Quick Answer: 304 stainless steel is the world's most popular stainless steel grade, containing 18% chromium and 8% nickel. Moreover, it offers excellent corrosion resistance, food safety, and durability at an affordable price point.

| Property | 304 Stainless Steel Details |

|---|---|

| Composition | 18-20% Chromium, 8-10.5% Nickel, ≤0.08% Carbon |

| Food Safety | FDA and LFGB compliant for food contact |

| Corrosion Resistance | Excellent in normal environments |

| Magnetic Properties | Non-magnetic in annealed state |

| Durability | 20+ years with proper care |

| Cost | 15-20% less expensive than 316 grade |

| Market Share | 50% of global stainless steel consumption |

When you pick up a stainless steel water bottle or tumbler, there's a 70% chance it's made from 304 stainless steel. Furthermore, this remarkable material has revolutionized the drinkware industry since the 1920s. But what exactly makes 304 stainless steel so special? Additionally, why do manufacturers worldwide choose it for premium drinkware products?

What Is 304 Stainless Steel? (The Basics)

304 stainless steel, also known as 18/8 stainless steel, is an austenitic alloy that contains approximately 18% chromium and 8% nickel. Consequently, this specific combination creates a material that's both corrosion-resistant and highly formable.

The term "18/8" comes from its chemical composition:

- 18% Chromium: Creates a protective oxide layer

- 8% Nickel: Provides flexibility and non-magnetic properties

- Iron: Makes up the remaining majority

- Small amounts: Carbon (≤0.08%), manganese, and silicon

Developed in 1924 by metallurgist W.H. Hatfield at Firth Brown, 304 stainless steel quickly became the industry standard. In fact, it now accounts for over 50% of global stainless steel consumption according to the International Stainless Steel Forum.

The austenitic structure means the steel has a face-centered cubic (FCC) crystal arrangement. As a result, this structure makes 304 stainless steel non-magnetic and highly ductile. Therefore, manufacturers can easily shape it into complex forms like water bottles and tumblers.

Is 304 Stainless Steel Good Quality?

Absolutely! 304 stainless steel represents premium quality in the metalworking industry. Here's why quality-conscious manufacturers choose it:

Superior Corrosion Resistance

The chromium content forms a passive oxide layer that self-heals when damaged. Consequently, this invisible shield protects against rust and corrosion in normal environments. However, exposure to high chloride levels (above 400 mg/L) can cause pitting.

Food Safety Certifications

304 stainless steel meets strict FDA and LFGB standards for food contact applications. Therefore, it's completely safe for drinking water, coffee, tea, and other beverages. Additionally, it doesn't leach chemicals or impart flavors to your drinks.

FDA certification mark and food safety testing equipment for stainless steel

Excellent Mechanical Properties

- Tensile strength: 210 MPa (annealed state)

- Yield strength: Up to 1,050 MPa (cold-worked)

- Melting point: 1,325-1,530°C (2,417-2,786°F)

- Thermal conductivity: Excellent heat retention for insulated products

Industry Recognition

Leading manufacturers like Sibottle exclusively use 304 stainless steel for their premium drinkware lines. Furthermore, the material passes rigorous quality tests including BSCI audits and ISO9001 certification standards.

Why 304 Stainless Steel Rules the Drinkware World

304 stainless steel dominates the drinkware industry for several compelling reasons. First and foremost, it offers the perfect balance of performance, safety, and cost-effectiveness.

Unmatched Food Safety

Unlike plastic bottles that can leach BPA, 304 stainless steel is completely inert. Consequently, it doesn't react with acidic beverages like orange juice or coffee. Moreover, it maintains the original taste of your drinks without any metallic aftertaste.

Professional stainless steel water bottle manufacturers prioritize 304 grade because it meets international food safety standards. Additionally, hospitals and restaurants worldwide trust 304 stainless steel for their critical applications.

