When you pick up your favorite stainless steel water bottle, have you ever wondered where it actually came from?

After spending over 14 years in the stainless steel water bottle manufacturing industry, I've witnessed firsthand how this global market operates.

The answer might surprise you – but it's crucial information for both consumers and businesses making purchasing decisions.

Global stainless steel water bottle manufacturing facilities showing the concentration of production in key regions

Quick Answer: The Global Manufacturing Landscape at a Glance

Before diving deep, here's what you need to know right away:

| Manufacturing Hub | Market Share | Key Advantages | Popular Brands |

|---|---|---|---|

| China | 99% | Cost-effective, Advanced tech | Hydro Flask, Stanley, Klean Kanteen |

| USA | <1% | Quality control, Local production | Liberty Works, Select Nalgene |

| Other Countries | <1% | Premium/Niche markets | SIGG (Switzerland), RIVERS (Japan) |

This manufacturing distribution directly impacts everything from pricing to quality control. Moreover, understanding these patterns helps businesses make informed sourcing decisions. As someone who has worked with over 1000+ clients globally, I can tell you that manufacturing location significantly influences both cost and customization options.

The global stainless steel water bottle market reached USD 1.45 billion in 2024 and is projected to grow to USD 2.08 billion by 2032, with a CAGR of 4.6%. This growth is primarily driven by increasing environmental awareness and the shift away from single-use plastics.

Why China Dominates Stainless Steel Water Bottle Manufacturing

China produces an estimated 99% of all stainless steel water bottles worldwide. From my experience running Sibottle, I can explain exactly why this dominance exists.

The Supply Chain Advantage

China controls 56% of global stainless steel production, which creates several key advantages:

- Raw Material Access: Direct access to high-quality 304 and 316 stainless steel

- Cost Efficiency: Reduced transportation and import costs for materials

- Quality Consistency: Established relationships with steel suppliers ensure consistent material quality

At our facility, we benefit from this integrated supply chain daily. Furthermore, cities like Yongkang in Zhejiang Province have become specialized manufacturing hubs, earning the nickname "Capital of Insulated Cups."

Modern Chinese stainless steel water bottle production line showing automated manufacturing processes

Advanced Manufacturing Technology

Chinese manufacturers have invested heavily in automation and technology. For example:

- Automated Production Lines: Our facility operates 5 automated production lines capable of producing 800,000+ products monthly

- Precision Equipment: Advanced pipe drawing lines and robotic assembly systems

- Quality Control Systems: Rigorous testing protocols for leakage, insulation, and durability

This technological advancement allows us to offer competitive pricing while maintaining high quality standards. Additionally, the concentration of expertise in specific regions creates a knowledge ecosystem that benefits the entire industry.

Economic Factors

The cost advantages are substantial:

- Labor Costs: Significantly lower than Western countries

- Economies of Scale: Large production volumes reduce per-unit costs

- Infrastructure: Well-developed logistics and shipping networks

These factors enable Chinese manufacturers to offer customization services at prices ranging from $0.20 to $2.00 per bottle, depending on complexity.

Popular Brand Manufacturing Locations (Addressing Specific Questions)

Let me address the most common questions I receive about popular water bottle brands and their manufacturing origins.

Where is Hydro Flask Made?

Despite being an American brand, Hydro Flask bottles are manufactured in China. The company was founded in Oregon but moved production overseas to remain competitive. However, this doesn't compromise quality – many Chinese facilities maintain strict quality standards and certifications.

Where does Hydro Flask get their stainless steel? Hydro Flask sources high-grade 18/8 stainless steel from certified suppliers, primarily in China, where the majority of global stainless steel production occurs.

Is Stanley Water Bottle Made in the USA?

No, Stanley water bottles are not made in the USA. While Stanley has a long American heritage dating back to 1913, their current stainless steel water bottles are manufactured in China. This transition allows them to offer competitive pricing while maintaining their quality standards.

Comparison of popular water bottle brands and their actual manufacturing locations

Where is Klean Kanteen Made?

