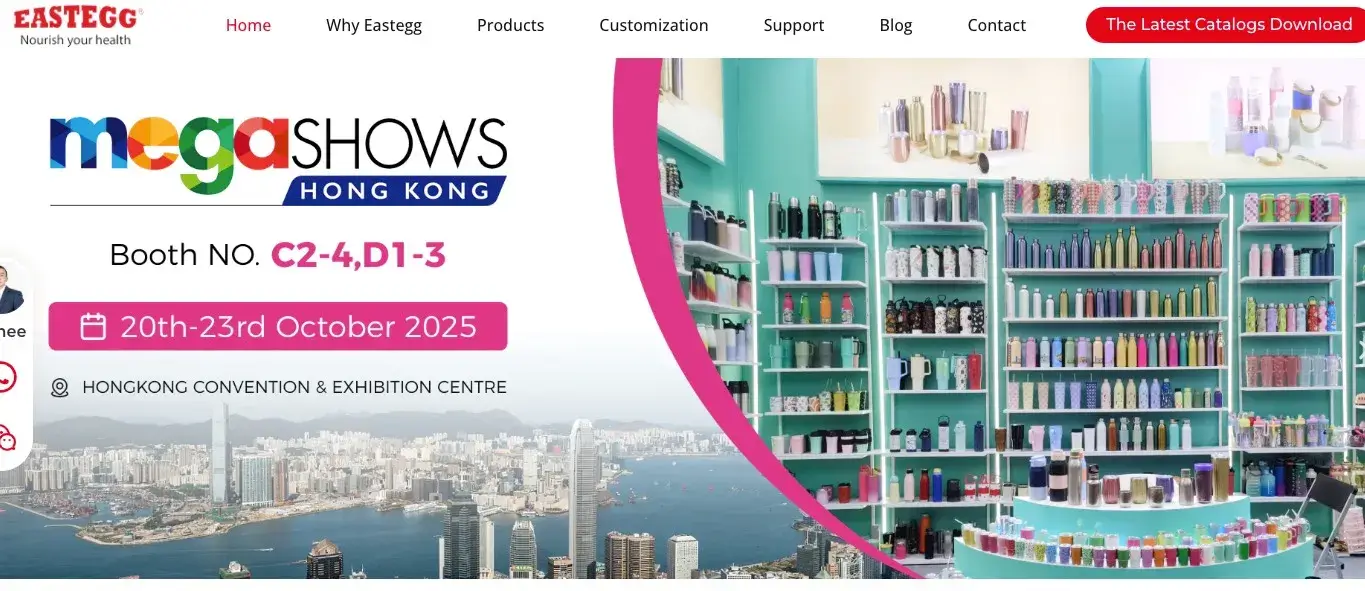

Tier 3 - Emerging & Niche Players

7. LaiKoe - One-Stop Solutions

LaiKoe's comprehensive product range from sports bottles to wine flasks

Established: ~2005 | Experience: 20+ years | Location: Zhejiang

LaiKoe positions itself as a comprehensive solution provider with diverse product categories beyond traditional water bottles.

Key Strengths:

- Diverse product portfolio (food flasks, wine flasks)