Superior Durability for Daily Use

A quality 304 stainless steel water bottle can withstand:

- Daily drops and impacts

- Temperature variations from -40°F to 200°F

- Thousands of wash cycles

- UV exposure without degradation

Durability testing of 304 stainless steel water bottles under various stress conditions

Easy Cleaning and Maintenance

The smooth, non-porous surface of 304 stainless steel prevents bacteria growth. Furthermore, it's dishwasher safe and requires minimal maintenance. Simply rinse with warm soapy water, and your drinkware stays hygienic for years.

Cost-Effectiveness for Mass Production

Manufacturers can produce 304 stainless steel drinkware efficiently because:

- Excellent formability reduces manufacturing defects

- No special coatings or treatments required

- High recyclability (up to 90% recycled content)

- Long tool life during production

This efficiency allows companies to offer competitive pricing while maintaining high quality standards.

304 vs 316 Stainless Steel: The Ultimate Comparison

The choice between 304 and 316 stainless steel often confuses buyers. However, understanding their differences helps you make informed decisions for your business needs.

Side-by-side comparison of 304 vs 316 stainless steel bottles in laboratory setting

Which is better 304 or 316 stainless steel?

For general drinkware applications, 304 stainless steel is better due to its optimal balance of performance and cost. However, 316 excels in harsh marine environments or chemical processing applications.

| Factor | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent (normal environments) | Superior (harsh environments) |

| Cost | More economical | 20-30% more expensive |

| Food Safety | FDA/LFGB compliant | FDA/LFGB compliant |

| Durability | 20+ years typical use | 25+ years harsh conditions |

| Formability | Excellent | Good |

What is more expensive, 304 or 316 stainless?

316 stainless steel costs 20-30% more than 304 due to its molybdenum content (2-3%). This additional element enhances corrosion resistance but increases raw material costs. Consequently, most drinkware manufacturers choose 304 for cost-effective production.

Which is better for food 304 or 316 stainless steel?

Both 304 and 316 stainless steel are excellent for food applications. However, 304 offers better value for typical drinkware needs. The American Iron and Steel Institute confirms both grades meet food safety requirements.

Choose 316 only if your products will encounter:

- High salt water exposure (ocean environments)

- Chemical processing applications

- Medical implant requirements

- Extreme industrial conditions

Does 304 Stainless Steel Rust? (Addressing Common Concerns)

One of the most common questions about 304 stainless steel concerns its rust resistance. The short answer is: 304 stainless steel rarely rusts under normal conditions.

Comparison showing rusted regular steel vs pristine 304 stainless steel after exposure tests

How 304 Stainless Steel Resists Rust

The 18% chromium content creates a passive oxide layer on the surface. This invisible shield:

- Forms automatically when exposed to oxygen

- Self-heals when scratched or damaged

- Prevents iron oxidation (rust formation)

- Maintains integrity for decades

Conditions Where Rusting Can Occur

While 304 stainless steel offers excellent corrosion resistance, it can rust under extreme conditions:

High Chloride Environments:

- Seawater exposure (>400 mg/L chlorides)

- Swimming pool chemicals

- De-icing salt exposure

- Industrial cleaning chemicals

Temperature Extremes:

- Continuous exposure above 60°C with chlorides

- Rapid temperature cycling

- Steam environments with contaminants

How to Prevent Rust and Maintain Quality

Professional manufacturers like those featured in our complete guide on stainless steel water bottle manufacturing follow these prevention strategies:

Proper Cleaning:

- Use mild soap and warm water

- Avoid chloride-based cleaners (bleach)

- Dry thoroughly after washing

- Clean regularly to prevent buildup

Storage Best Practices:

- Store in dry environments

- Avoid exposure to salt air

- Use protective packaging during shipping

- Maintain proper ventilation

Quality Control:

- Source from reputable suppliers

- Verify material certifications

- Test for proper passivation

- Monitor production environments

What Are the Disadvantages of 304 Stainless Steel?