Klean Kanteen, despite being a California-based company, manufactures their stainless steel bottles in China. This is a perfect example of how even environmentally-focused American brands rely on Chinese manufacturing for cost-effectiveness and production capacity.

Where are Takeya Water Bottles Made?

Takeya water bottles are manufactured in China. The company focuses on design and quality control from their US headquarters while leveraging Chinese manufacturing capabilities for production.

Are Nalgene Water Bottles Made in the USA?

This is where it gets interesting. Nalgene's plastic bottles are indeed made in the USA (specifically in New York), but their stainless steel offerings are typically manufactured in China. The plastic bottles represent their core heritage product line.

Where are Kirkland Water Bottles Manufactured?

Kirkland Signature water bottles, sold at Costco, are manufactured in China. Like many private label products, they leverage Chinese manufacturing to offer competitive pricing to consumers.

Where is the Brita Water Bottle Made?

Brita water bottles, including their stainless steel models, are manufactured in China. The company focuses on filtration technology development while utilizing established manufacturing networks for production.

Are RTIC Water Bottles Made in the USA?

No, RTIC water bottles are not made in the USA. Despite being a Texas-based company, RTIC manufactures their stainless steel products in China to maintain competitive pricing in the market.

The Rare USA-Made Stainless Steel Water Bottles

While China dominates the market, some companies do manufacture stainless steel water bottles in the USA, though they face significant challenges.

Liberty Works: A Success Story

Liberty Works, based in Union Gap, Washington, represents one of the few successful USA-made stainless steel water bottle manufacturers. They produce vacuum-sealed, insulated bottles using ethically sourced materials.

Key Success Factors:

- Premium positioning and pricing

- Focus on ethical sourcing and production

- Strong brand story around American manufacturing

Why USA Production is Challenging

From my industry experience, several factors make USA production difficult:

- Equipment Costs: Vacuum insulation technology requires specialized, expensive equipment

- Labor Costs: Manufacturing wages in the USA are significantly higher

- Regulatory Compliance: Additional certifications and safety requirements increase costs

- Supply Chain: Limited domestic stainless steel processing capabilities

Cost Comparison Insights

Based on industry data:

- USA-made bottles: Typically cost 300-400% more to produce

- Chinese-made bottles: Benefit from integrated supply chains and lower labor costs

- Break-even point: USA manufacturers need to charge premium prices to remain viable

This explains why even American brands choose Chinese manufacturing for their steel water bottle production.