- One-stop sourcing solutions

- Strong R&D team

- 20+ years industry experience

Best For: Buyers seeking product diversity and comprehensive sourcing

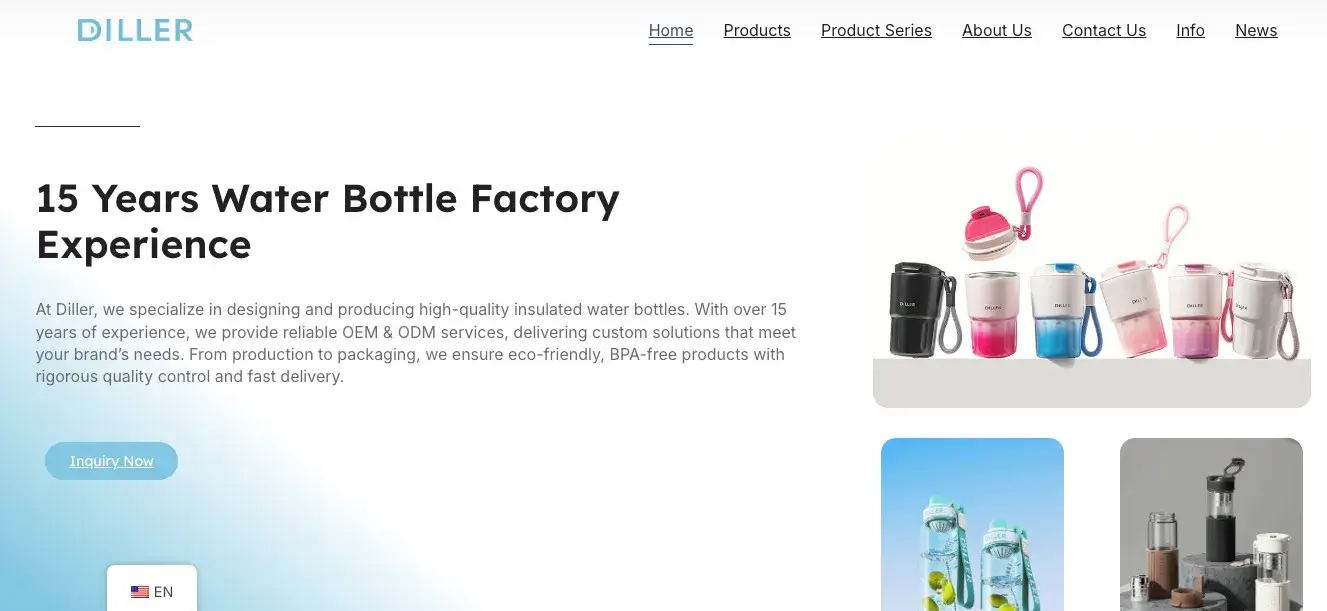

8. Diller - OEM/ODM Specialist

Established: 2009 | Location: Guangzhou | Production: 10,000+ pieces/day

Diller focuses specifically on OEM/ODM services with environmental safety as a core value proposition.

Key Strengths:

- OEM/ODM specialization

- Environmental safety focus

- Competitive daily production

- Glass and plastic options available

Best For: Private label brands and custom product development

9. Auland - Automated Production

Established: 1997 | Production: 50,000 pcs/day | Automation: 10 production lines

Auland leverages automation for consistent high-volume production with minimal human error.

Key Strengths:

- High automation levels

- Consistent daily output

- Part of established Sellers Union Group

- Vacuum tumbler specialization

Best For: Brands prioritizing production consistency and automation

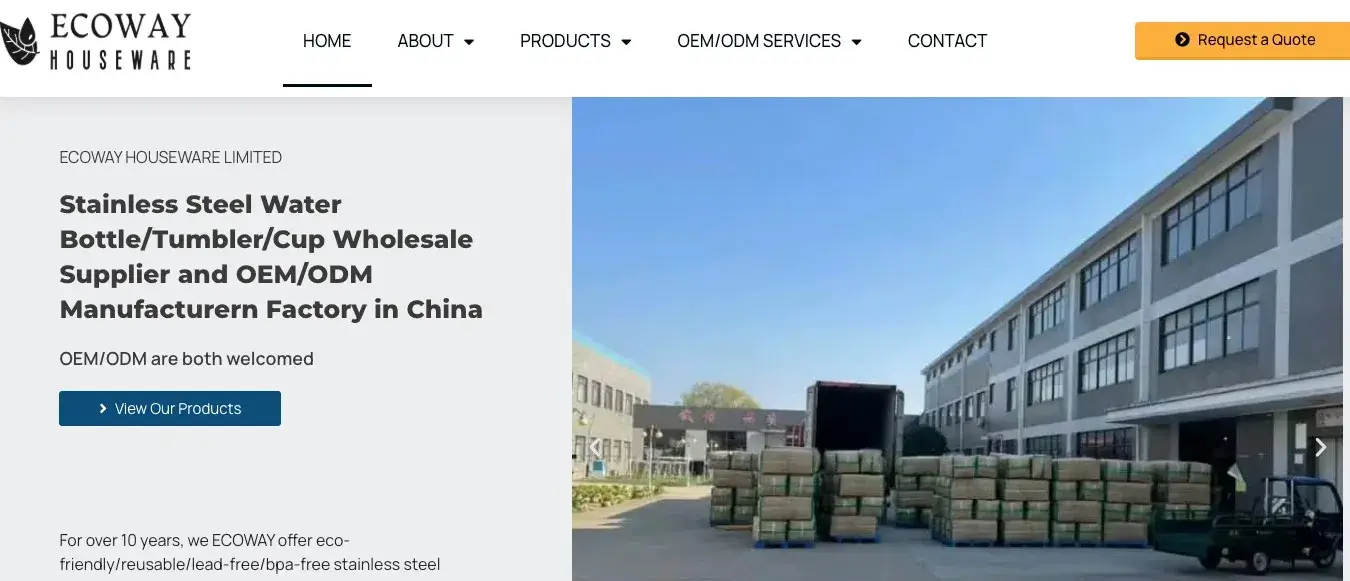

10. Ecoway - Flexible MOQ Options

Established: 2014 | Production: 500,000+ units/month | Global Reach: 30+ countries