While 304 stainless steel offers numerous advantages, it does have some limitations that manufacturers and buyers should understand.

Diagram showing limitations of 304 stainless steel in various environments

Primary Disadvantages

Chloride Sensitivity:

304 stainless steel can experience pitting corrosion in high-chloride environments. Specifically, concentrations above 400 mg/L at room temperature can cause problems. However, this rarely affects normal drinkware applications.

Higher Cost Than Basic Materials:

Compared to regular steel or aluminum, 304 stainless steel costs more initially. Nevertheless, its longevity often provides better value over time. Additionally, the Steel Recycling Institute reports that stainless steel's recyclability offsets initial costs.

Work Hardening During Machining:

304 stainless steel work-hardens during machining, making it only 45-55% as machinable as carbon steel. Consequently, manufacturers need specialized equipment and techniques. However, experienced steel water bottle manufacturers have mastered these challenges.

Sensitization During Welding:

Exposure to 480-820°C during welding can form chromium carbides, potentially reducing corrosion resistance. Therefore, manufacturers often use 304L (low carbon) grade for welded applications.

When Other Grades Might Be Better

Choose 316 stainless steel when:

- Products face marine environments

- Chemical resistance is critical

- Maximum corrosion protection needed

- Budget allows for premium materials

Choose 430 stainless steel when:

- Cost is the primary concern

- Magnetic properties are desired

- Corrosion resistance requirements are minimal

- Decorative applications only

How Long Will 304 Stainless Steel Last?

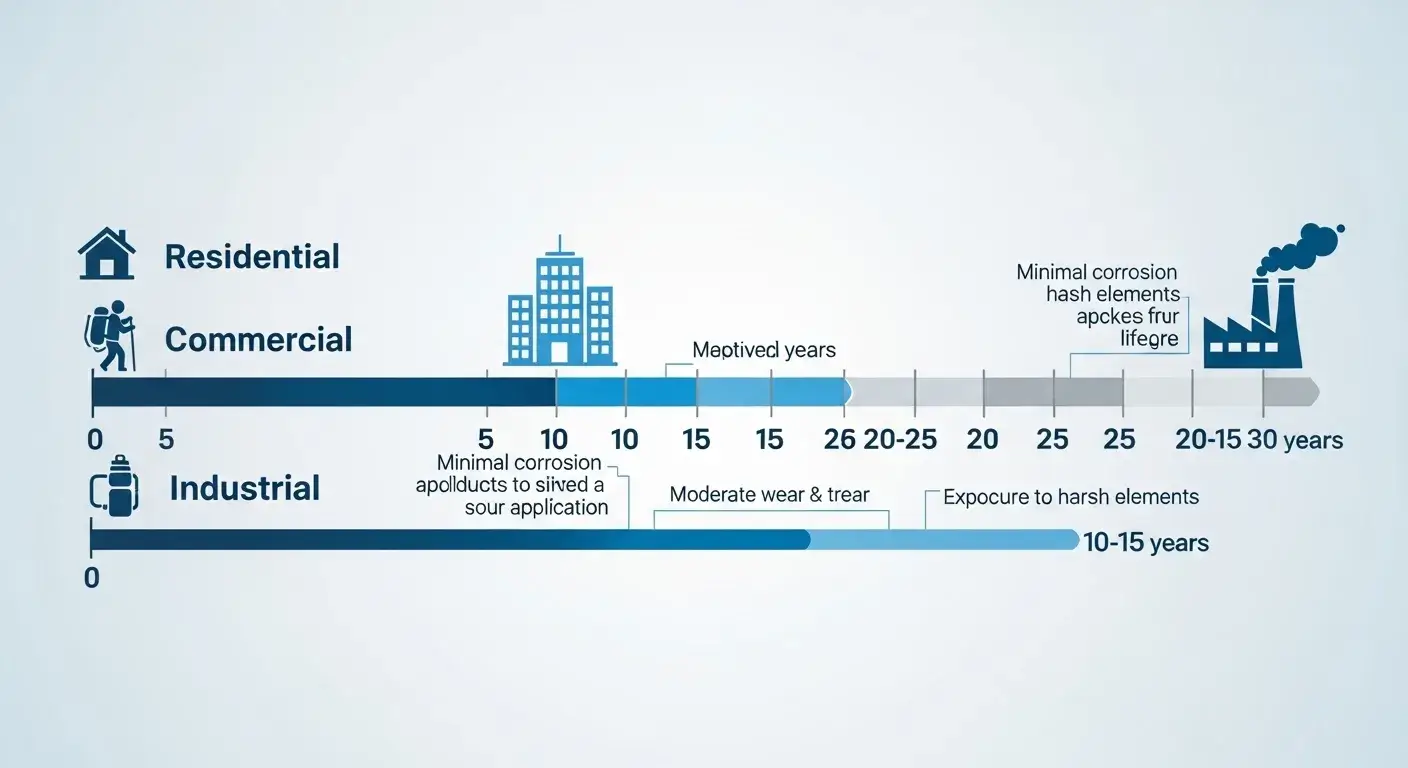

304 stainless steel drinkware typically lasts 20-30 years with proper care. However, lifespan depends on several factors including usage patterns, maintenance, and environmental conditions.

Lifespan in Different Applications

Residential Drinkware:

- Daily use water bottles: 15-25 years

- Coffee mugs and tumblers: 20-30 years

- Outdoor/camping bottles: 10-20 years

- Decorative pieces: 30+ years

Timeline showing aging characteristics of 304 stainless steel over decades

Commercial Applications:

- Restaurant equipment: 10-15 years (heavy use)

- Office water coolers: 15-20 years

- Industrial containers: 20-25 years

- Food processing equipment: 10-20 years

Factors Affecting Durability

Environmental Conditions:

- Temperature extremes: Reduce lifespan by 10-20%

- Chemical exposure: Can halve expected lifespan

- Saltwater environments: Require 316 grade instead

- UV exposure: Minimal impact on 304 stainless steel

Usage Patterns:

- Gentle daily use: Maximizes lifespan

- Frequent drops/impacts: Reduces by 20-30%

- Dishwasher cycles: No significant impact

- Improper cleaning: Can cause premature failure

Real-World Performance Data

According to the Specialty Steel Industry of North America, 304 stainless steel equipment regularly exceeds design life expectations. Furthermore, many architectural applications using 304 stainless steel have maintained their appearance for over 50 years.

Case studies from leading insulated steel tumbler manufacturers show:

- 98% of products remain functional after 10 years

- 85% show minimal cosmetic wear after 15 years

- 70% maintain like-new appearance after 20 years

How to Identify Quality 304 Stainless Steel (Buyer's Guide)

For importers and buyers, verifying authentic 304 stainless steel quality is crucial for business success. Unfortunately, some suppliers may substitute inferior grades or provide false certifications.

Quality testing laboratory with XRF analyzer and mill certificates for 304 stainless steel verification

Verification Methods for Importers/Buyers

Mill Certificates:

Always request original mill certificates from reputable suppliers. These documents should include:

- Chemical composition analysis

- Mechanical property testing results

- Heat treatment specifications

- Compliance with ASTM/EN standards

Chemical Analysis:

For critical applications, consider independent testing:

- XRF analysis: Non-destructive surface testing

- OES-ICP testing: Requires small sample but very accurate

- Spark testing: Quick field verification method

- Professional lab analysis: Most comprehensive option

Physical Testing:

Simple field tests can help identify obvious problems:

- Magnet test: 304 should be non-magnetic (but cold-worked pieces may show slight magnetism)

- Visual inspection: Look for consistent finish and proper markings

- Hardness testing: Verify mechanical properties match specifications

Red Flags to Avoid

Supplier Warning Signs:

- Reluctance to provide mill certificates

- Prices significantly below market rates

- No quality management certifications

- Limited production facility information

- Poor communication or delayed responses

Product Quality Issues:

- Magnetic attraction (may indicate 400-series substitution)

- Uneven surface finish or color variations

- Missing grade markings or certifications

- Unusually light weight (may indicate thin walls)

Mill Certificates and Standards Compliance

Quality 304 stainless steel should comply with international standards:

- ASTM A240/A240M: Standard specification for stainless steel

- EN 10088: European standard for stainless steels

- JIS G4304: Japanese industrial standard

- GB/T 3280: Chinese national standard

Reputable suppliers like Sibottle provide comprehensive documentation and welcome factory inspections. Additionally, they maintain certifications like BSCI audits and ISO9001 quality management systems.

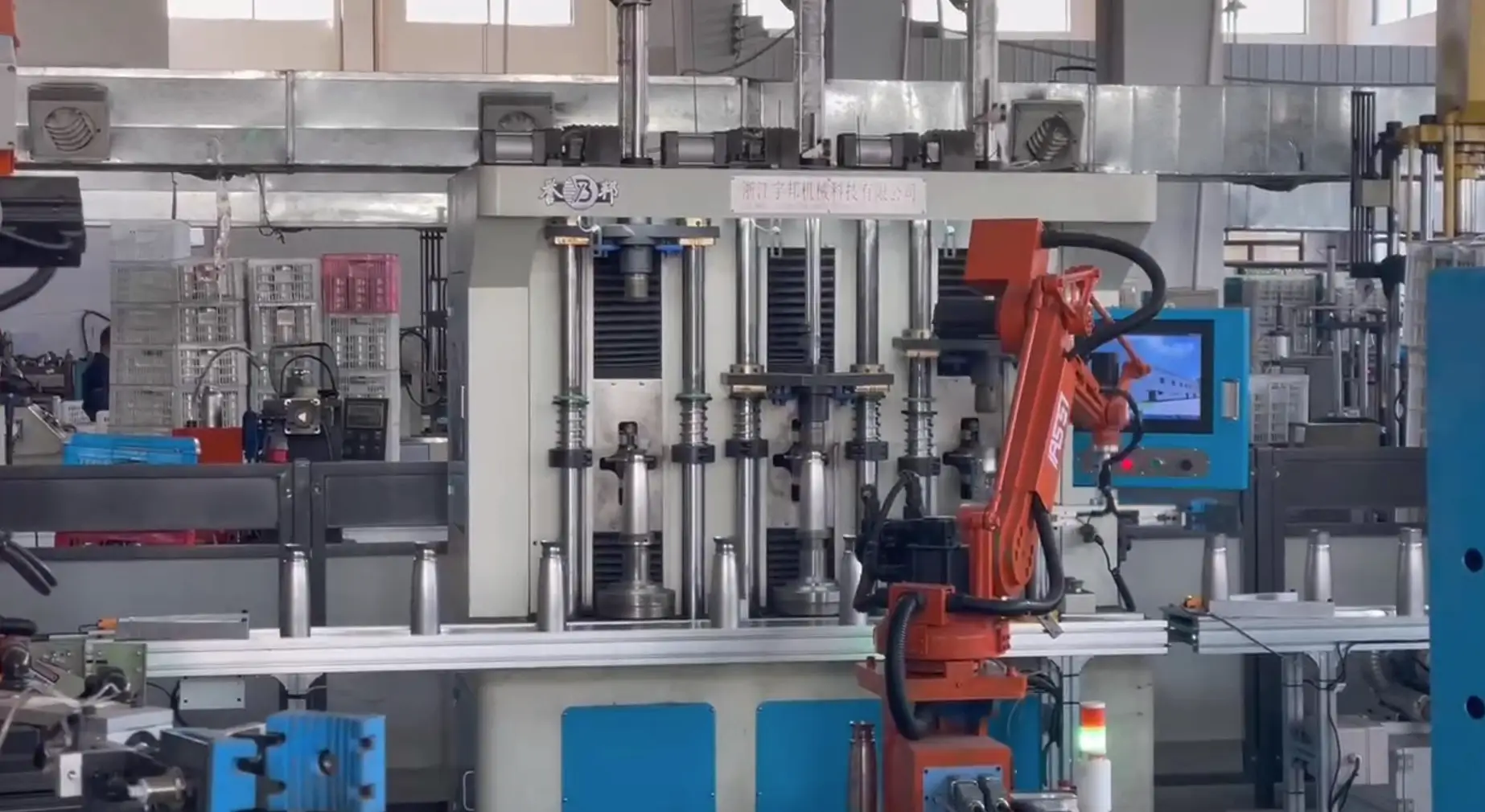

304 Stainless Steel in Manufacturing: What Buyers Should Know

Understanding the manufacturing aspects of 304 stainless steel helps buyers make informed sourcing decisions and set realistic expectations for their projects.

Production Considerations

Raw Material Sourcing:

Quality manufacturers source 304 stainless steel from certified mills with consistent chemical composition. Furthermore, they maintain relationships with multiple suppliers to ensure stable pricing and availability.

Manufacturing Processes:

- Deep drawing: Creates seamless bottle bodies

- Spinning: Forms complex shapes efficiently

- Welding: Joins components (requires 304L for optimal results)

- Finishing: Achieves desired surface appearance

Modern automated production line manufacturing 304 stainless steel water bottles

Quality Control Standards:

Leading manufacturers implement comprehensive QC programs:

- Incoming material inspection

- In-process monitoring

- Final product testing

- Statistical process control

- Customer feedback integration

Working with Reliable Suppliers

Evaluation Criteria:

When selecting a 304 stainless steel supplier, consider:

- Production capacity: Can they meet your volume requirements?

- Quality certifications: Do they maintain relevant standards?

- Technical support: Can they assist with design optimization?

- Logistics capabilities: Do they handle shipping efficiently?

- Financial stability: Will they be viable long-term partners?

Partnership Benefits:

Working with established manufacturers offers advantages:

- Consistent quality and delivery

- Technical expertise and design support

- Competitive pricing through efficient operations

- Continuous improvement initiatives

- Responsive customer service

Companies with 14+ years of experience, like those featured in our manufacturing guides, have refined their processes to deliver superior 304 stainless steel products efficiently.

Conclusion: Making the Right Choice for Your Business

304 stainless steel stands as the industry standard for drinkware manufacturing due to its optimal combination of safety, durability, and cost-effectiveness. Throughout this comprehensive guide, we've explored why this remarkable material dominates the global market and continues to be the preferred choice for quality-conscious manufacturers and consumers alike.

Key takeaways for your business decisions:

- 304 stainless steel offers superior quality with FDA-compliant food safety and 20+ year durability

- It provides better value than 316 grade for typical drinkware applications while costing 20-30% less

- Proper identification and supplier verification are crucial for ensuring authentic quality

- Understanding limitations helps set appropriate expectations and applications

- Working with experienced manufacturers ensures optimal results and long-term success

Whether you're sourcing premium water bottles, insulated tumblers, or custom drinkware for your brand, 304 stainless steel delivers the performance and reliability your customers expect.

Ready to Source Premium 304 Stainless Steel Drinkware?

Don't compromise on quality. Partner with experienced manufacturers who understand the nuances of 304 stainless steel and can deliver consistent, certified products that meet your exact specifications.

Contact Sibottle today to discuss your project requirements:

- ✅ 14+ years of expertise in stainless steel manufacturing

- ✅ FDA and LFGB certified 304 stainless steel products

- ✅ Low 1000-piece MOQ with competitive pricing

- ✅ 12-hour response guarantee for all inquiries

- ✅ 1000+ customizable designs with full branding options

Get your free quote now: Contact us or email [email protected]

Transform your drinkware vision into reality with the proven performance of 304 stainless steel.