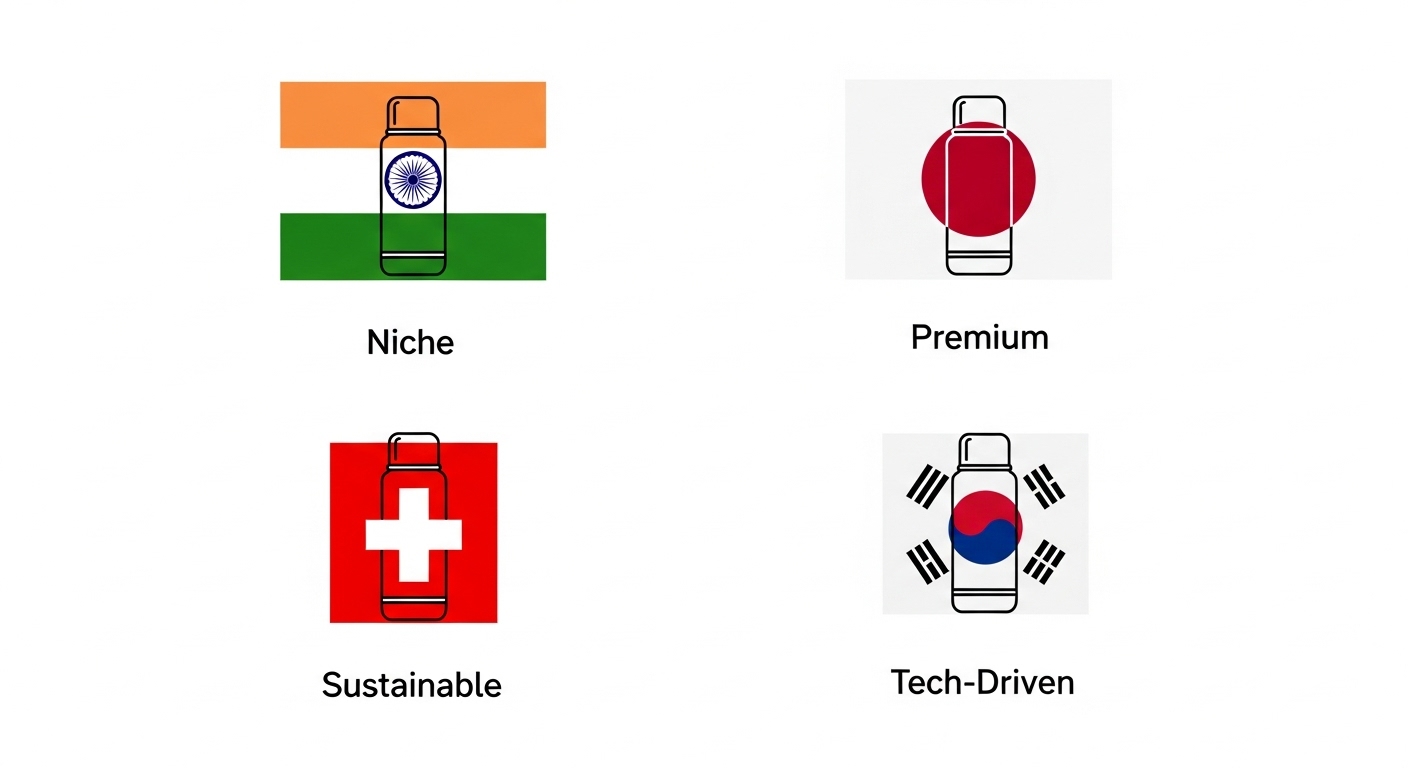

Other Global Manufacturing Hubs

While China dominates, other countries contribute to the global supply, particularly in niche markets.

India: The Emerging Player

India, as the world's second-largest stainless steel producer, has a growing water bottle manufacturing sector:

- Domestic Market Focus: Primarily serves the large Indian consumer market

- Export Potential: Increasing exports to neighboring countries

- Cost Advantage: Lower labor costs compared to developed countries

Japan: Premium Quality Focus

Japanese manufacturers emphasize precision and innovation:

- Advanced Features: Integration of antimicrobial coatings and smart technology

- Brand Collaboration: Companies like RIVERS work with lifestyle brands

- Premium Positioning: Focus on high-end, design-conscious consumers

Europe: Sustainability Leaders

European manufacturers, particularly in Germany, Italy, and Switzerland, focus on:

- Sustainable Production: Emphasis on environmental responsibility

- Design Innovation: Premium aesthetics and functionality

- Brand Heritage: Companies like SIGG leverage long-standing reputations

South Korea: Innovation Hub

South Korean manufacturers contribute through:

- Technology Integration: Smart features and connectivity

- Design Excellence: Focus on modern, minimalist aesthetics

- Regional Market: Serving Asian premium markets

These regional manufacturers typically serve specific market segments rather than competing directly with Chinese mass production.

How Manufacturing Location Affects Your Purchase Decision

As someone who has guided thousands of businesses through sourcing decisions, I understand how manufacturing location impacts various factors.

Quality Considerations

Chinese Manufacturing Quality:

- Modern facilities often exceed international standards

- Certifications include FDA, LFGB, and ISO 9001

- Rigorous testing protocols for safety and performance

At Sibottle, we conduct comprehensive testing including:

- Leakage tests under pressure

- Insulation performance verification

- Drop tests for durability

- Food safety compliance checks

USA Manufacturing Quality:

- Potentially stricter regulatory oversight

- Premium positioning often correlates with quality focus

- Limited production volumes allow for detailed attention

Cost Implications

Manufacturing location directly impacts pricing:

Chinese Manufacturing:

- Lower production costs enable competitive pricing

- Economies of scale reduce per-unit expenses

- Integrated supply chains minimize material costs

USA Manufacturing:

- Higher labor costs increase final prices

- Limited production volumes reduce economies of scale

- Premium positioning required for profitability

Sustainability Factors

Environmental Considerations:

- Transportation distance affects carbon footprint

- Local production reduces shipping emissions

- Some Chinese manufacturers adopt renewable energy

Social Responsibility:

- Labor standards vary by region and manufacturer

- Certifications like BSCI help ensure ethical practices

- Supply chain transparency becoming increasingly important

Brand Positioning

Manufacturing location influences brand perception:

- Made in USA: Appeals to patriotic consumers, premium positioning

- Made in China: Focus on value and functionality

- European Made: Emphasis on design and sustainability

What Makes a Quality Stainless Steel Water Bottle? (Regardless of Origin)

Quality transcends manufacturing location. Here's what to look for in any stainless steel water bottle:

Material Standards

Stainless Steel Grades:

- 304 Stainless Steel: Food-grade, rust-resistant, most common

- 316 Stainless Steel: Superior corrosion resistance, premium option

- 18/8 Stainless Steel: Another designation for 304 grade

Essential Certifications

Look for these quality markers:

- FDA Approved: Ensures food safety compliance

- LFGB Certified: European food safety standard

- BPA-Free: No harmful plastic components

- ISO 9001: Quality management certification

Production Standards

Key Quality Indicators:

- Double-wall vacuum insulation for temperature retention

- Leak-proof cap design with quality seals

- Smooth interior finish preventing bacterial growth

- Durable exterior coating resistant to scratches

Testing Protocols

Quality manufacturers implement rigorous testing:

- Pressure Testing: Ensures leak-proof performance

- Temperature Retention: Verifies insulation effectiveness

- Drop Tests: Confirms durability under normal use

- Chemical Analysis: Validates material safety

At our manufacturing facility, we test every batch to ensure consistent quality regardless of order size.

The Business Perspective: Why Brands Choose Chinese Manufacturing

Having worked with over 1000+ clients from various industries, I can share insights into why businesses choose Chinese manufacturing.

OEM/ODM Advantages

Original Equipment Manufacturing (OEM):

- Established production processes

- Proven quality systems

- Cost-effective scaling

Original Design Manufacturing (ODM):

- In-house design capabilities

- Rapid prototyping services

- Complete product development support

Customization Capabilities

Chinese manufacturers excel in customization:

Design Options:

- Laser engraving and UV printing

- Custom colors and finishes

- Unique cap and handle designs

- Packaging customization

Technical Specifications:

- Various capacity options (12oz to 64oz)

- Different insulation requirements

- Specialized features (straws, filters, etc.)

- Brand-specific accessories

Various customization options available for stainless steel water bottles

Lead Times and MOQ Considerations

Typical Chinese Manufacturing Parameters:

- Lead Time: 20-25 days for standard orders

- Minimum Order Quantity: Starting from 1,000 pieces

- Sample Time: 5-7 days for existing designs

- Custom Design: 10-15 days for new tooling

- Monthly Capacity: 800,000+ products for established manufacturers

These parameters make Chinese manufacturing attractive for businesses ranging from medium-sized companies to large corporations looking for reliable, scalable production.

Supply Chain Integration

Chinese manufacturers offer comprehensive services:

- Raw material sourcing

- Component manufacturing

- Assembly and testing

- Packaging and shipping

- Quality assurance

This integration simplifies the procurement process for international brands.

Future Trends in Stainless Steel Water Bottle Manufacturing

The industry is evolving rapidly, and manufacturing locations are adapting to new trends.

Smart Technology Integration

Emerging Features:

- Temperature monitoring displays

- Hydration tracking capabilities

- Bluetooth connectivity

- LED indicators

Chinese manufacturers are leading this innovation, with companies investing heavily in smart manufacturing capabilities.

Sustainability Initiatives

Environmental Focus:

- Increased use of recycled stainless steel (90%+ recycling rate)

- Solar-powered manufacturing facilities

- Reduced packaging waste

- Carbon-neutral shipping options

Customization Trends

Market Demands:

- Personalized designs for individual consumers

- Corporate branding opportunities

- Limited edition collaborations

- Seasonal and themed collections

Our insulated tumbler manufacturing division has seen 300% growth in custom orders over the past two years.