Ecoway offers exceptional flexibility with MOQs ranging from 100 to 3,000 units, making them accessible to various business sizes.

Key Strengths:

- Ultra-flexible MOQ (100-3,000 units)

- Strong certification portfolio

- Global distribution network

- Custom tumbler specialization

Best For: Testing new markets and small batch requirements

For specialized insulated steel tumbler manufacturing, several of these manufacturers offer excellent capabilities.

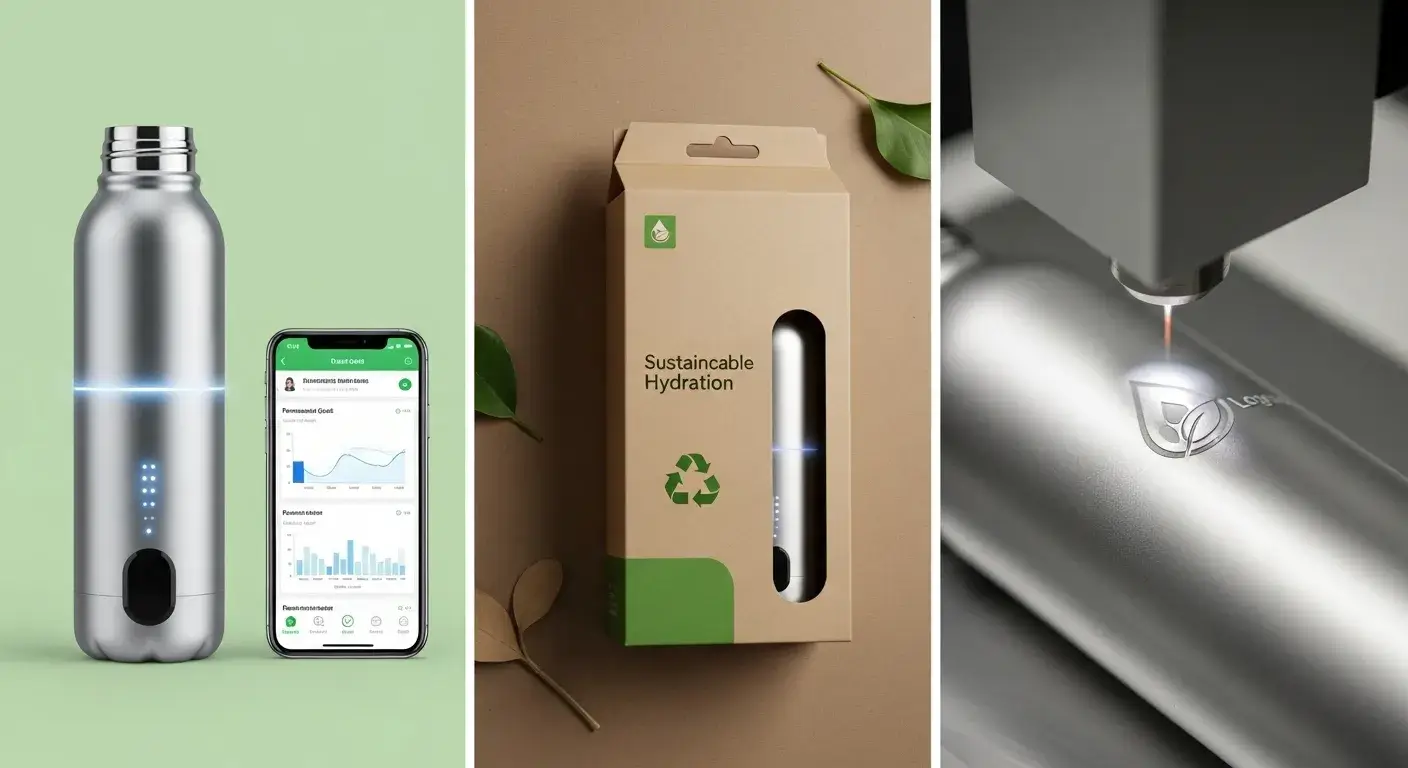

2025 Industry Trends Shaping Your Sourcing Decisions

Collage showing 2025 trends: smart bottles, sustainable materials, and customization options

Based on my industry observations and market research, these trends will significantly impact sourcing decisions in 2025:

Sustainability Requirements Buyers Demand

Environmental consciousness isn't just a trend—it's becoming a requirement. Manufacturers like Haers and GINT are investing heavily in solar energy, while Everich achieves 90% material recycling rates. According to Environmental Protection Agency guidelines, sustainable packaging will become increasingly regulated.

Smart Bottle Technology Adoption

The integration of IoT technology in water bottles is accelerating. Features like hydration tracking, temperature monitoring, and smartphone connectivity are transitioning from novelty to necessity, particularly in health and wellness markets.

Customization and Personalization Trends

Brands are demanding unique designs to stand out in crowded markets. Technologies like UV printing, laser engraving, and 3D printing are enabling unprecedented customization levels.

Supply Chain Resilience Factors

Recent global events have highlighted the importance of supply chain stability. Manufacturers with diversified production locations and robust logistics networks will have competitive advantages.

How to Choose the Right Partner for Your Business

For Small Businesses (Christina's Profile)

If you're like Christina—building your brand with limited initial capital—focus on these priorities:

MOQ Flexibility: Look for manufacturers offering 500-1,000 piece minimums. Companies like Sibottle and Ecoway excel here.

Customization Support: Ensure your manufacturer provides design assistance and prototyping. This is crucial when you lack production knowledge.

Responsive Communication: Choose suppliers guaranteeing quick response times. Sibottle's 12-hour response commitment exemplifies this standard.

Quality Assurance: Verify FDA and LFGB certifications for market compliance. Request samples before committing to large orders.

For comprehensive guidance on evaluating manufacturers, read our detailed guide on [PLACEHOLDER_LINK: How to Choose Stainless Steel Water Bottle Manufacturers].

For Trading Companies (Jack's Profile)

If you're sourcing for resale or require large quantities with price sensitivity, prioritize these factors:

Price Competitiveness: Compare pricing across multiple suppliers, but don't sacrifice quality for marginal savings.

Quality Control Systems: Establish clear quality standards and inspection protocols. Manufacturers with ISO certifications typically have better processes.

Efficient Communication: Language barriers and time zones can cause delays. Choose suppliers with experienced international sales teams.

Reliable Delivery: Late shipments mean lost sales opportunities. Verify manufacturers' on-time delivery records.

Red Flags to Avoid

- Unrealistic Pricing: Extremely low quotes often indicate quality compromises

- Poor Communication: Delayed responses or unclear answers suggest operational issues

- Missing Certifications: Lack of relevant safety and quality certifications

- No Sample Policy: Legitimate manufacturers provide samples for evaluation

- Unclear Terms: Vague contract terms regarding quality, delivery, or payment

Questions to Ask Potential Suppliers

- What are your current production capacities and lead times?

- Can you provide client references from my target market?

- What quality control processes do you have in place?

- How do you handle defective products or quality issues?

- What payment terms and trade insurance options do you offer?

For comprehensive guidance on manufacturer evaluation, check our detailed manufacturing guide.

Expert Insights: What Successful Buyers Look For

Business meeting between international buyers and Chinese manufacturers discussing partnership

From my experience working with successful buyers, I've identified common patterns in their decision-making processes:

Case Study: European Wellness Brand Success

A European wellness company partnered with a mid-tier Chinese manufacturer offering 1,000-piece MOQs. By focusing on sustainable materials and custom design, they achieved 300% growth in their first year. The key was choosing a manufacturer that aligned with their brand values rather than simply the lowest price.

Case Study: US Corporate Gifting Company

A US corporate gifting company initially chose the cheapest supplier but faced quality issues and delivery delays. After switching to a manufacturer with strong certifications and communication protocols, their client satisfaction scores improved by 40%.

Common Mistakes to Avoid

-

Choosing Based on Price Alone: The cheapest option often leads to the highest total cost when factoring in quality issues and delays.

-

Ignoring Communication Quality: Poor communication during sourcing typically indicates poor service during production.

-

Skipping Sample Evaluation: Never place large orders without thoroughly testing samples.

-

Overlooking Cultural Differences: Understanding Chinese business practices improves relationship building and negotiation outcomes.

Industry Insider Tips

- Visit During Canton Fair: The Canton Fair provides excellent opportunities to meet multiple manufacturers efficiently

- Build Long-term Relationships: Chinese business culture values long-term partnerships over transactional relationships

- Understand Payment Norms: Most manufacturers prefer 30% deposits with 70% payment before shipment

- Plan for Chinese Holidays: Chinese New Year and other holidays can significantly impact production schedules

Successful long-term partnerships in Chinese manufacturing are built on mutual respect, clear communication, and aligned quality standards.

Making Your Final Decision - A Step-by-Step Guide

Supplier Evaluation Checklist

Phase 1: Initial Screening

- [ ] Verify business license and export credentials

- [ ] Check factory certifications (ISO, BSCI, etc.)

- [ ] Review company website and product portfolio

- [ ] Confirm production capacity matches your needs

- [ ] Evaluate communication responsiveness

Phase 2: Detailed Assessment

- [ ] Request detailed quotations with specifications

- [ ] Ask for client references and contact them

- [ ] Review quality control processes and testing procedures

- [ ] Understand payment terms and trade protection options

- [ ] Clarify delivery schedules and shipping arrangements

Phase 3: Sample Evaluation

- [ ] Order samples of relevant products

- [ ] Test for quality, durability, and safety compliance

- [ ] Evaluate packaging and presentation

- [ ] Assess customization quality and accuracy

- [ ] Compare samples against your specifications

Product quality testing laboratory showing various testing equipment and sample bottles

Sample Ordering Process

- Identify Requirements: Clearly specify size, color, features, and any customization needs

- Request Quotations: Get detailed quotes including sample costs and shipping

- Place Sample Orders: Most manufacturers charge $30-100 per sample plus shipping

- Evaluate Thoroughly: Test functionality, materials, and overall quality

- Provide Feedback: Communicate any necessary adjustments before bulk ordering

Quality Verification Steps

Material Testing: Verify stainless steel grade (304 or 316) and food safety compliance

Functionality Testing: Check vacuum insulation performance and leak resistance

Durability Testing: Assess resistance to drops, scratches, and daily wear

Safety Testing: Ensure compliance with relevant safety standards (FDA, LFGB, etc.)

Contract Negotiation Tips

- Price Structure: Negotiate based on order volume and long-term commitment

- Quality Standards: Specify acceptable quality levels and defect rates

- Delivery Terms: Include penalties for late delivery and quality issues

- Payment Protection: Use trade assurance or letters of credit for large orders

- Intellectual Property: Protect your designs and branding through clear agreements

For additional support in your sourcing journey, you can learn more about Sibottle's approach to manufacturing excellence.

Conclusion

Choosing the right stainless steel water bottle manufacturer in China for 2025 requires balancing multiple factors: production capacity, quality standards, customization capabilities, and cost effectiveness. The manufacturers highlighted in this guide—from industry giants like Haers and GINT to specialized providers like Sibottle and Ecoway—each offer unique advantages for different business needs.

The key to success lies in aligning your manufacturer choice with your specific business requirements. Small businesses benefit from low-MOQ specialists, while large corporations can leverage high-volume manufacturers for better pricing. Sustainability-focused brands should prioritize manufacturers with strong environmental credentials, while technology-forward companies might prefer suppliers investing in smart bottle innovations.

As the market continues growing toward the projected $2.08 billion by 2032, early partnerships with the right manufacturers will provide competitive advantages through better pricing, priority production slots, and collaborative product development opportunities.

Ready to find your ideal manufacturing partner?

Whether you're just starting your journey or looking to optimize your current supply chain, the right manufacturer can transform your business. Contact Sibottle's expert team today for a personalized consultation and discover how our low-MOQ approach, 14+ years of experience, and commitment to quality can accelerate your success.

Take the next step:

- Request samples to evaluate quality firsthand

- Schedule a factory virtual tour to see our capabilities

- Get personalized quotations based on your specific requirements

- Access our complete manufacturing guide for in-depth industry insights

Don't let sourcing challenges hold back your business growth. Start your partnership with Sibottle today and join hundreds of successful brands who've transformed their product lines with our manufacturing expertise.