Future smart water bottle features and sustainability innovations

Market Projections

Industry Outlook:

- Continued growth in eco-conscious consumer segments

- Expansion into emerging markets

- Integration of health and wellness features

- Premium positioning for sustainable products

Frequently Asked Questions

Are all stainless steel bottles made in China?

No, while China produces 99% of stainless steel water bottles globally, some are manufactured in other countries. However, the overwhelming majority, including popular brands like Hydro Flask, Stanley, and Klean Kanteen, are produced in China due to cost advantages and manufacturing capabilities.

Is Hydro Flask made in China?

Yes, Hydro Flask water bottles are manufactured in China, despite being an American brand founded in Oregon. The company moved production overseas to remain competitive while maintaining quality standards through strict supplier partnerships.

What water bottles are made in the USA?

Very few stainless steel water bottles are made in the USA. Liberty Works is one notable exception, producing vacuum-insulated bottles in Washington state. Most USA production focuses on plastic bottles, with Nalgene being the primary example for domestic plastic bottle manufacturing.

Who makes the best water bottles?

The "best" depends on your priorities. For premium quality and innovation, brands like Hydro Flask, Stanley, and Yeti (all made in China) lead the market. For USA-made options, Liberty Works offers excellent quality. For customization and B2B solutions, manufacturers like Sibottle provide comprehensive OEM/ODM services.

Where does Hydro Flask get their stainless steel?

Hydro Flask sources high-grade 18/8 (304) stainless steel primarily from certified suppliers in China, where the majority of global stainless steel production occurs. This ensures consistent quality and cost-effectiveness for their manufacturing partners.

Making the Right Choice for Your Needs

Whether you're a consumer or business buyer, understanding manufacturing origins helps make informed decisions.

Consumer Guidance

For Individual Buyers:

- Focus on certifications (FDA, LFGB) over manufacturing location

- Consider your budget and feature requirements

- Look for established brands with quality reputations

- Check warranty and customer service availability

Quality Indicators to Prioritize:

- Food-grade stainless steel construction

- Effective insulation performance

- Leak-proof design and testing

- Brand reputation and reviews

Business Buyer Considerations

For B2B Purchases:

- Evaluate total cost of ownership, not just unit price

- Consider customization requirements and capabilities

- Assess supplier reliability and communication

- Review quality certifications and testing protocols

Key Partnership Factors:

- Minimum order quantities that match your needs

- Lead times that support your business cycles

- Communication responsiveness and language capabilities

- Quality consistency across multiple orders

Sourcing Strategy:

- Start with samples to evaluate quality

- Visit facilities when possible for relationship building

- Establish clear quality specifications and testing requirements

- Develop long-term partnerships for better pricing and service

From my experience working with clients globally, successful partnerships focus on long-term value rather than just initial cost savings.

Conclusion

Understanding where stainless steel water bottles are manufactured empowers better decision-making for both consumers and businesses. While China dominates with 99% of global production, this concentration brings advantages in cost, technology, and customization capabilities that benefit buyers worldwide.

The key isn't avoiding Chinese manufacturing but rather finding reputable manufacturers who prioritize quality, safety, and customer service. Whether you're sourcing for personal use or business needs, focus on certifications, testing protocols, and supplier relationships rather than manufacturing location alone.

Ready to Source Your Perfect Stainless Steel Water Bottles?

If you're a business looking for reliable, high-quality stainless steel water bottle manufacturing, I invite you to explore how Sibottle can support your needs. With 14+ years of expertise, 1000+ available designs, and comprehensive OEM/ODM services, we help businesses create exceptional products that reflect their brand values.

Get Started Today:

- Browse our extensive product catalog

- Request samples to evaluate our quality firsthand

- Contact our team for personalized consultation

- Discover our complete manufacturing capabilities

Whether you need 1,000 pieces or 500,000, we're equipped to deliver exceptional quality with competitive pricing and reliable service. Let's create something amazing together.

Reference: